System and method for carrying out prefabrication and field assembly in electromechanical pipe network factory based on building information modeling (BIM)

A technology of electromechanical pipe network and factory prefabrication, applied in computer-aided design, electrical digital data processing, details related to processing steps, etc., can solve problems such as low efficiency, high energy consumption, high pollution, etc., and improve the level of mechanization and mechanical equipment Effects of Utilization Improvement, Rational Use and Management of Materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

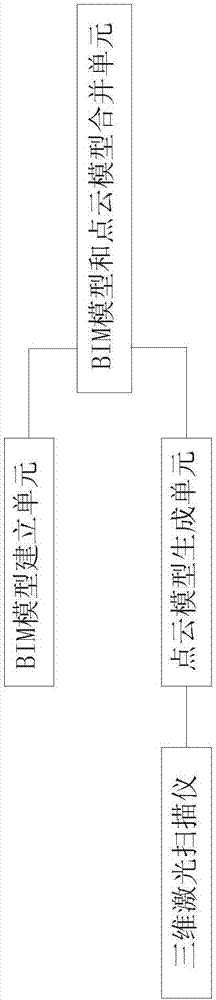

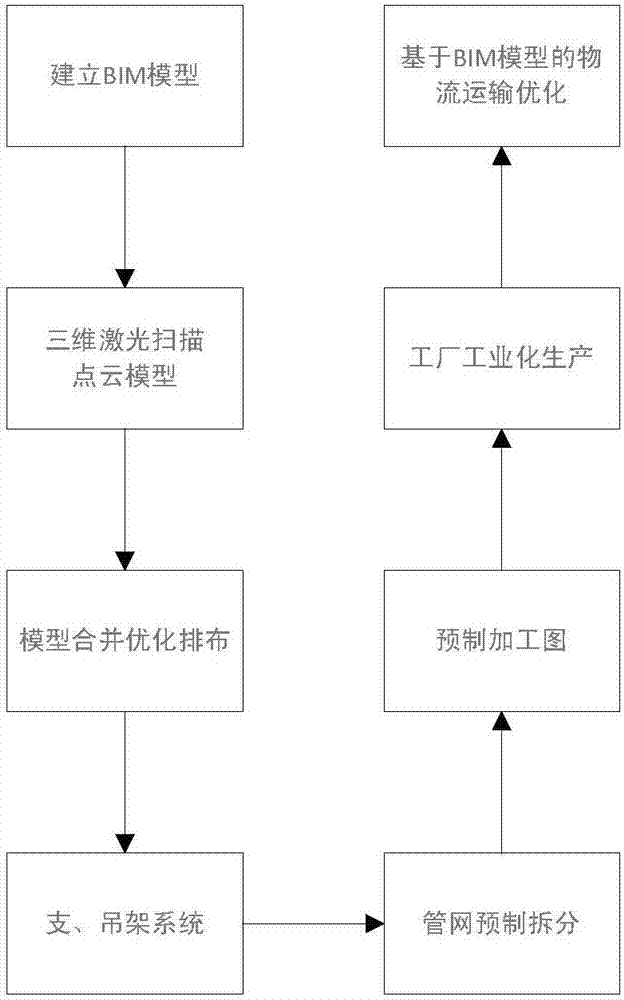

[0029] Such as figure 1 As shown, a BIM-based electromechanical pipe network factory prefabrication on-site assembly system includes a BIM model building unit, a 3D laser scanner, a point cloud model generation unit, a BIM model and a point cloud model merging unit;

[0030] The BIM model building unit is used to establish a BIM building information model according to the building structure of the building body and the layout of the electromechanical pipe network;

[0031] The three-dimensional laser scanner is used to perform three-dimensional laser measurement on the building structure of the building and transmit it to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com