Biological treatment method of papermaking-method reconstituted tobacco raw materials and pulp

A technology for biological treatment and reconstitution of tobacco leaves, applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of low internal quality, insufficient aroma, and large irritation, and achieve good internal quality, improved physical properties, and high irritation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Weigh 50 parts of tobacco stems and 50 parts of tobacco dust (including 40 parts of tobacco leaf fragments and 10 parts of tobacco dust) according to the absolute dry weight (ie weight), and perform a water extraction respectively. The technical conditions for primary extraction of tobacco stems are solid-liquid ratio of 1:8, temperature of 70°C, and time of 50 minutes. The primary extraction process conditions of tobacco raw materials such as tobacco leaf fragments and tobacco powder are as follows: temperature 60°C, solid-liquid ratio 1:5, and time 50 minutes. The dryness after one-time extraction and squeezing of tobacco stems is 25%, the dryness of tobacco leaf fragments and tobacco dust after one-time extraction and squeezing is 30%, the yield of tobacco stem extract is 45%, and the extraction of tobacco leaf fragments and tobacco dust The yield of the product is 50%.

[0055] After the tobacco stems are extracted once, they are processed by rubbing. After rubbing...

Embodiment 2

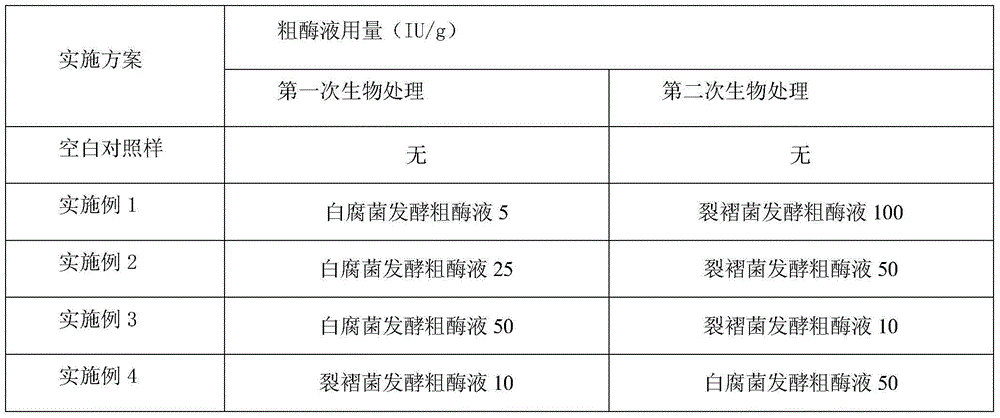

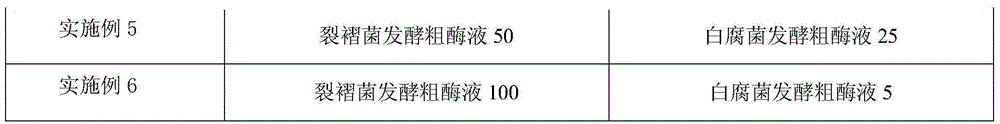

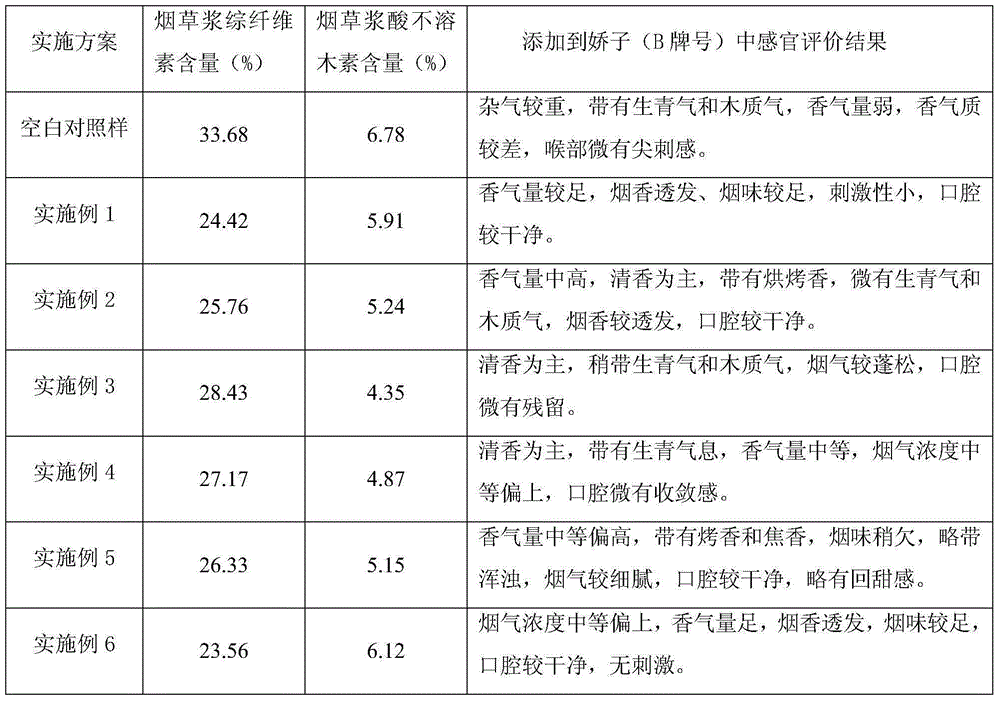

[0062] Compared with Example 1, only the following treatment methods are changed in this embodiment, and other treatment conditions are unchanged: the amount of fermented crude enzyme liquid of white rot fungus is changed to 25 IU / g, and the amount of fermented crude enzyme liquid of Schizophyllum fermented to 50 IU / g. Except for the above-mentioned changes in the treatment conditions, other treatment conditions remained unchanged, and the scheme of Example 1 was repeated, and the final sensory evaluations obtained are shown in Table 2. After adopting the two biological treatment schemes of this example, the cigarette has a sufficient aroma, with a roasted aroma, a slight woody smell mixed into the aroma, a better sweetness, a more transparent smoke aroma, and a cleaner mouth.

Embodiment 3

[0064] Change the amount of white rot fungus fermented crude enzyme liquid to 50IU / g, the amount of Schizophyllum fermented fermented crude enzyme liquid to 10IU / g, and other treatment conditions remain unchanged, that is, the same as Example 1, repeat the scheme of Example 1, and finally obtain See Table 2 for sensory evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com