Biochemical joint preparation method and application of absolute rose oil

A biochemical and joint preparation technology is applied in the field of biochemical joint preparation of rose absolute to achieve the effect of pure aroma, less impurities and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

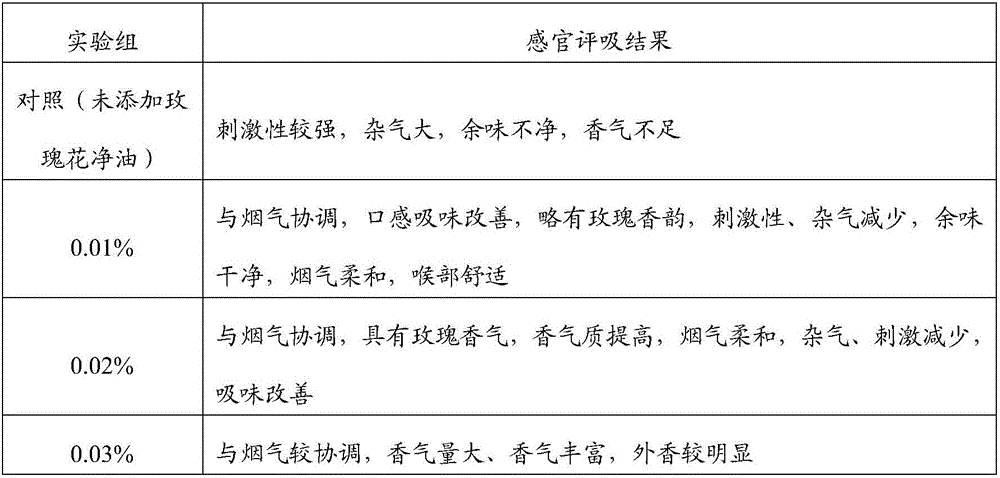

Embodiment 1

[0023] A biochemical joint preparation method of rose absolute, comprising the following steps:

[0024] 1) Compound enzyme fermentation: Grind roses into 40-mesh coarse powder with a high-speed pulverizer, put them into an extraction tank, add water with a mass ratio of 1:30, and add compound enzymes according to 0.05% of the mass of roses, and stir evenly , under the natural conditions of 45°C and pH, ferment for 6 hours to obtain rose flower fermentation liquid;

[0025] The compound enzyme is: β-glucosidase (food grade, enzyme activity 1000u / g), amylase (food grade, enzyme activity 100,000u / g), cellulase (food grade, enzyme activity 200,000u / g) g), mixed according to the mass ratio of 3:1:1, accounting for 0.03%, 0.01% and 0.01% of the rose mass respectively;

[0026] 2) Reflux extraction and Maillard reaction: reflux extraction of rose flower fermentation broth at 100°C for 3 hours, at which temperature the enzyme is inactivated; then adjust the pH value to 12, perform M...

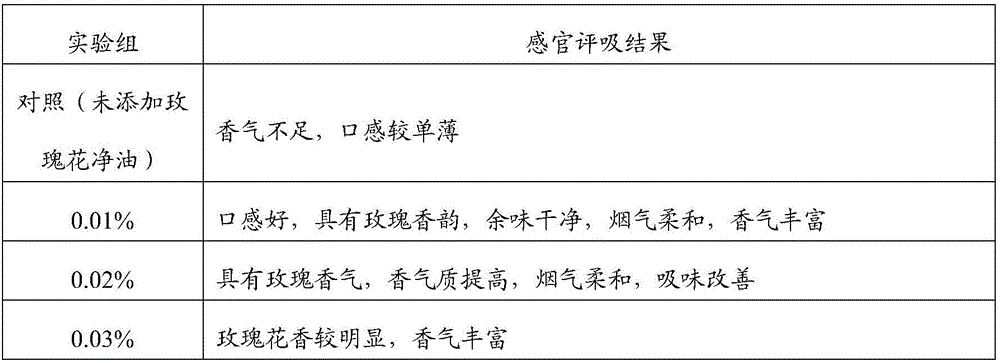

Embodiment 2

[0032] A biochemical joint preparation method of rose absolute, comprising the following steps:

[0033] 1) Compound enzyme fermentation: Grind roses into 60-mesh coarse powder with a high-speed pulverizer, put them into an extraction tank, add water with a mass ratio of 1:40, and add compound enzymes according to 0.14% of the mass of roses, and stir evenly , under natural conditions of 50°C and pH, ferment for 8 hours to obtain rose flower fermentation liquid;

[0034] The compound enzyme is: β-glucosidase (food grade, enzyme activity 800u / g), amylase (food grade, enzyme activity 80,000 u / g), cellulase (food grade, enzyme activity 150,000 u / g) g), mixed according to the mass ratio of 5:1:1, accounting for 0.1%, 0.02% and 0.02% of the rose mass respectively;

[0035] 2) Reflux extraction and Maillard reaction: reflux extraction of rose flower fermentation broth at 100°C for 3.5 hours, at which temperature the enzyme is inactivated; then adjust the pH value to 13, carry out Mail...

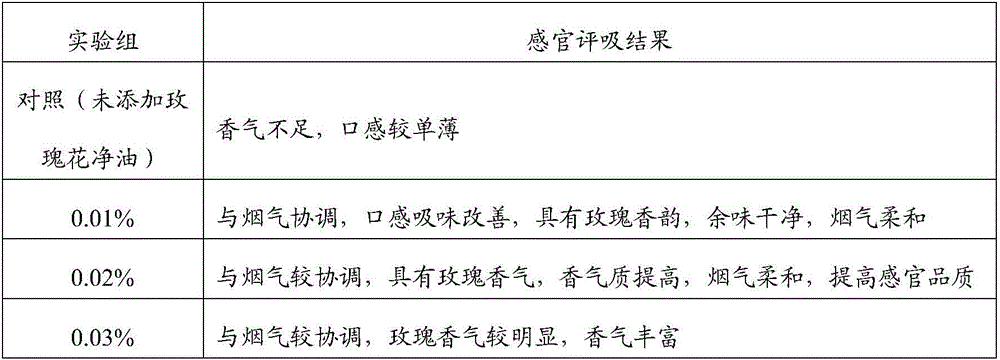

Embodiment 3

[0041] A biochemical joint preparation method of rose absolute, comprising the following steps:

[0042] 1) Compound enzyme fermentation: Grind roses into 80-mesh coarse powder with a high-speed pulverizer, put them into an extraction tank, add water with a mass ratio of 1:20, and add compound enzymes according to 0.2% of the mass of roses, and stir evenly , under the natural conditions of 55°C and pH, ferment for 12 hours to obtain rose flower fermentation liquid;

[0043] The compound enzyme is: β-glucosidase (food grade, enzyme activity 500u / g), amylase (food grade, enzyme activity 60,000 u / g), cellulase (food grade, enzyme activity 120,000 u / g) g), mixed according to the mass ratio of 2:1:1, accounting for 0.1%, 0.05% and 0.05% of the rose mass respectively;

[0044] 2) Reflux extraction and Maillard reaction: reflux extraction of rose flower fermentation liquid at 100°C for 4 hours, and enzyme inactivation at this temperature; then adjust the pH value to 10, perform Mail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com