Solid waste pyrolysis and related gas combustion device

A solid waste and combustion device technology, applied in the field of energy saving and environmental protection, can solve the problems of large consumption, secondary pollution, hindering pyrolysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

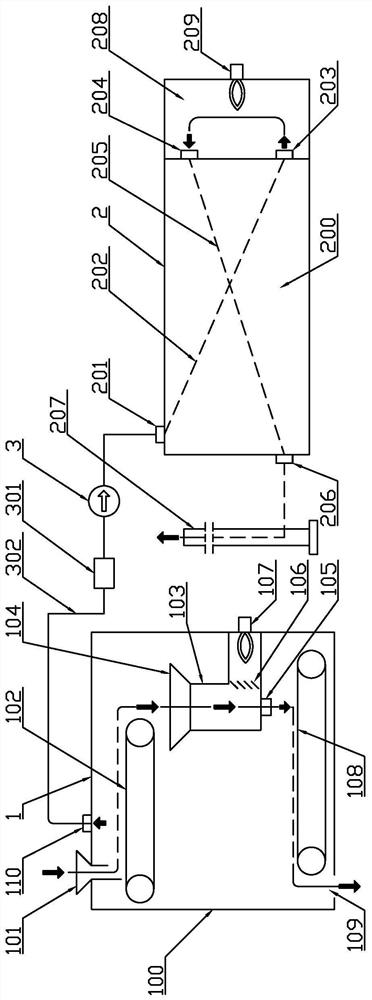

[0027] Embodiment 1: as figure 1 , a solid waste pyrolysis and related gas combustion device, including a solid processor 1, a gas burner 2 and a fan 3, the solid processor 1 includes a housing 100, a raw material conveying mechanism 102, a pyrolysis furnace 103, The slag conveying mechanism 108; the raw material conveying mechanism 102, the pyrolysis furnace 103, its inlet 104, the outlet 105, and the slag conveying mechanism 108 are all arranged in the housing 100; the housing 100 is provided with a raw material inlet 101 and a slag outlet 109 And the exhaust port 110; the raw material inlet 101 sends the raw material to the inlet of the pyrolysis furnace 103 through the raw material delivery mechanism 102, and the outlet of the pyrolysis furnace 103 delivers the raw material to the slag outlet 109 through the slag delivery mechanism 108; the described The air outlet 110 is located near the raw material inlet 101, and the air outlet 110 is located above the pyrolysis furnace...

Embodiment 2

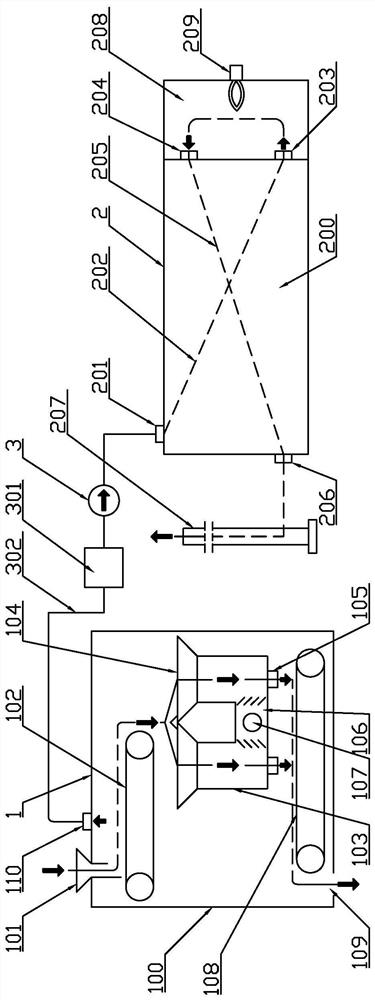

[0044] Embodiment 2: as figure 2 : A solid waste pyrolysis and related gas combustion device, including a solid processor 1, a gas burner 2 and a fan 3, the solid processor 1 includes a housing 100, a raw material delivery mechanism 102, a pyrolysis furnace 103, Slag conveying mechanism 108; described raw material conveying mechanism 102, pyrolysis furnace 103 and its inlet 104, outlet 105, and slag conveying mechanism 108 are all arranged in the housing 100; described housing 100 is provided with raw material inlet 101, outlet A slag port 109 and an exhaust port 110; the raw material inlet 101 sends the raw material to the inlet of the pyrolysis furnace 103 through the raw material delivery mechanism 102, and the outlet of the pyrolysis furnace 103 delivers the raw material to the slag outlet 109 through the slag delivery mechanism 108; The air exhaust port 110 is located near the raw material inlet 101; the air exhaust port 110 is located above the pyrolysis furnace inlet; ...

Embodiment 3

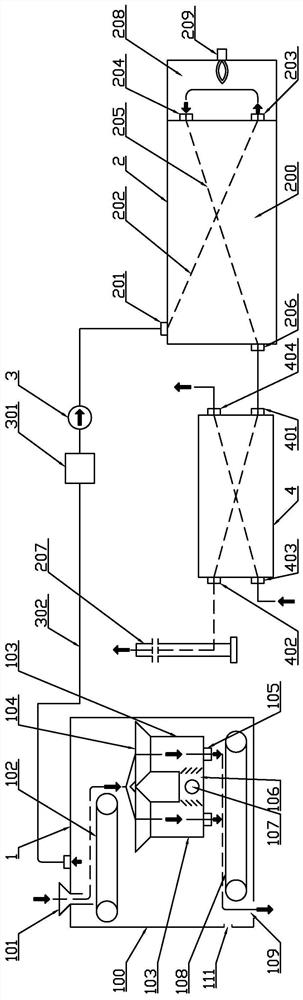

[0055] Embodiment 3: as image 3 : A solid waste pyrolysis and related gas combustion device, including a solid processor 1, a gas burner 2 and a fan 3, the solid processor 1 includes a housing 100, a raw material delivery mechanism 102, a pyrolysis furnace 103, Slag conveying mechanism 108; described raw material conveying mechanism 102, pyrolysis furnace 103 and its inlet 104, outlet 105, and slag conveying mechanism 108 are all arranged in the housing 100; described housing 100 is provided with raw material inlet 101, outlet Slag port 109, air exhaust port 110 and external waste gas suction port 111; described raw material inlet 101 sends raw material to the inlet of pyrolysis furnace 103 through raw material conveying mechanism 102, and its outlet of pyrolytic furnace 103 conveys raw material through slag conveying mechanism 108 to the slag outlet 109; the air exhaust port 110 is located near the position of the raw material inlet 101; the air exhaust port 110 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com