Paper cigarette filter stick containing collagen fibers and preparation method thereof

A technology of collagen fibers and cigarette filter rods, which is applied in the manufacture of cigarettes, fiber chemical characteristics, organic non-cellulose fibers, etc., can solve the problems affecting paper quality and performance, collagen fiber bundles cannot be fully opened, and fiber interstitial cannot be completely Eliminate and other problems to achieve the effect of increasing the added value of the product, improving the sweetness, reducing the content of tar and harmful ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

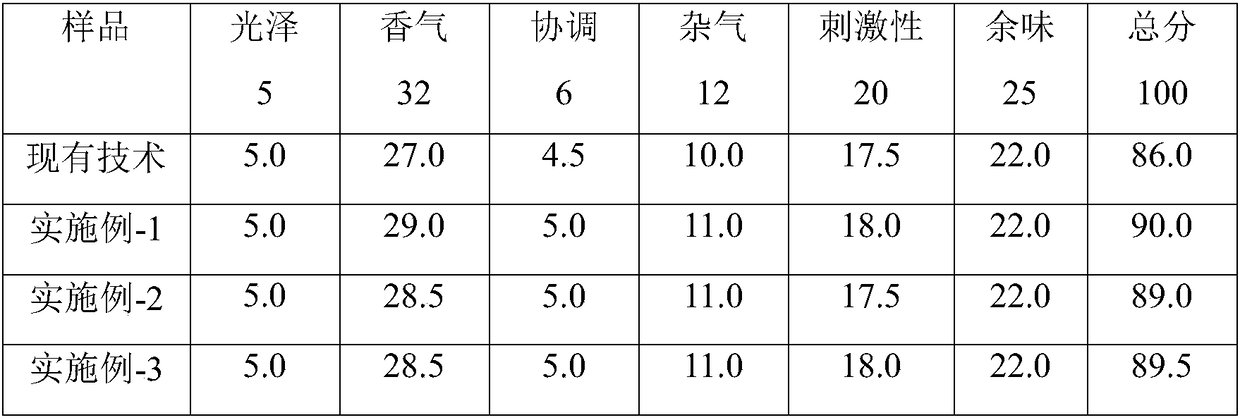

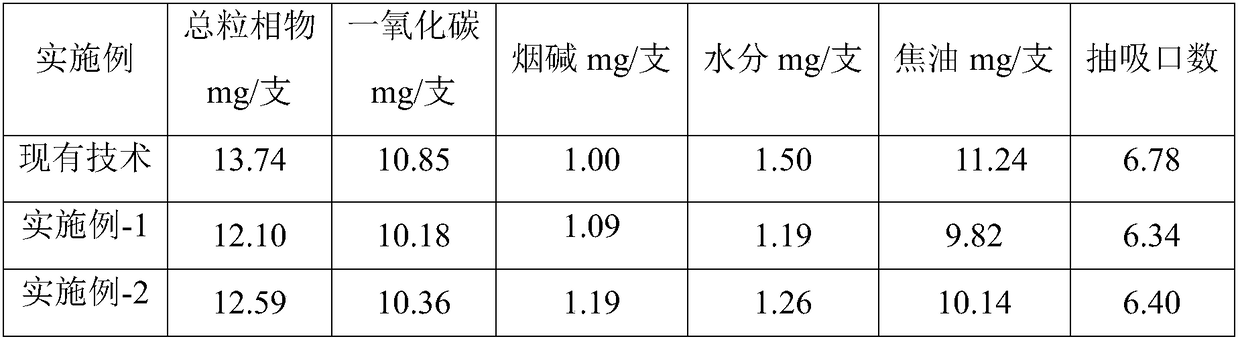

Examples

Embodiment 1

[0017] (1) Preparation of collagen fiber: liming: make the two-layer gray skin sheet of cowhide into 1.5mm thick, put it into the drum, add water with 100% to 200% gray skin weight and 1% to 4% slaked lime, and rotate it for 12 hours at room temperature. ~18 hours; deliming: control water, add 200% water of gray skin weight and 0.1%~0.5% ammonium sulfate, rotate for 20~24 hours; control water, add water 100%~150% gray skin weight, 0.1 %~0.5% non-ionic degreaser and 2%~3% ammonium sulfate, rotate for 1.5 hours; softening: control water, add 50% water of gray skin weight, 0.5% ammonium sulfate and 1.0%~1.5% softening Enzyme, rotate for 30 minutes; water washing: control water, add 200% to 300% water, wash with water for 20 minutes; demineralization: control water, add deionized water with 100% gray leather weight, and rotate for 4 to 6 hours; Add water, add absolute ethanol with 100% gray skin weight, and rotate for 2 hours. This operation must be carried out several times, and ...

Embodiment 2

[0021] (1) Preparation of collagen fiber: liming: make the two-layer gray skin sheet of cowhide into 1.5mm thick, put it into the drum, add water with 100% to 200% gray skin weight and 1% to 4% slaked lime, and rotate it for 12 hours at room temperature. ~18 hours; deliming: control water, add 200% water of gray skin weight and 0.1%~0.5% ammonium sulfate, rotate for 20~24 hours; control water, add water 100%~150% gray skin weight, 0.1 %~0.5% non-ionic degreaser and 2%~3% ammonium sulfate, rotate for 1.5 hours; softening: control water, add 50% water of gray skin weight, 0.5% ammonium sulfate and 1.0%~1.5% softening Enzyme, rotate for 30 minutes; water washing: control water, add 200% to 300% water, wash with water for 20 minutes; demineralization: control water, add deionized water with 100% gray leather weight, and rotate for 4 to 6 hours; Water, add absolute ethanol with 100% weight of the gray hide, and rotate for 2 hours. This operation must be carried out several times, a...

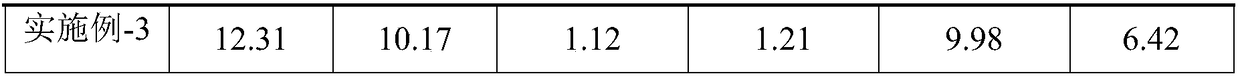

Embodiment 3

[0025] (1) Preparation of collagen fiber: liming: make the two-layer gray skin sheet of cowhide into 1.5mm thick, put it into the drum, add water with 100% to 200% gray skin weight and 1% to 4% slaked lime, and rotate it for 12 hours at room temperature. ~18 hours; deliming: control water, add 200% water of gray skin weight and 0.1%~0.5% ammonium sulfate, rotate for 20~24 hours; control water, add water 100%~150% gray skin weight, 0.1 %~0.5% non-ionic degreaser and 2%~3% ammonium sulfate, rotate for 1.5 hours; softening: control water, add 50% water of gray skin weight, 0.5% ammonium sulfate and 1.0%~1.5% softening Enzyme, rotate for 30 minutes; water washing: control water, add 200% to 300% water, wash with water for 20 minutes; demineralization: control water, add deionized water with 100% gray leather weight, and rotate for 4 to 6 hours; Water, add absolute ethanol with 100% weight of the gray hide, and rotate for 2 hours. This operation must be carried out several times, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com