Urban river sludge treatment method

A technology of river silt and treatment method, which is applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., to achieve the effect of enhancing strength, improving properties and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

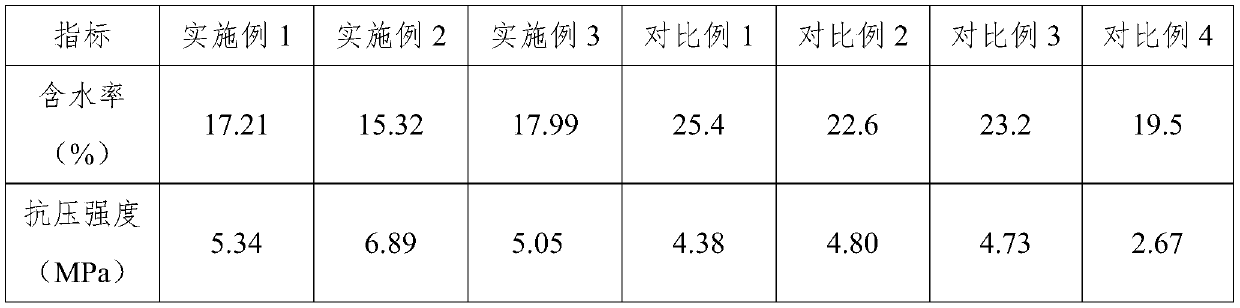

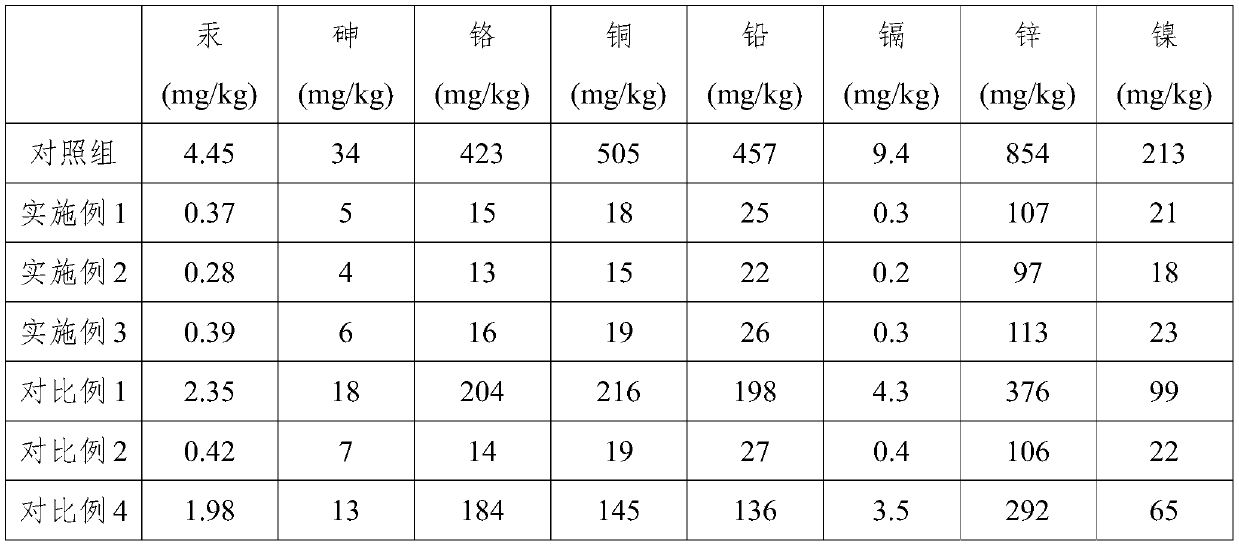

Examples

Embodiment 1

[0035] Embodiment 1, a kind of urban river silt treatment method

[0036] S1 collects the silt in the river channel and puts it in a storage tank, removes impurities from the silt, concentrates it and stirs it to obtain mud;

[0037] S2 adds hydroxypropyl methylcellulose to the mud obtained in step S1, the addition of said hydroxypropyl methylcellulose is 2% of the total weight of the mud, and stirs for 35min to obtain mud I;

[0038] S3 evenly sprays the phosphoric acid solution on the surface of the mud I obtained in step S2, the liquid-solid ratio of the phosphoric acid solution and the mud is 0.8ml:1g, and the concentration of the phosphoric acid solution is a phosphoric acid aqueous solution with a volume concentration of 20%, and then adding Potassium permanganate, the solid-to-liquid ratio of described potassium permanganate and phosphoric acid solution is 1g:6ml, leaves standstill 30min, gets mud II;

[0039] S4 adds hydroxyethylethylenediamine to the mud II obtained ...

Embodiment 2

[0041] Embodiment 2, a kind of urban river silt treatment method

[0042] S1 collects the silt in the river channel and puts it in a storage tank, removes impurities from the silt, concentrates it and stirs it to obtain mud;

[0043] S2 adds hydroxypropyl methylcellulose to the mud obtained in step S1, the addition of said hydroxypropyl methylcellulose is 3% of the total weight of the mud, and stirs for 30min to obtain mud I;

[0044] S3 uniformly sprays the phosphoric acid solution on the surface of the mud I obtained in step S2, the liquid-solid ratio of the phosphoric acid solution and the mud is 0.8ml:1g, and the concentration of the phosphoric acid solution is a phosphoric acid aqueous solution with a volume concentration of 30%, and then adding Potassium permanganate, the solid-to-liquid ratio of described potassium permanganate and phosphoric acid solution is 1g:6ml, leaves standstill 25min, gets mud II;

[0045] S4 adds hydroxyethylethylenediamine to the mud II obtain...

Embodiment 3

[0047] Embodiment 3, a kind of urban river silt treatment method

[0048] S1 collects the silt in the river channel and puts it in a storage tank, removes impurities from the silt, concentrates it and stirs it to obtain mud;

[0049] S2 adds hydroxypropyl methylcellulose to the mud obtained in step S1, the addition of said hydroxypropyl methylcellulose is 4% of the total weight of the mud, and stirs for 25min to obtain mud I;

[0050] S3 uniformly sprays phosphoric acid solution on the mud I surface that step S2 obtains, and the liquid-solid ratio of described phosphoric acid solution and mud is 0.8ml:1g, and the concentration volume concentration of described phosphoric acid solution is the phosphoric acid aqueous solution of 30%, then adds high Potassium manganate, the solid-to-liquid ratio of described potassium permanganate and phosphoric acid solution is 1g:6ml, leaves standstill 20min, gets mud II;

[0051] S4 adds hydroxyethylethylenediamine to the mud II obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com