Micro emulsion fuel production process and formula

A production process and microemulsion technology, applied in the field of fuel oil, can solve problems such as calorific value, content of harmful components in production cost, and unsatisfactory chroma, and achieve the effects of low production cost, sufficient combustion, and low content of harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

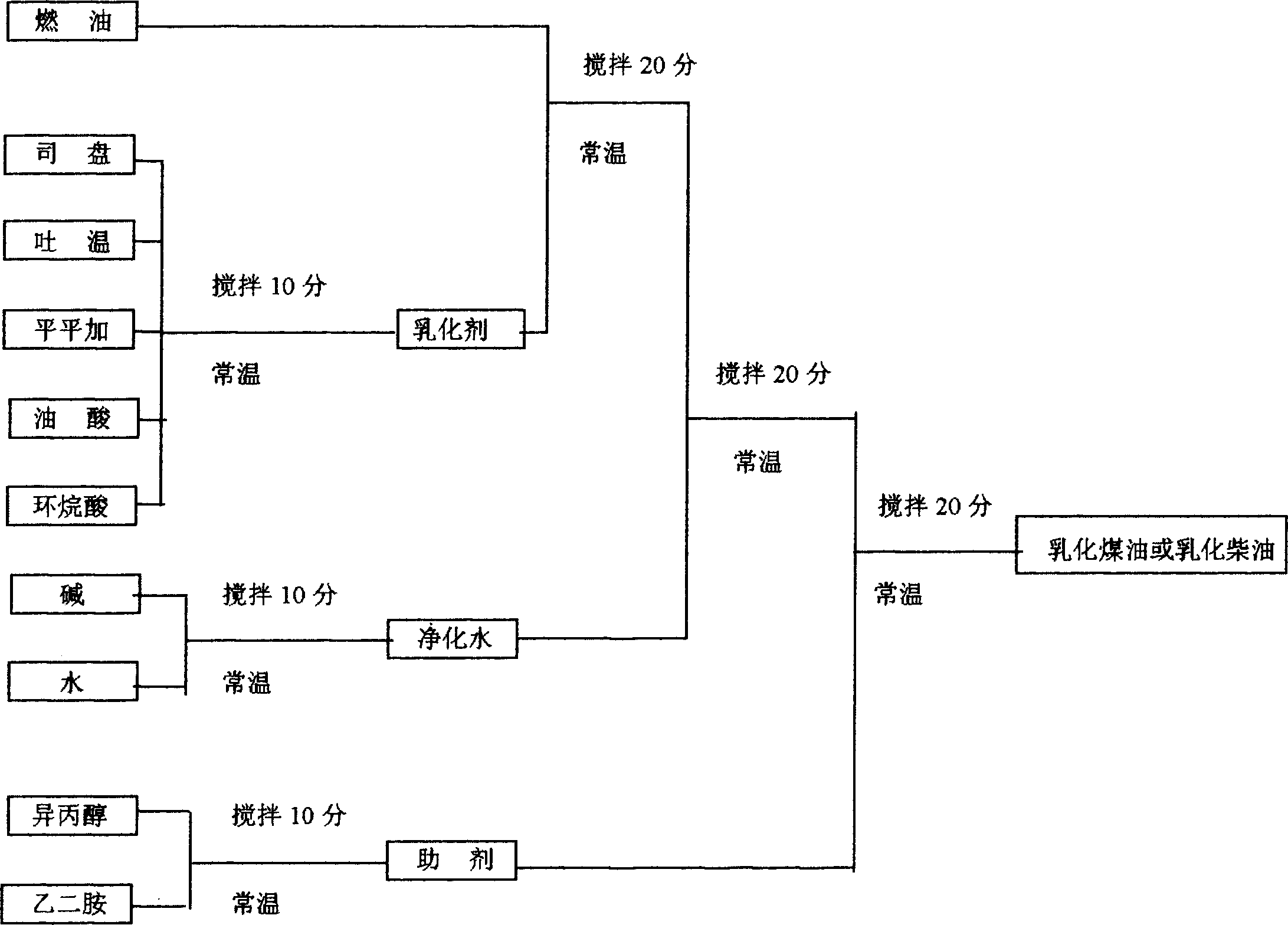

Method used

Image

Examples

example 1

[0009] Example 1, the proportioning of microemulsified kerosene, by weight, kerosene is 76%, emulsifier is 8.25%, purified water is 15%, and auxiliary agent is 0.75%. The proportion of emulsifier by weight is 12.7% for Span, 3.6% for Tween, 1.8% for oil, and 81.9% for naphthene.

example 2

[0010] Example 2, the proportioning of micro-emulsion diesel oil, by weight, diesel oil is 76%, emulsifier is 8.75%, purified water is 15%, and auxiliary agent is 0.75%. The proportion of emulsifiers by weight is 12.7% for Span, 1.8% for Tween, 1.8% for Pinpina, 1.8% for oil, and 81.9% for naphthene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com