Additive for improving slagging feature of high-iron Zhundong coal and application method thereof

An application method and additive technology, which is applied in the direction of fuel additives, combustion methods, fuel supply, etc., can solve the difficulty of estimating the degree of chemical reaction between additives and flue gas, low melting point substances or low-temperature eutectics, and increased Zhundong coal combustion costs, etc. problems, to achieve the effect of improving slagging characteristics, low cost, and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Additive components and the mass percent of each component are as shown in Table 1:

[0042] Table 1, embodiment 1 additive component and mass percent

[0043] components aluminum gray magnesium oxide dolomite unit % % % Compared with high-speed railway Zhundong coal quality ratio 1 3 2 Percentage of additive mass 15-20 50 30-35

[0044] The mass ratio of additives to high-speed Zhundong coal is 6:100, the average particle size of aluminum ash is less than 200 μm, the average particle size of magnesium oxide is less than 20 μm, and the average particle size of dolomite is less than 75 μm. The additive in Example 1 can increase the softening temperature of high-speed iron Zhundong coal ash by 60°C or above.

Embodiment 2

[0046] Additive component and the mass percent of each component are as shown in table 2:

[0047] Table 2, embodiment 2 additive components and mass percent

[0048] components aluminum gray magnesium oxide dolomite unit % % % Compared with high-speed railway Zhundong coal quality ratio 2 1 1 Percentage of additive mass 50 25 25

[0049] The mass ratio of additives to high-speed Zhundong coal is 4:100, the average particle size of aluminum ash is less than 200 μm, the average particle size of magnesium oxide is less than 20 μm, and the average particle size of dolomite is less than 150 μm. The additive in Example 2 can increase the softening temperature of high-speed iron Zhundong coal ash by 80°C or above.

Embodiment 3

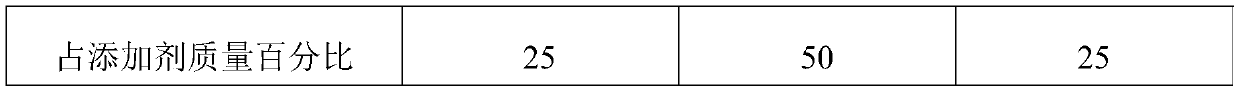

[0051] Additive components and the mass percent of each component are as shown in table 3:

[0052] Table 3, embodiment 3 additive components and mass percent

[0053]

[0054]

[0055] The mass ratio of additives to high-speed Zhundong coal is 8:100, the average particle size of aluminum ash is less than 150 μm, the average particle size of magnesium oxide is less than 50 μm, and the average particle size of dolomite is less than 75 μm. The additive in Example 3 can increase the softening temperature of high-speed iron Zhundong coal ash by 80°C or above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com