Segmented coupling and gasification device and method of fault coal water-cooling fireplace

A gasification device and low-quality coal technology, applied in the direction of gasification process, granular/powdered fuel gasification, combined combustion mitigation, etc., can solve the problem of non-adjustable H2/CO ratio, high initial investment and operating costs, and load adaptability Low-level problems, to achieve the effect of improving slagging characteristics, strong adaptability of raw materials, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

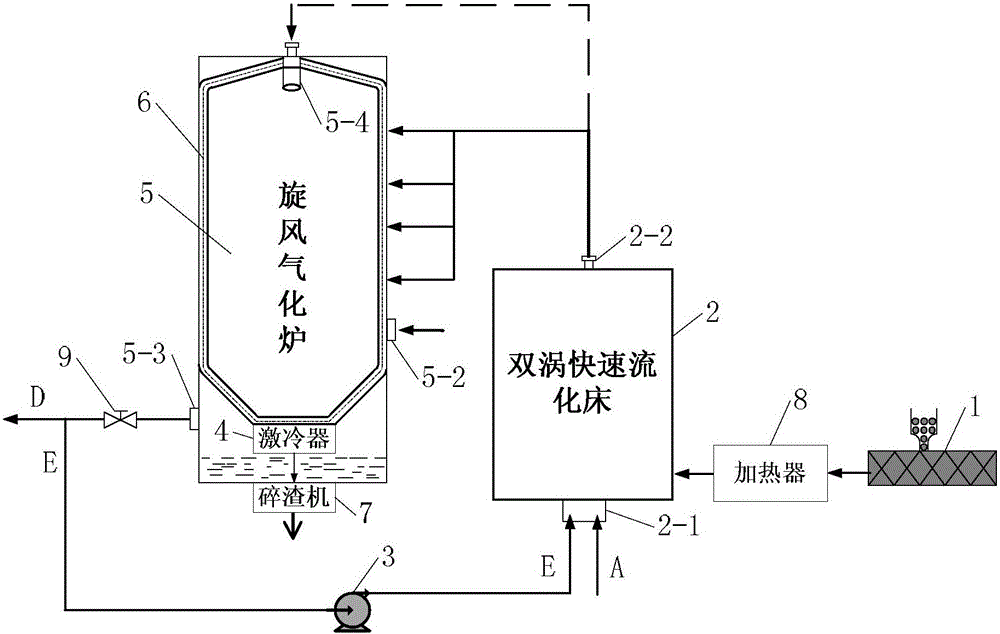

[0085] Specific implementation mode two: see figure 1 This embodiment is described. The difference between this embodiment and the low-quality coal water-cooled fireplace segmented coupled gasification device described in Embodiment 1 is that the optimum working temperature of the cyclone gasifier 5 is 1550°C.

[0086] In this embodiment, the equilibrium analysis shows that when Inner Mongolia lignite is used as the raw material, when the working temperature of the twin-vortex fast fluidized bed is 800°C, the optimum working temperature of the cyclone gasifier 5 is 1554°C, and the carbon conversion rate is as high as 98.9%. The oxygen consumption is 0.301, the effective gas ratio is 96.8%, and the cold gas efficiency is 83%.

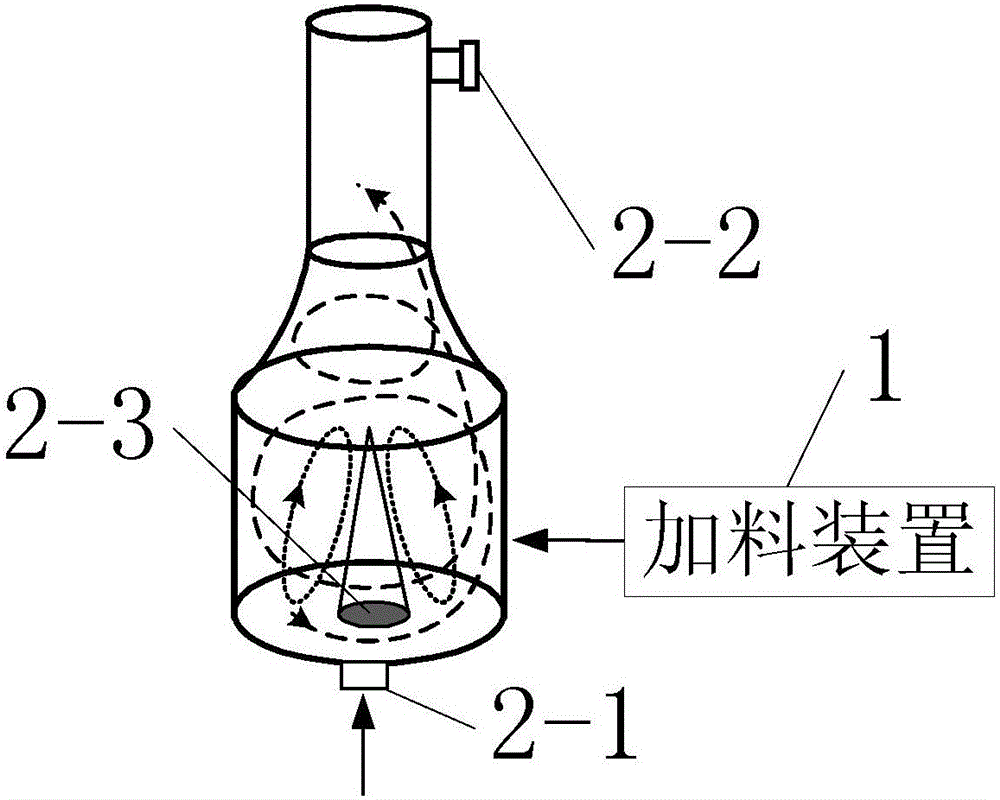

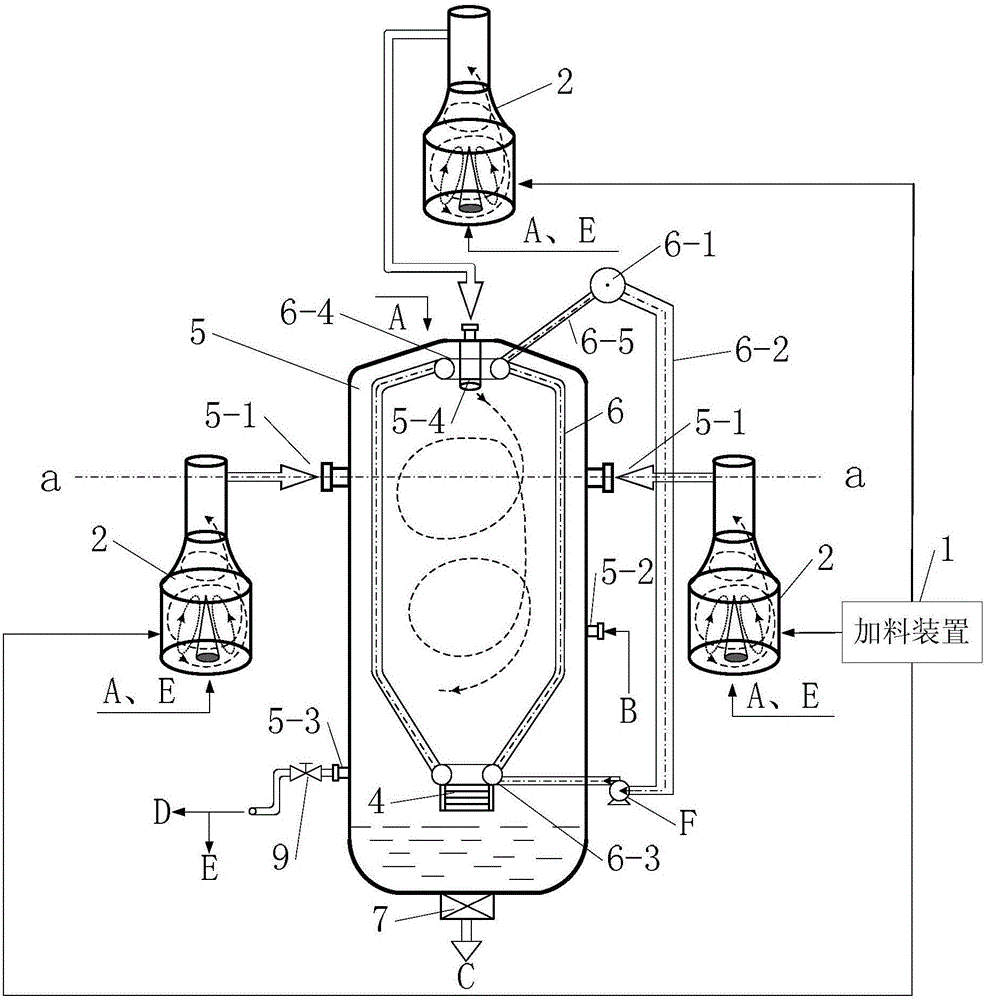

[0087] Specific implementation mode three: see figure 1 and figure 2 To illustrate this embodiment, the difference between this embodiment and the low-quality coal water-cooled fireplace segmented coupled gasification device described in Embodiment 1 ...

specific Embodiment approach 9

[0102] Embodiment 9: The difference between this embodiment and the segmented coupled gasification device for low-quality coal water-cooled fireplaces described in Embodiment 1 is that the water cooling system 6 adopts natural circulation and forced circulation operation, wherein the standpipe The water cooling wall 6-6 can be replaced by a coil type forced circulation water cooling wall.

specific Embodiment approach 10

[0103] Embodiment 10: The difference between this embodiment and the low-quality coal water-cooled fireplace segmented coupling gasification device described in Embodiment 3 is that the No. 1 gasification agent inlet from the twin-vortex fast fluidized bed 2 is 2-1 The incoming gas moves spirally from bottom to top.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com