Method for treating shred of tobacco stems

A processing method and technology for cut tobacco stems, applied in the processing field of tobacco stems, can solve the problems of large difference in shape and color of cut stems, uneven blending of cut leaves and cut stems, damage to the internal structure of tobacco stems, etc. Production cost, improve blending uniformity and stability, and ensure the effect of blending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

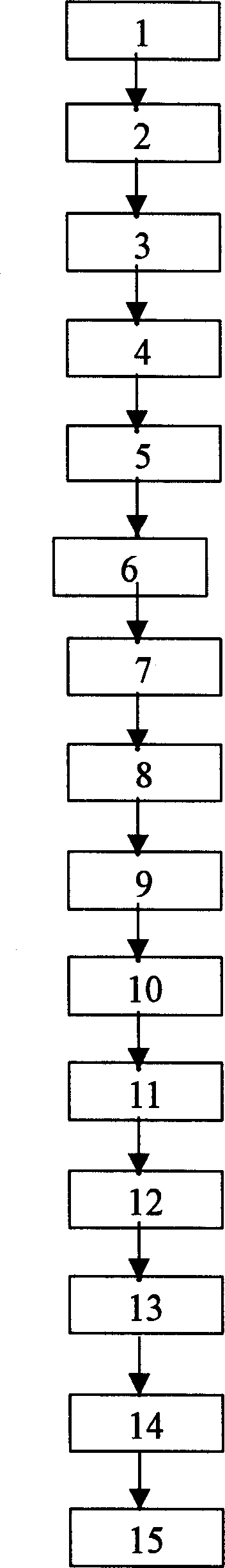

[0010] figure 1 The contents indicated by the labels are as follows:

[0011] 1-quantitative feeding, 2-screening, 3-washing stems, 4-storage stems, 5-quantitative feeding, 6-cutting stems, 7-quantitative feeding, 8-stem feeding, 9-cutting stems , 10-quantitative feeding, 11-flash steaming, 12-expansion tower, 13-screening, 14-floating air delivery, 15-storage shredded stems.

[0012] The above steps 4-the moisture content of the cut stems after storage is 36%, 6-the moisture content of the cut stems after cutting the stems is 36%, 7-the moisture content of the cut stems after quantitative feeding is 38%, 12-the moisture content of the cut stems after drying in the puffing tower is 13% . The puffing equipment adopts the YJ9102 stem shredded puffed drying tower.

[0013] 6-Stem cutting thickness 0.18mm (SQ36 curved blade hob type stem cutting machine) 9-Stem cutting width 2.00mm (SQ curved blade hob type stem cutting machine)

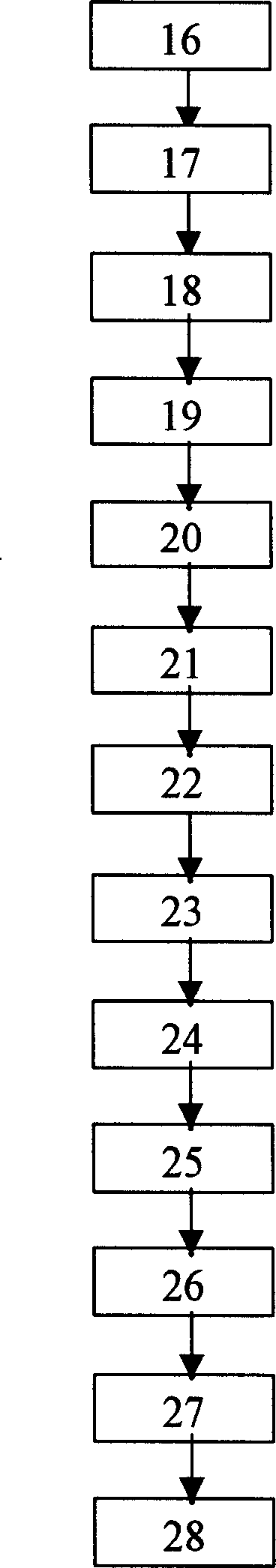

[0014] figure 2 The content indicated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com