Primary hot air heating system of secondary reheated fired coal power generation set

A technology of secondary reheating and generating sets, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased resistance of the primary air system, overheating of steam temperature, etc., and achieve cascade utilization, flexible control, The effect of enlarging the suitable range of coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with embodiment.

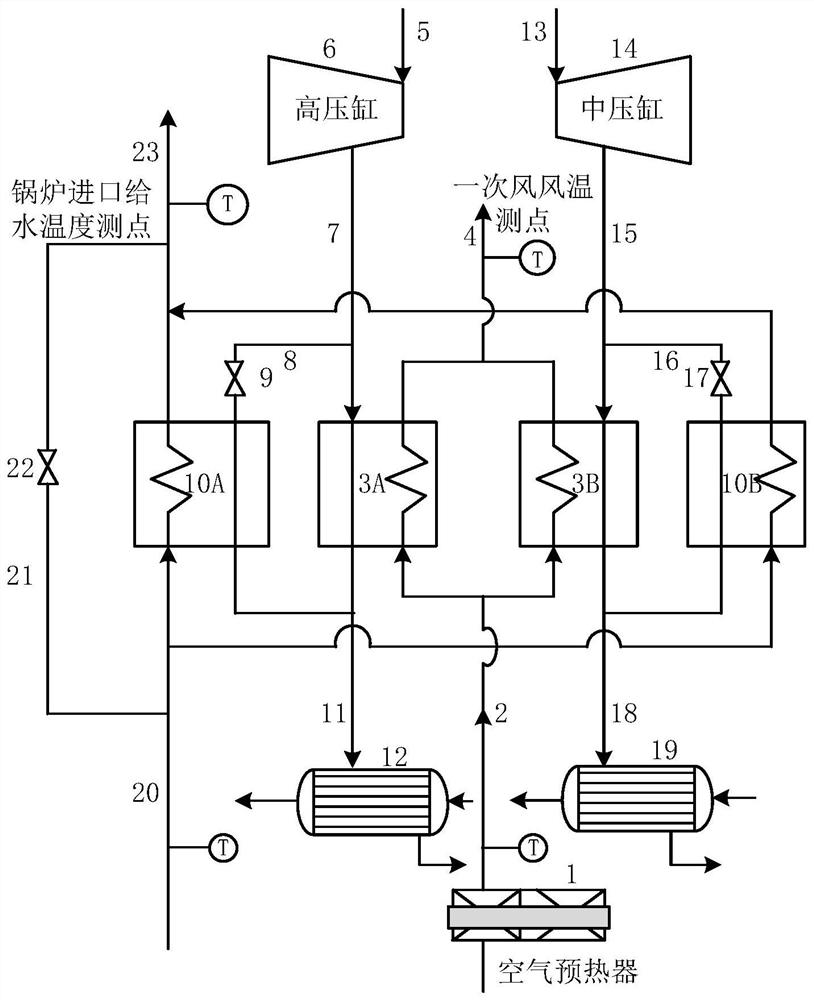

[0025] Such as figure 1 Shown: a hot primary air heating system for a coal-fired power unit with double reheating, including a steam turbine two-stage steam extraction system, a steam turbine four-stage steam extraction system, a hot primary air heating system and a feed water heating system. in;

[0026] The second-stage steam extraction of the steam turbine is divided into two paths, which are respectively connected to the inlet of the external steam cooler 10A and the hot primary air heater 3A. No. 2 high-pressure heater 12 inlet; the four-stage steam extraction of the steam turbine is also divided into two routes, which are respectively connected with the inlet of another set of external steam cooler 10B and the hot primary air heater 3B, and pass through the external steam cooler 10B and the heat After the primary air heater 3B is merged, it is connected to the inlet of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com