Method and system for generating coal blending and blending combustion scheme of load section coal-fired boiler

A technology for coal-fired boilers and loads, which is applied in the generation method and system of coal blending schemes for coal-fired boilers in the load section. It can solve the problems of low blending efficiency, insufficient fineness, and poor blending flexibility, and achieve an increase in blending ratio. , the effect of increasing enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

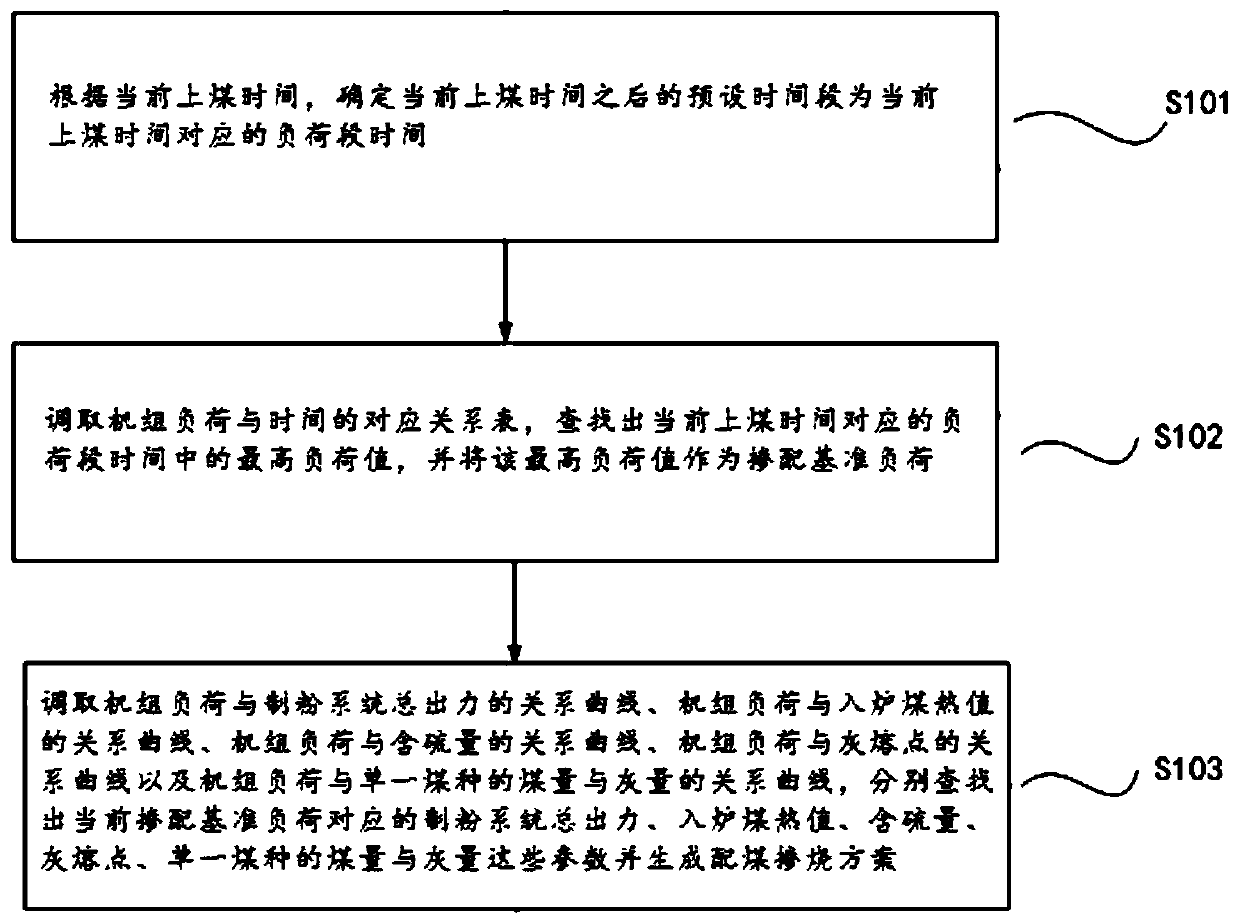

[0025] Such as figure 1 As shown, this embodiment provides a method for generating a coal blending and blending scheme for a coal-fired boiler in the load section, which includes:

[0026] S101: According to the current coal loading time, determine that the preset time period after the current coal loading time is the load segment time corresponding to the current coal loading time.

[0027] In this embodiment, the fuel is loaded with coal four times a day, because the coal in the raw coal bunker is not burned out, and according to the coal consumption, the load segment corresponding to each load of coal is the load segment of the last 6-12 hours.

[0028] S102: Retrieve the corresponding relationship table between unit load and time, find out the highest load value in the load period corresponding to the current coal loading time, and use the highest load value as the blending reference load;

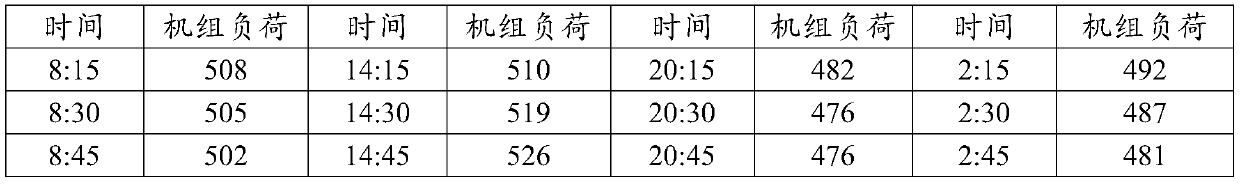

[0029] In the specific implementation, the establishment process of the correspon...

Embodiment 2

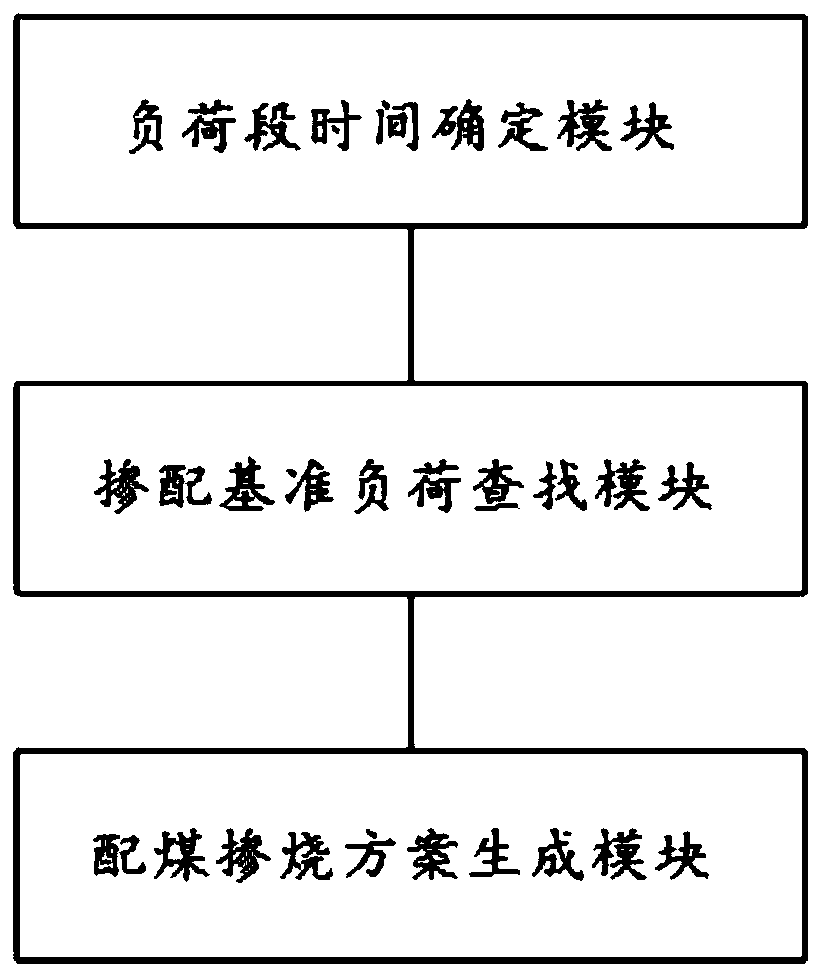

[0060] Such as figure 2 As shown, this embodiment provides a system for generating a coal blending and blending scheme for a coal-fired boiler in the load section, which includes:

[0061](1) Load segment time determination module, which is used to determine the preset time period after the current coal loading time as the load segment time corresponding to the current coal loading time according to the current coal loading time;

[0062] In this embodiment, the fuel is loaded with coal four times a day, because the coal in the raw coal bunker is not burned out, and according to the coal consumption, the load segment corresponding to each load of coal is the load segment of the last 6-12 hours.

[0063] (2) Blending reference load search module, which is used to retrieve the corresponding relationship table between unit load and time, find out the highest load value in the load period corresponding to the current coal loading time, and use the highest load value as the blendi...

Embodiment 3

[0093] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following figure 1 The steps in the method for generating the coal blending and blending scheme of the coal-fired boiler in the load section are shown.

[0094] In this embodiment, according to the current coal loading time, the preset time period after the current coal loading time is determined as the load segment time corresponding to the current coal loading time; The highest load value in the load period, and use the highest load value as the blending base load; finally, based on the blending base load, find out the total output of the pulverizing system, the calorific value of the furnace coal, and the sulfur content corresponding to the current blending base load. coal content, ash melting point, coal content and ash content of a single coal type, and generate coal blending and blending schemes. By blending the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com