Preparation method for mixed desulfurizing agent for circulating fluidized bed boiler

A circulating fluidized bed and desulfurizer technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low utilization rate of limestone powder, increase the burden of bag filter, and increase the wear and tear of tail equipment, etc. Achieve the effect of high utilization rate of desulfurizer, convenient operation and maintenance of equipment, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions therein are used as illustrations in essence, rather than limiting the present invention .

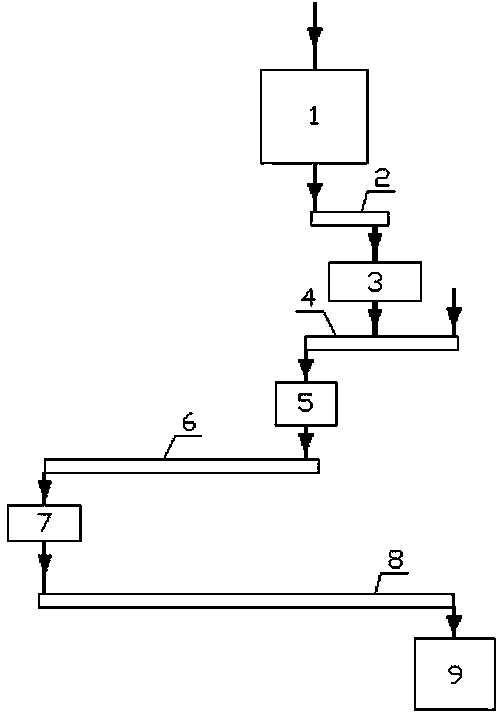

[0020] Such as figure 1 Shown, a kind of mixed desulfurizer preparation method for circulating fluidized bed boiler, its specific process steps are as follows:

[0021] ①The limestone fine powder material with a particle size of less than 0.3mm is transported to the limestone powder bin 1 through the compressed air pipeline;

[0022] ②Through the pipeline, the limestone fine powder material is initially stirred by the star wheel feeder 2 and the differential turbine 3, and then falls onto the coal slime conveyor belt 4;

[0023] ③ Add coal slime wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com