Raw coal bin system and operation method adapting to flexible blending of fuel of coal-fired boiler

A technology for coal-fired boilers and raw coal bunkers, applied in the field of raw coal bunker systems, can solve problems such as the unrealistic operation mode of changing mills, and achieve the effects of reducing fuel costs, improving power generation efficiency, and improving stable combustion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

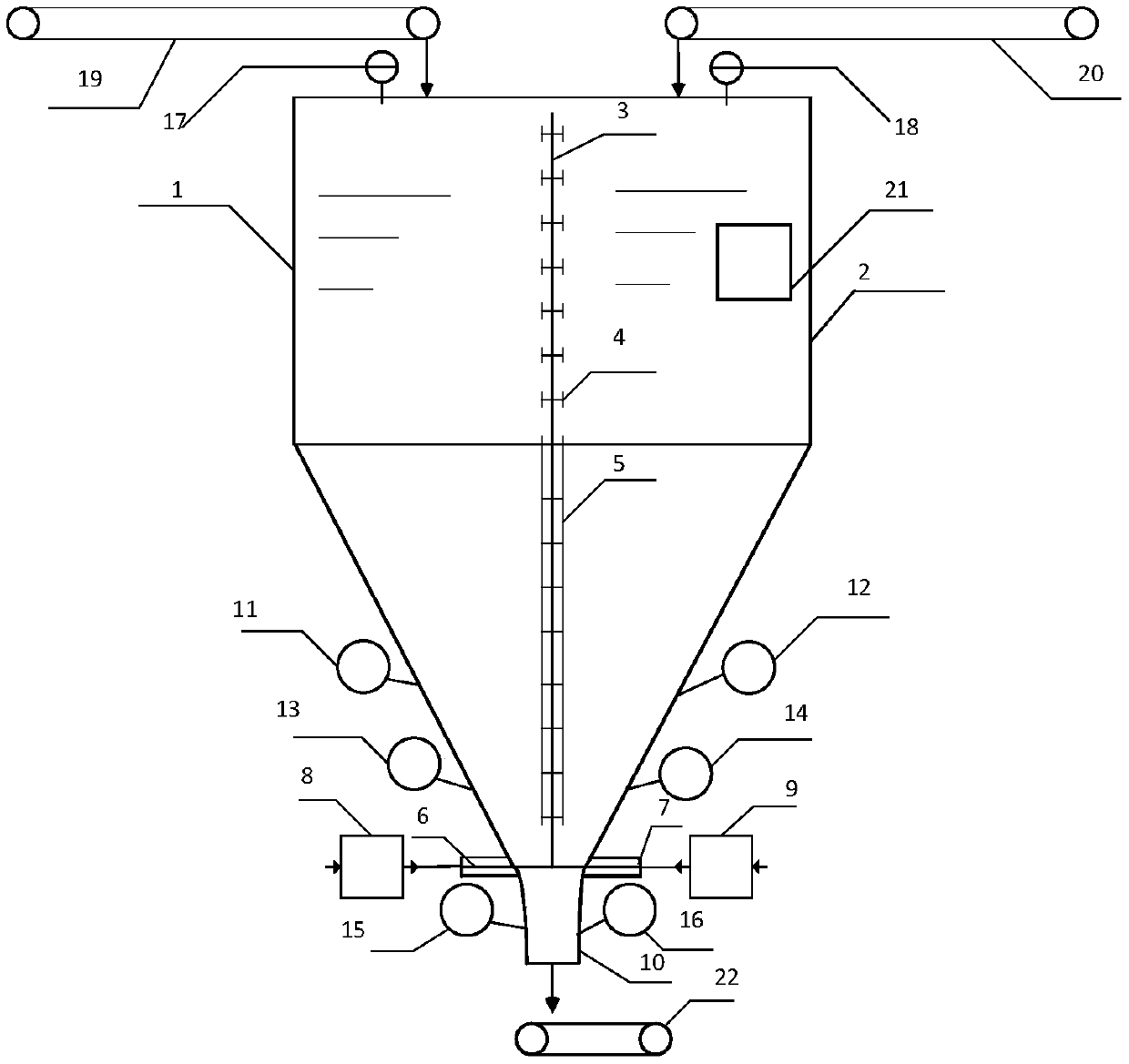

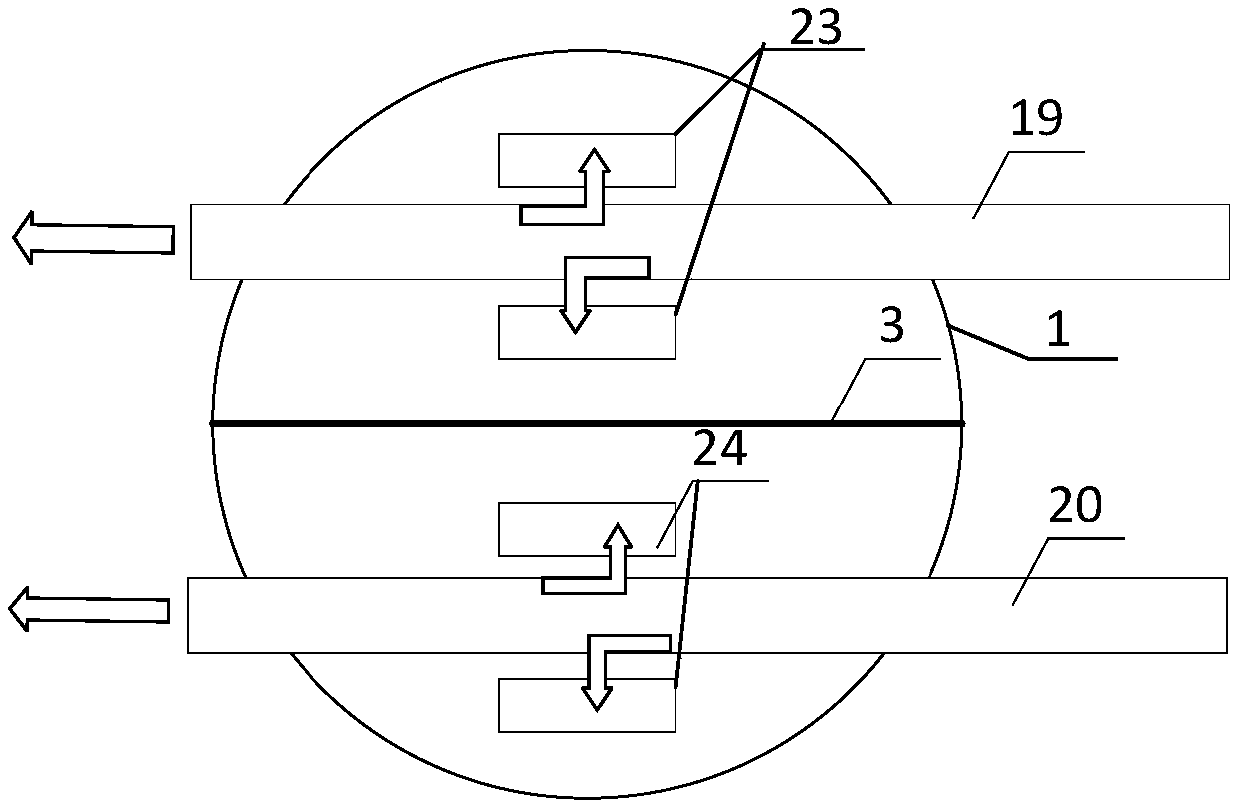

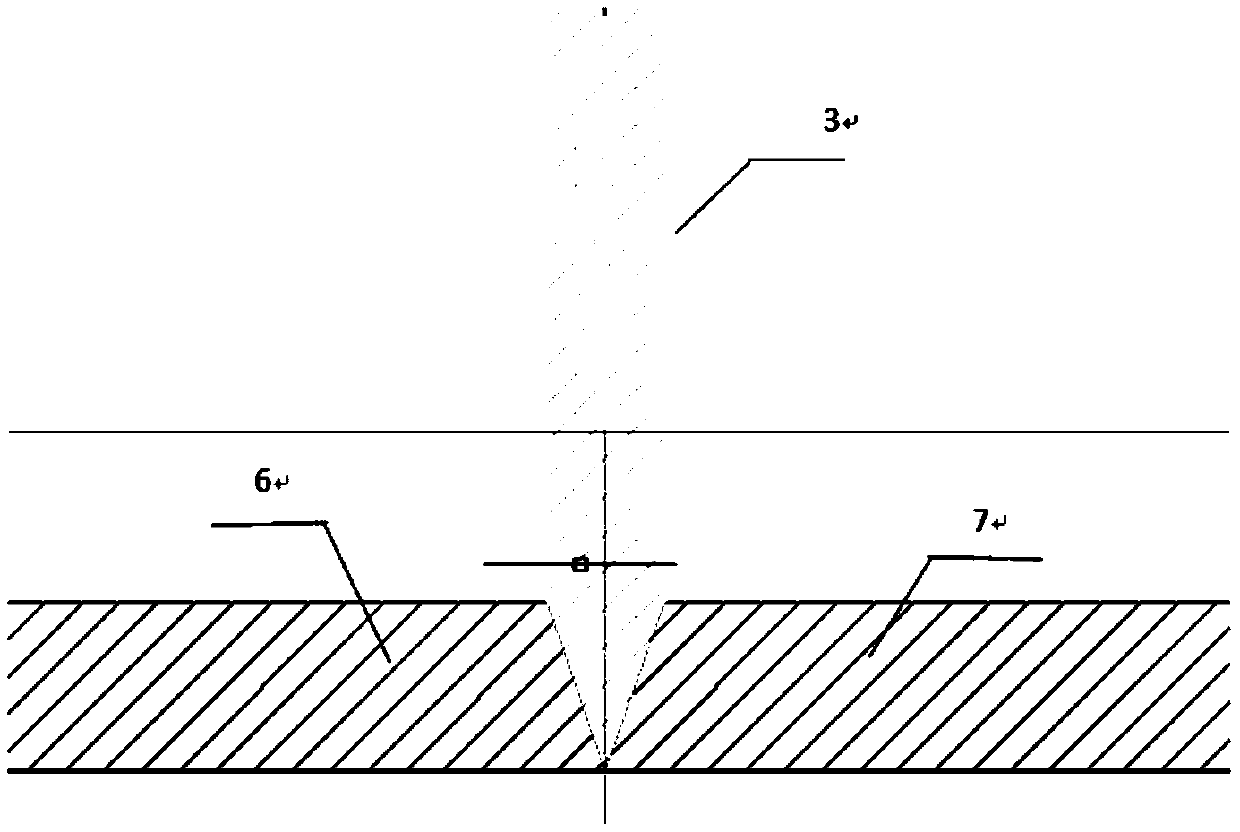

[0031] Such as Figure 1 to Figure 4As shown, the present invention provides a raw coal bunker system suitable for flexible fuel blending of coal-fired boilers, including a left coal bunker 1, a right coal bunker 2, a wear-resistant intermediate partition 3, H-shaped steel 4, and a stainless steel liner 5. Left hydraulic gate valve 6, right hydraulic gate valve 7, left hydraulic station 8, right hydraulic station 9, hyperbolic coal drop port 10, first to sixth air cannons 11-16, left Coal bunker guided wave radar level gauge 17, right coal bunker guided wave radar level gauge 18, left coal conveyor belt 19, right coal conveyor belt 20, manhole door 21, coal feeder 22, left coal drop Port 23 and right side coal drop port 24.

[0032] The wear-resistant intermediate partition plate 3 used to divide the coal bunker is welded in the middle of the raw coal bunke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com