Raw coal bunker structure of direct-fired pulverizing system and deep peak regulation method

A technology of pulverizing system and raw coal bunker, which is applied in the combustion method, combustion control, and fuel supply adjustment, can solve the problems of flexible blending of coal quality that cannot be fed into the furnace, improve the flexibility of peak regulation and reduce stable combustion. load, the effect of reducing production and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

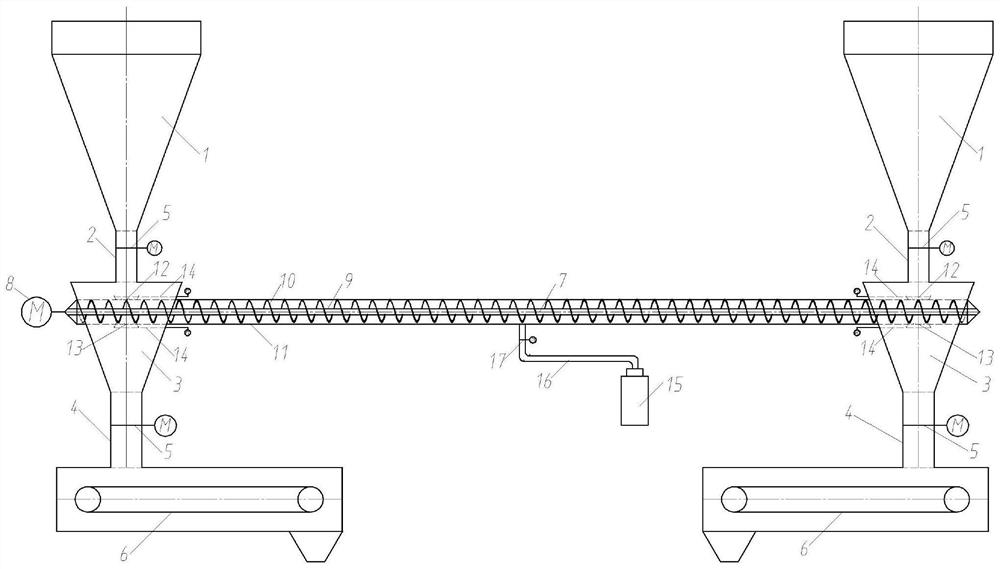

[0022] see figure 1 , The raw coal bunker structure of the direct-blown pulverizing system of the present invention includes several groups of raw coal bunker units, and different raw coal bunker units store coal types with different grades of volatile matter and calorific value. The raw coal bunker unit includes a storage bin 1, the storage bin 1 is connected to the coal feeder 6 through the deployment bin 3, the storage bin 1 and the deployment bin 3 are connected through the lower coal pipe 2, the deployment bin 3 and the coal feeder 6 are connected through The pipe 4 is connected, and the lower coal pipe 2 and the coal falling pipe 4 are all provided with a coal gate 5, and the coal gate 5 is driven by an electric motor. Different raw coal bunker units are connected to the deployment bin 3 through the auger device 7, which is arranged hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com