Household waste incinerator for co-processing dry sludge and disposal method adopting household waste incinerator

A technology for domestic waste incineration and sludge drying, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of limited amount of sludge mixing and sticking, so as to reduce the incineration time and ensure burnout. rate, the effect of increasing the mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The domestic waste incinerator and its treatment method for co-processing dried sludge described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples of the description, but the explanation and illustration do not necessarily define the technical solution of the present invention. constitute an improper limitation.

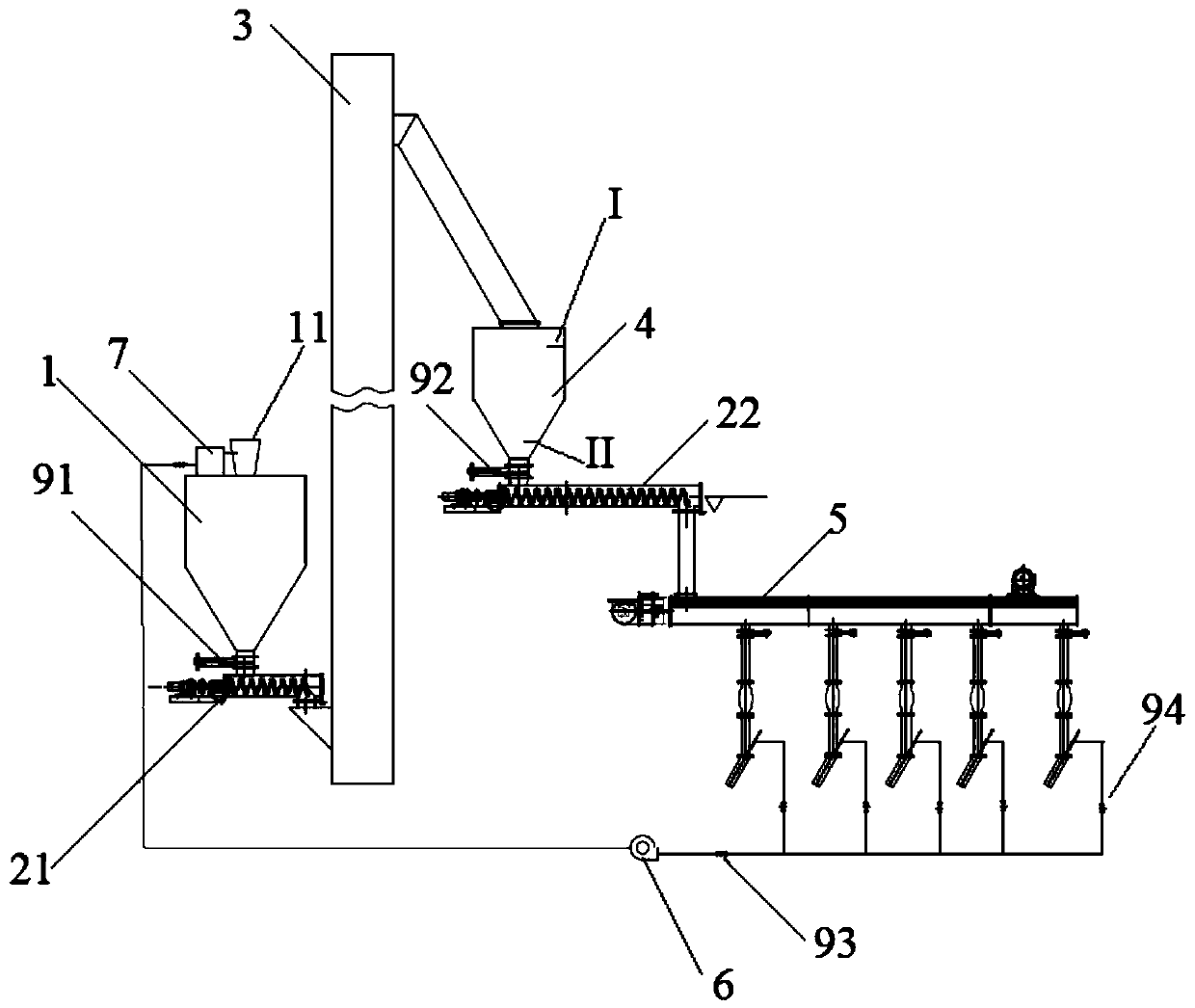

[0042] figure 1 It is a schematic diagram of the system structure in some embodiments of the domestic waste incinerator for co-processing dried sludge according to the present invention.

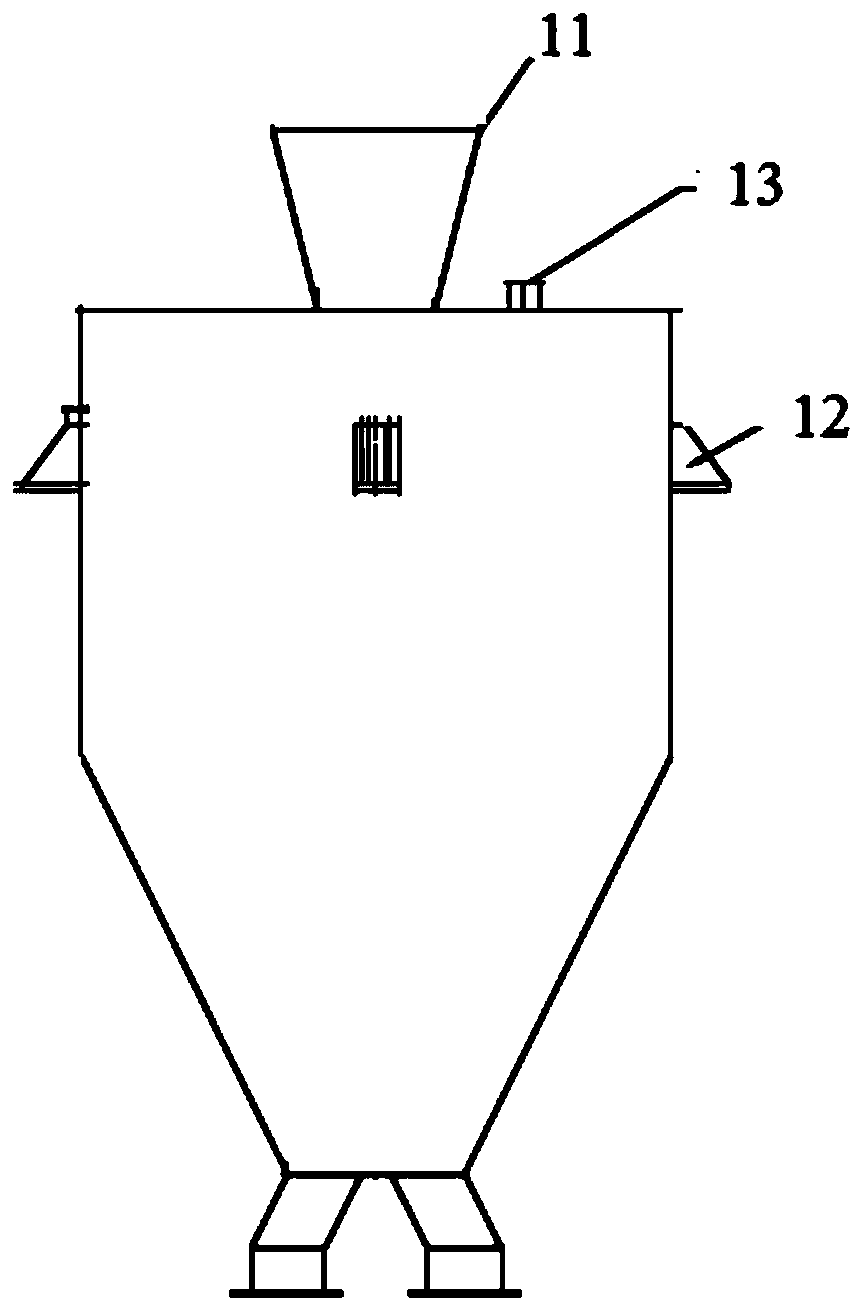

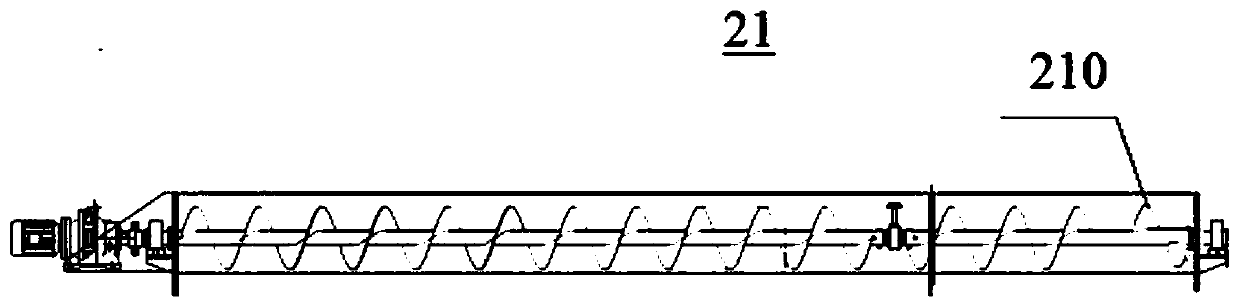

[0043] Such as figure 1 shown, and refer to the Figure 6 , in this embodiment, the domestic waste incinerator for co-processing dried sludge includes an incinerator 100 and a dried sludge treatment system attached to the incinerator 100, wherein the dried sludge treatment system and the incinerator 100 connected, the dried sludge treatment system puts sludge particles into the incinerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com