Inferior gasoline upgrading method

A low-quality gasoline and upgrading technology, applied in the direction of naphtha catalytic reforming, etc., can solve the problems of limited development and low yield of straight-run gasoline, and achieve the effects of prolonging the operation cycle, increasing the yield, and increasing the blending ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Catalysts used in the present invention are prepared.

[0032] (1) Prepare the carrier: get 130 grams of HZSM-5 zeolite powder (produced by Shanghai Huaheng Catalyst Factory) with a silica / alumina molar ratio of 56, and 90 grams of α-alumina monohydrate powder (produced by German Condea Company), mix Evenly, add a solution made of 2 ml of 1:1 nitric acid and 50 ml of deionized water, knead into a dough, extrude into strips with a diameter of 2 mm and a length of 2 to 4 mm in an extruder, and dry at 110 ° C for 10 hours. Baking at 550°C for 4 hours.

[0033] (2) Introduce active components: Take 100 grams of the above-mentioned carrier, use 100 milliliters containing 2.28 grams of mixed rare earth chloride (produced by Inner Mongolia Baotou Rare Earth Industry Company, wherein 31% by mass of lanthanum oxide, 51% by mass of cerium oxide, 14% by mass praseodymium oxide and 4% by mass neodymium oxide) in an aqueous solution at 70°C for 2 hours, dried at 110°C for 10 hours,...

example 2

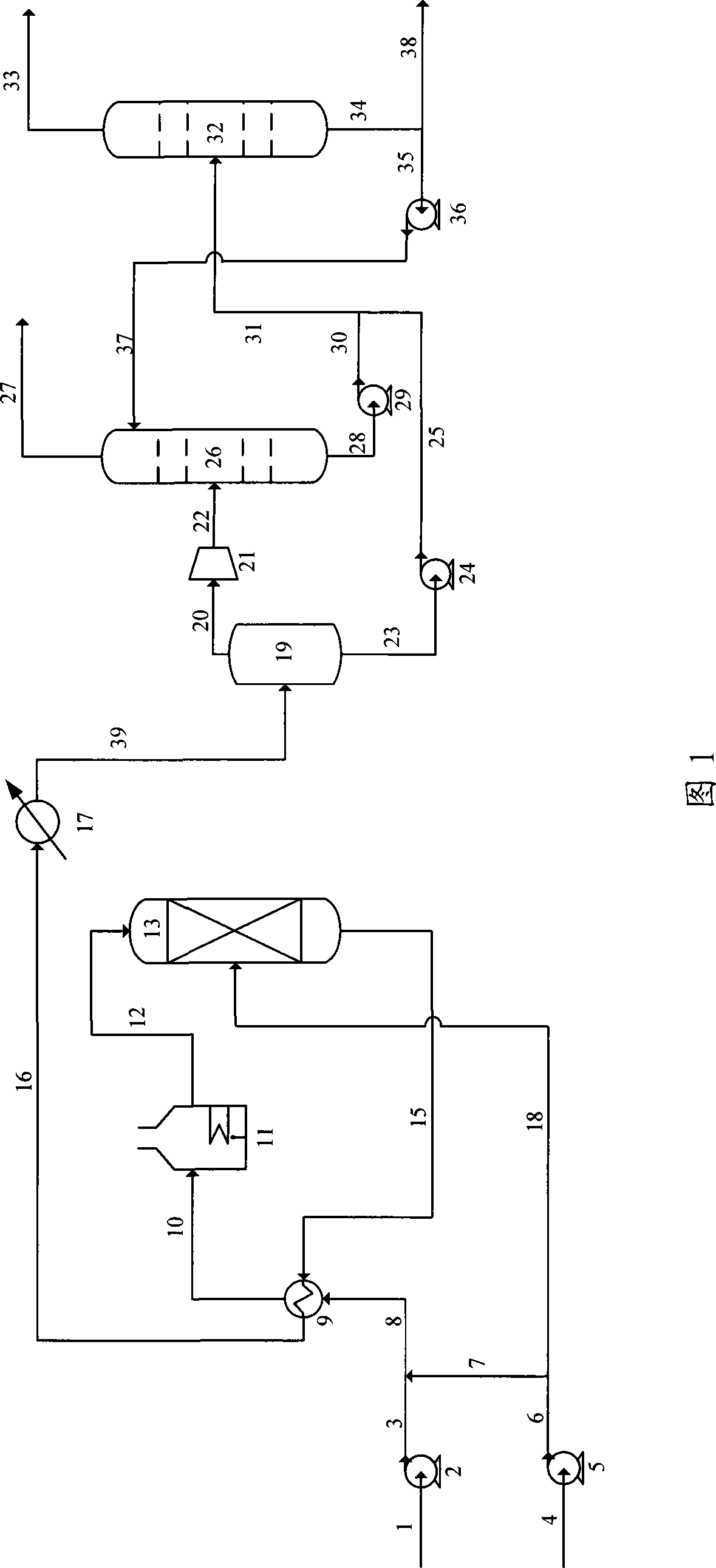

[0037] On the 100mL single-tube fixed-bed test device, fill 100mL catalyst A in a reactor, with the carbon four fraction shown in 20 mass % table 1 and the hydrocoking gasoline shown in 80 mass % table 2 as raw material, at 0.3 MPa, mass space velocity 0.4hr -1 , Control the octane number of gasoline products to 86, and carry out the non-hydrogen modification reaction under the conditions of 330-450°C. Among them, the C4 fraction is divided into two streams and enters the reactor according to the method shown in Figure 1. The first stream enters the reactor from the top after being mixed with hydrocoking gasoline, and the second stream enters the reactor from the middle. The reaction results are shown in Table 3.

example 3

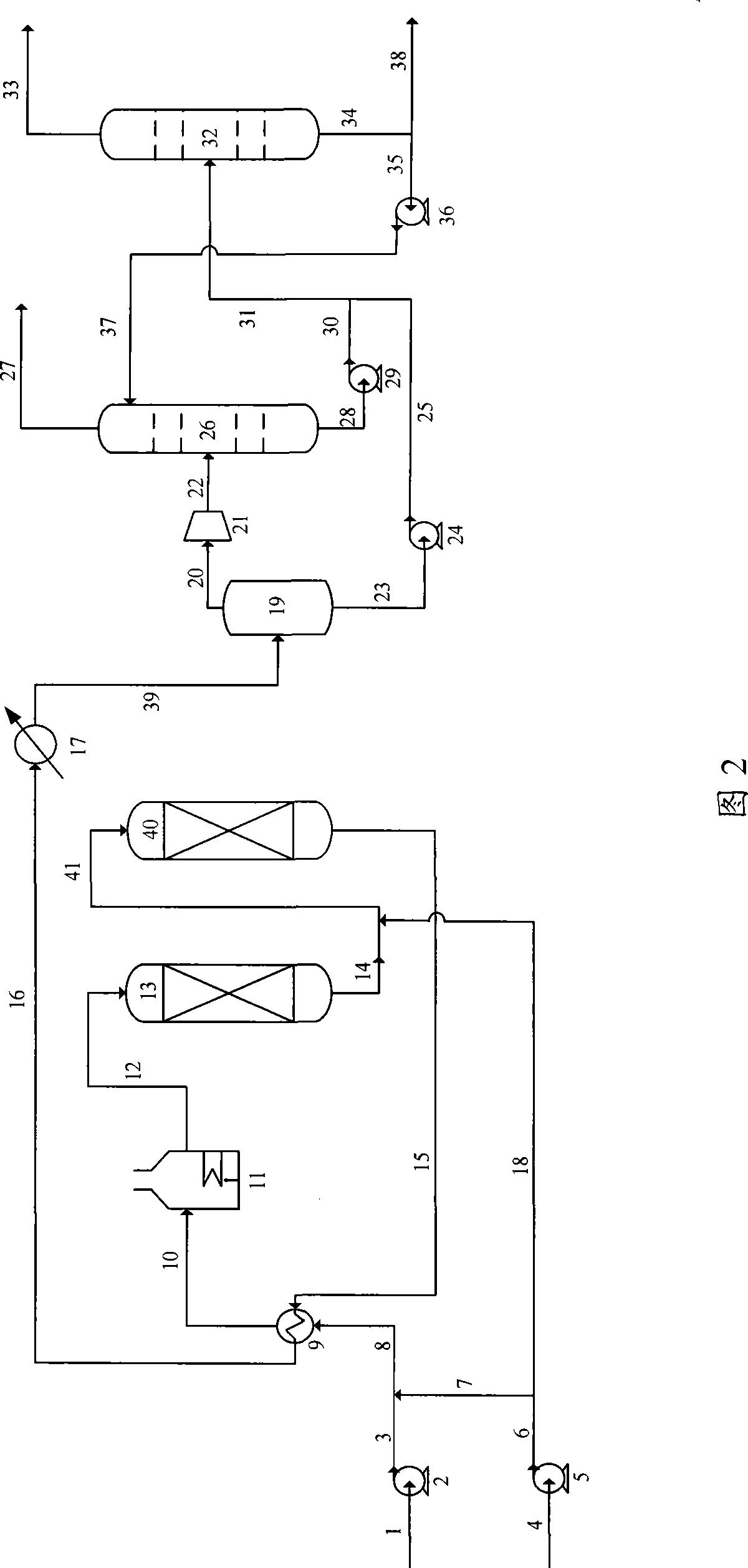

[0048] On the 100mL multi-tube fixed-bed test device, 100mL catalyst A was loaded in equal proportions in three series reactors, with 60% by mass of carbon four cuts and 40% by mass of hydrocoked gasoline as raw materials, at 0.3MPa, mass Airspeed 0.4hr -1 1. Control the gasoline product with an octane number of 88 and a reaction temperature of 330-450°C to carry out the non-hydrogen upgrading reaction, and divide the C4 fraction into three streams and enter the top of each reactor in equal proportions. The reaction results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com