Thermal power unit sliding pressure optimizing and regulating system and method

A technology for thermal power units and regulating systems, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as difficulty in sliding pressure curve, discount of optimization results, and reduction of energy storage level, and achieve optimal sliding pressure. The effect of operating pressure, improving load economy and reducing throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

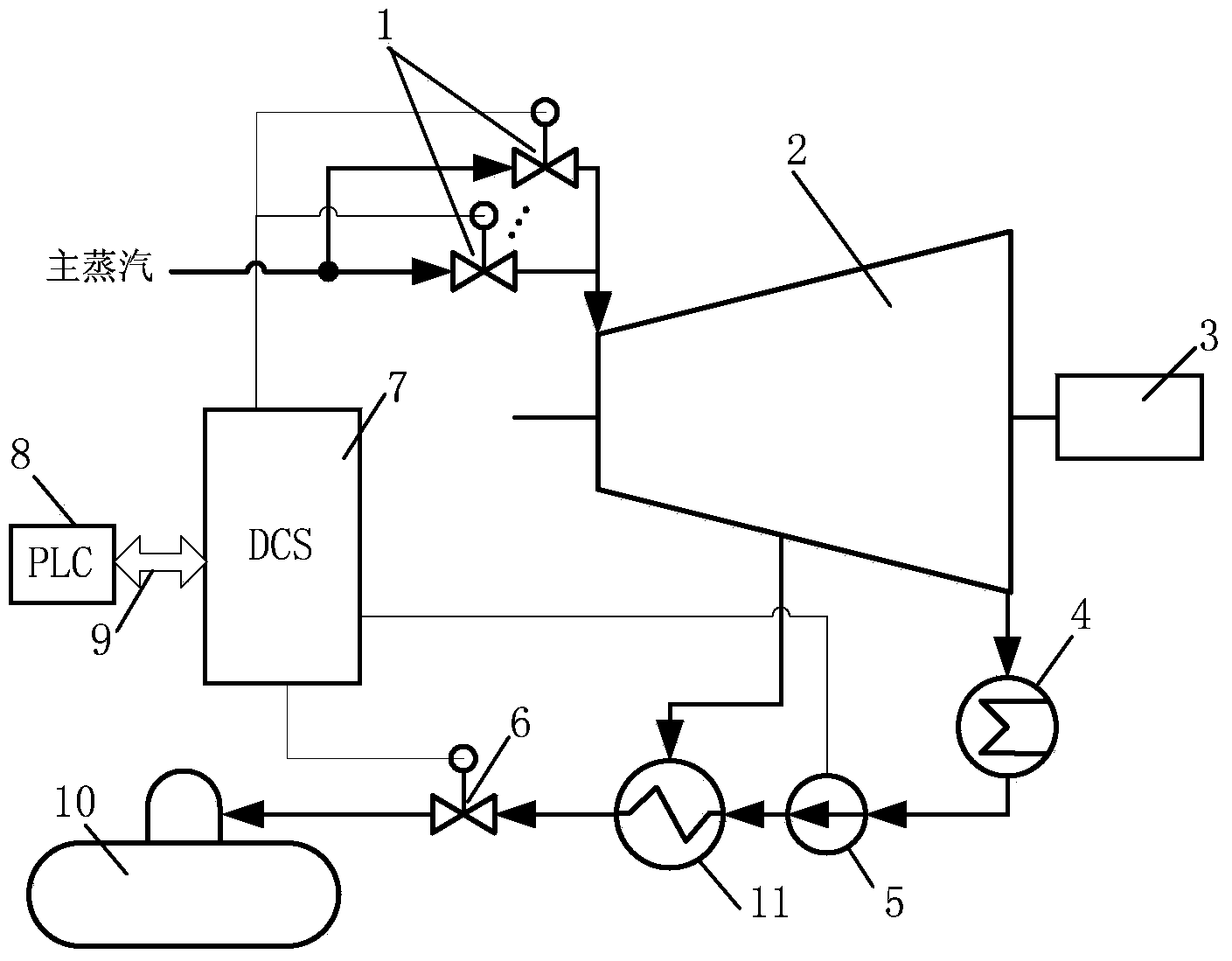

[0024] Such as figure 1As shown, the main steam from the boiler enters the steam turbine 2 through multiple steam turbine high-pressure regulating valves 1 to do work and drives the generator 3 to generate electric energy. The steam that has done work leaves the steam turbine 2 and enters the condenser 4 to condense into liquid condensate, which is sent to the deaerator 10 by the frequency conversion condensate pump 5 through multiple low-pressure heaters 11 and the deaerator water level regulating valve 6 . Part of the steam is extracted from the steam turbine 2, and the condensed water is heated in the low-pressure heater 11 to realize the heat recovery effect. The thermal power unit sliding pressure optimization adjustment system of the present invention includes a PLC control unit 8, a decentralized control system 7 connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com