Precomputation method of frequency conversion transformation working condition points of condensate pump for thermoelectric generating set

A technology for condensate pumps and generator sets, which is applied to machines/engines, pump control, mechanical equipment, etc., and can solve problems such as motor current exceeding the limit, uneconomical variable speed operation of condensate pumps, and reduced energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

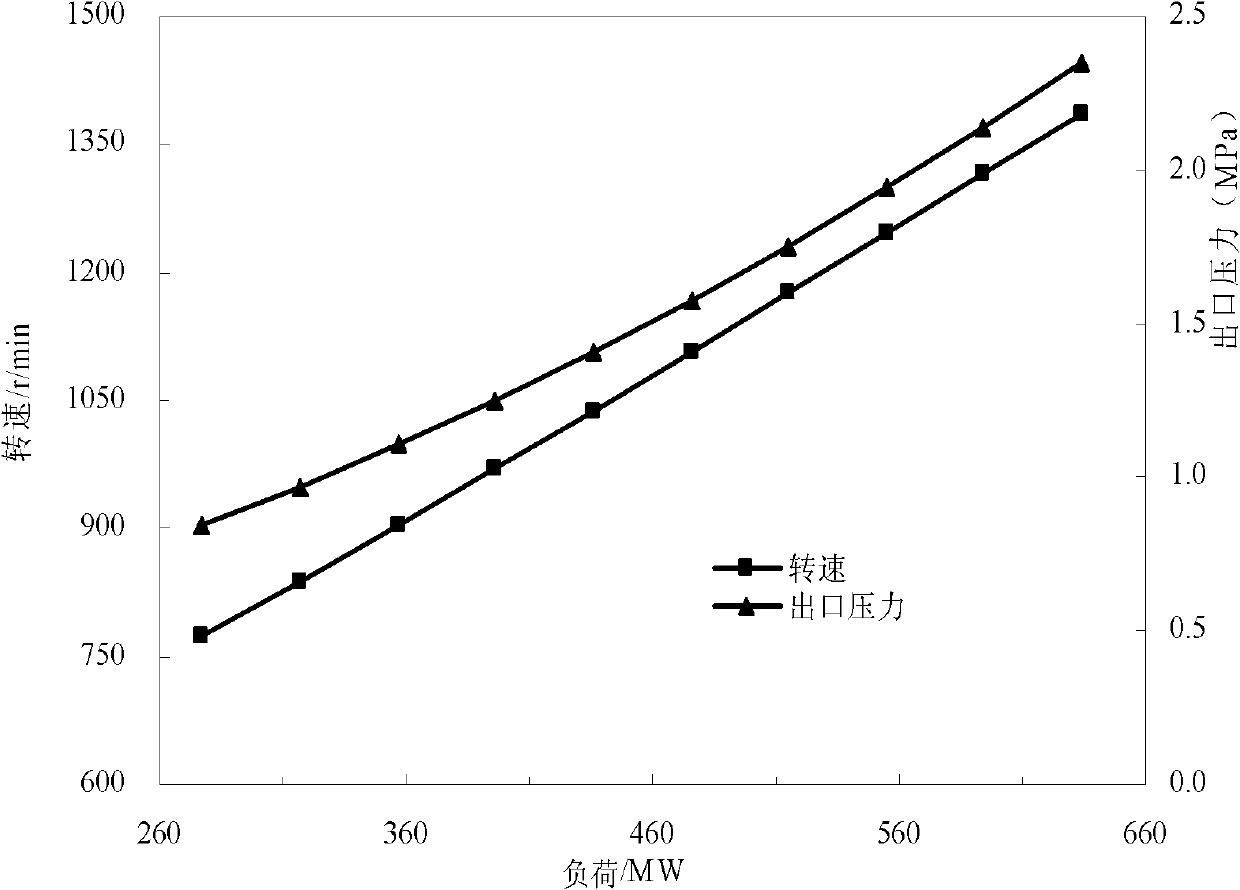

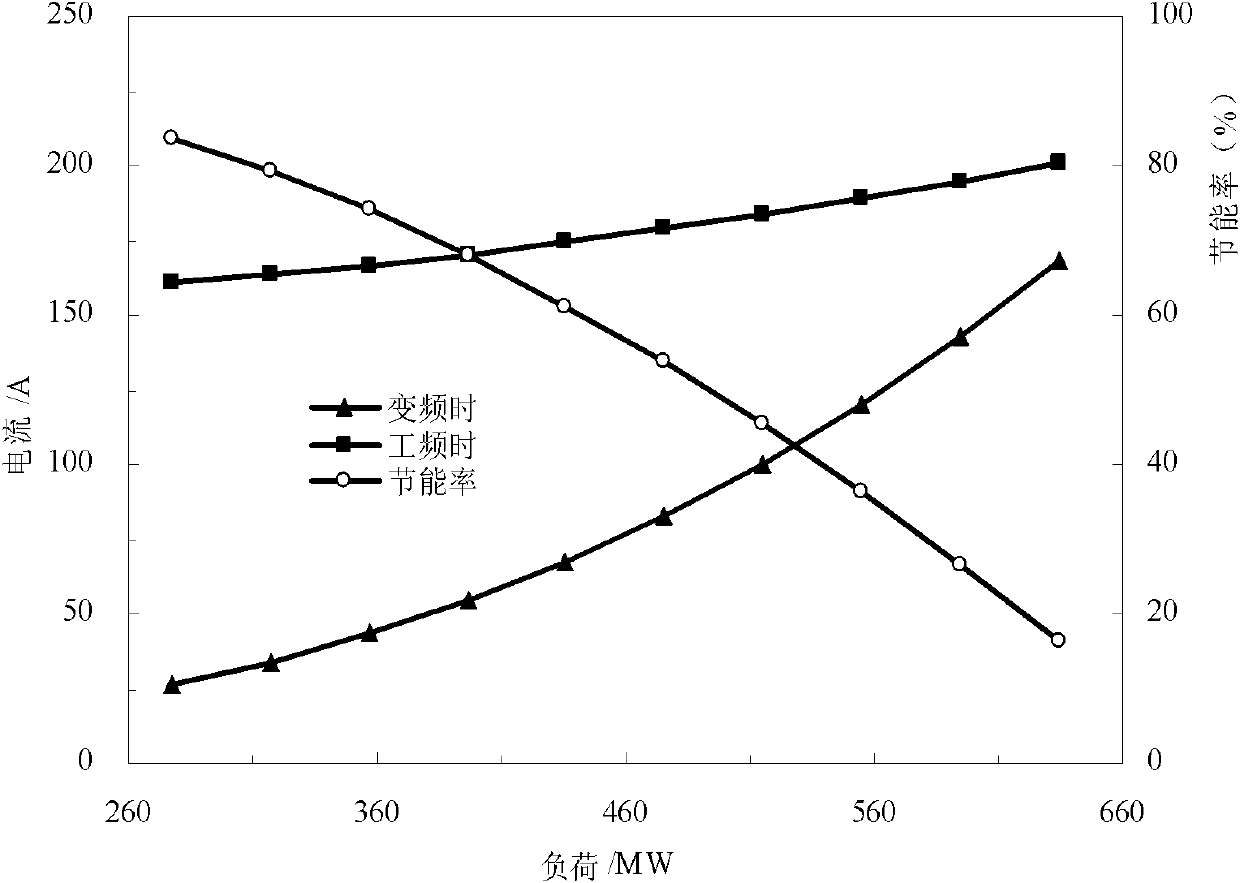

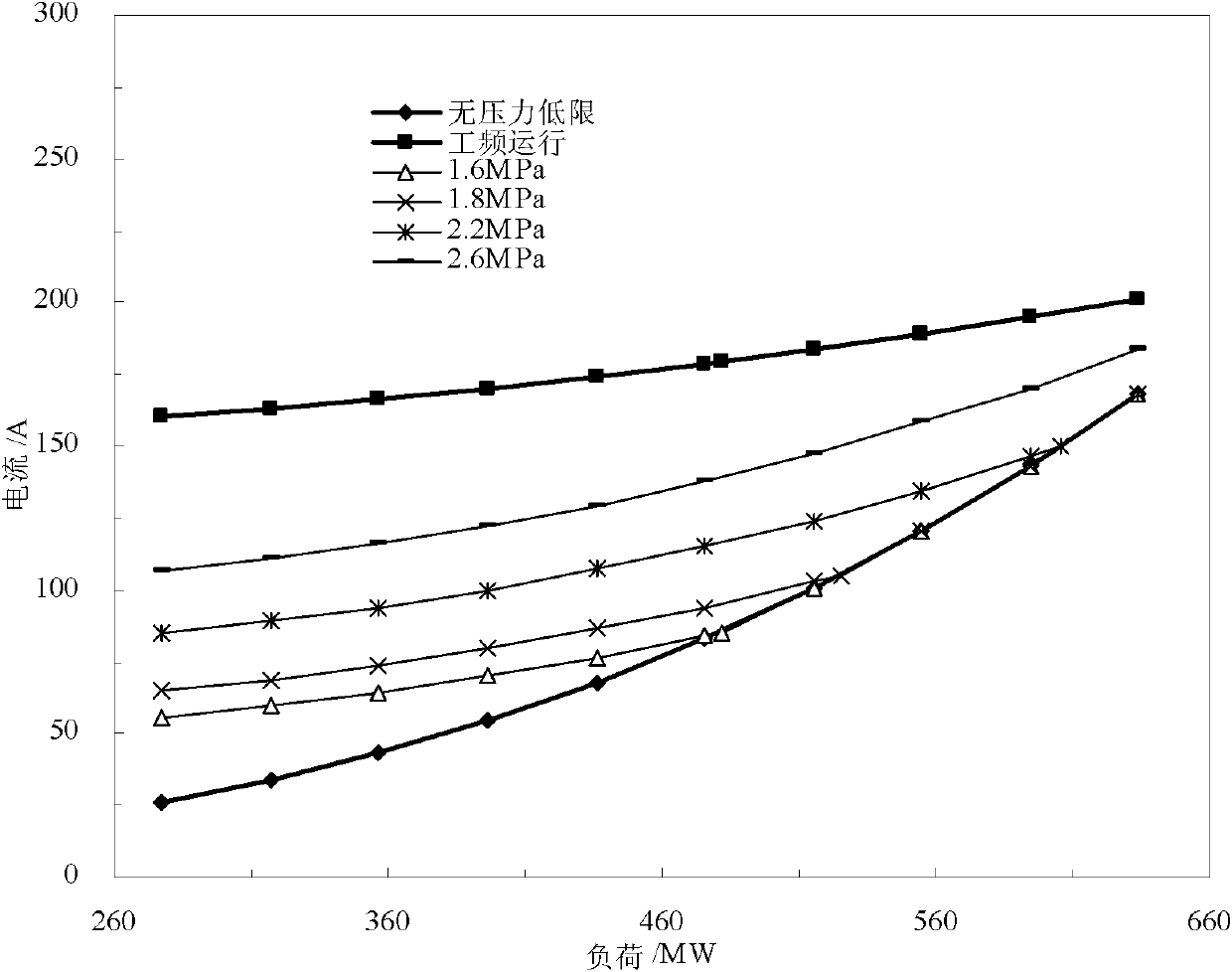

[0040] The rated speed of the condensate pump motor of a 600MW subcritical thermal power unit is 1490r / min, ΔH=0.3MPa, Q md =1511t / h, P cyd =0.6MPa, according to the test results under the power frequency state and the design data of the main and auxiliary regulating valves, ΔP can be calculated m =0.401MPa, ΔP n =1.262MPa, ΔP l =0.863MPa, thus formula (4) can be determined as: P 0 = 5.537 × 10 - 7 Q m 2 + 3.971 × 10 - 4 Q m + 0.3 .

[0041] In the case that the condensate user has no restrictions on the outlet pressure of the condensate pump, the relationship between the speed, outlet pressure and load of the condensate pump after it is changed to variable speed operation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com