Hollow anti-resonance optical fiber

An anti-resonance, optical fiber technology, applied in cladding fibers, light guides, optics, etc., can solve the problems of not having the complete bandgap characteristics of photonic crystal fibers, limiting application requirements, and narrow transmission bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

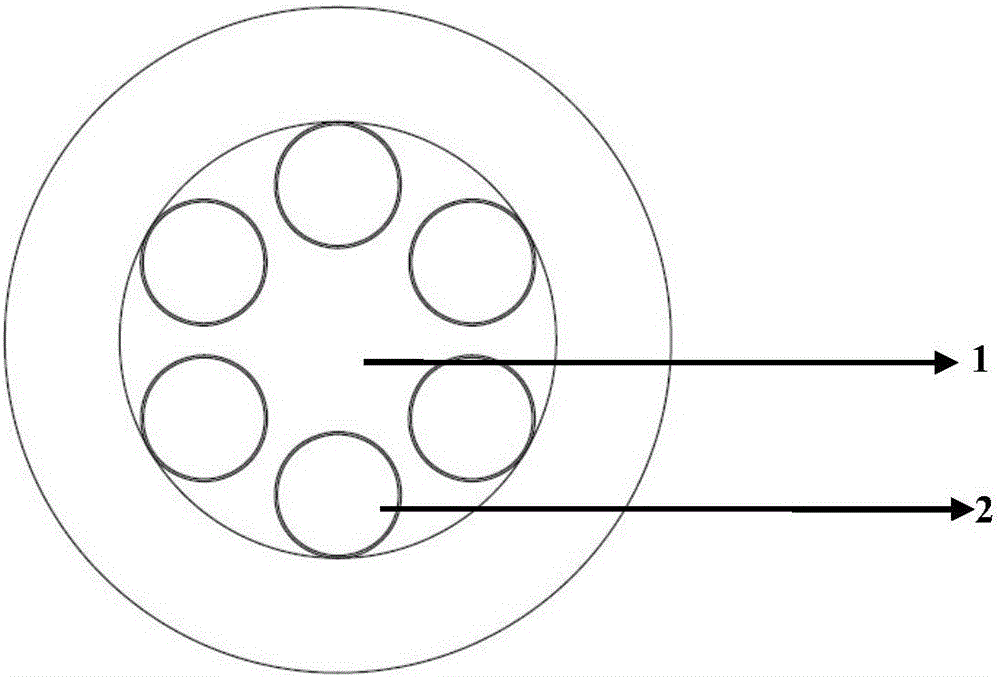

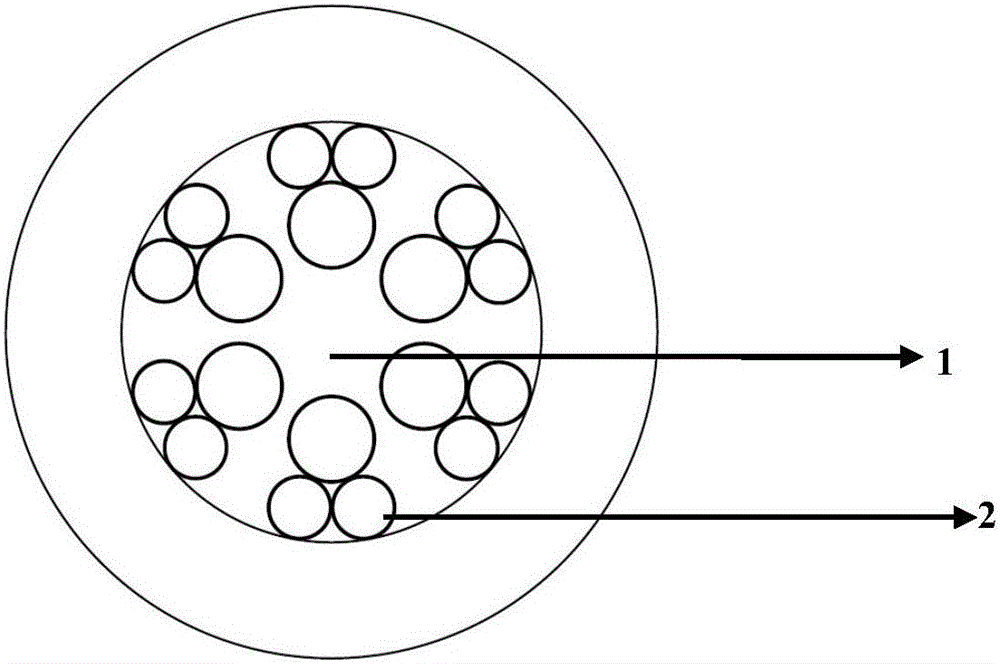

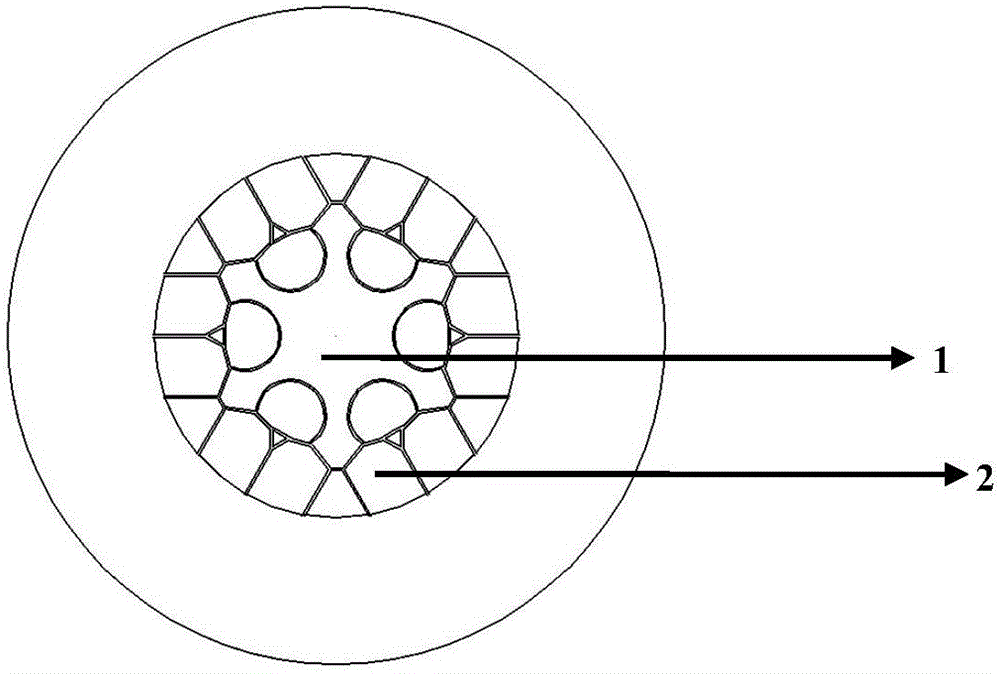

[0028] figure 1 , figure 2 with image 3 Schematic diagrams of end face structures of the first, second and third embodiments of the hollow-core anti-resonant optical fiber of the present invention are given. Their structures all include a core region (1) with a low refractive index and a cladding region with a high refractive index, and the cladding region with a high refractive index is jointly composed of an inner cladding region (2) and an outer cladding region. Among them, the low-refractive-index core area (1) is air; the inner cladding area (2) is formed by a plurality of microcapillaries, and the innermost (closest to the core) circle of microcapillaries is not in contact with each other and has no nodes. , has a negative curvature structure; the outer cladding region is formed by a solid material with a uniform distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com