Patents

Literature

112 results about "Micro capillary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

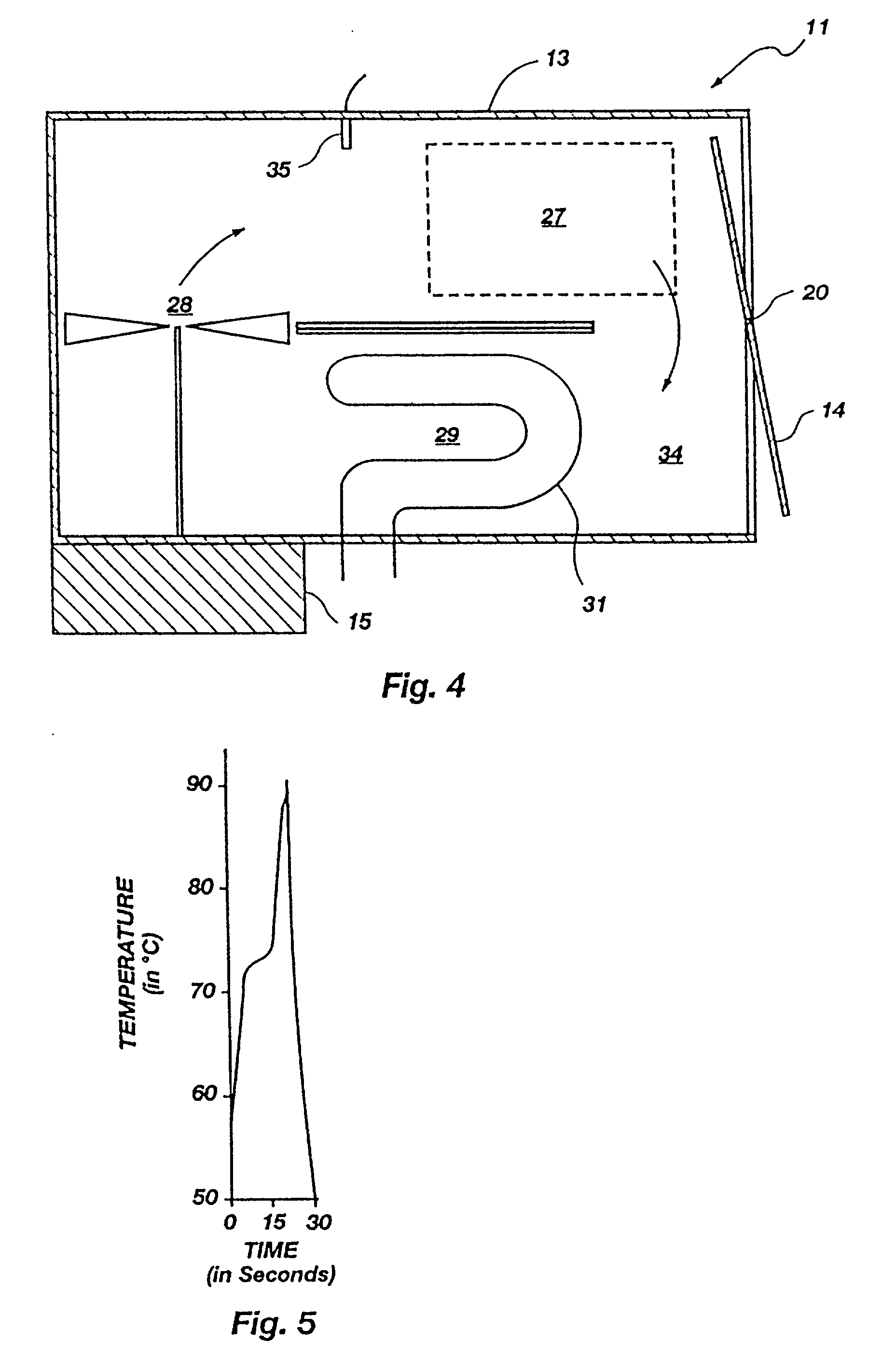

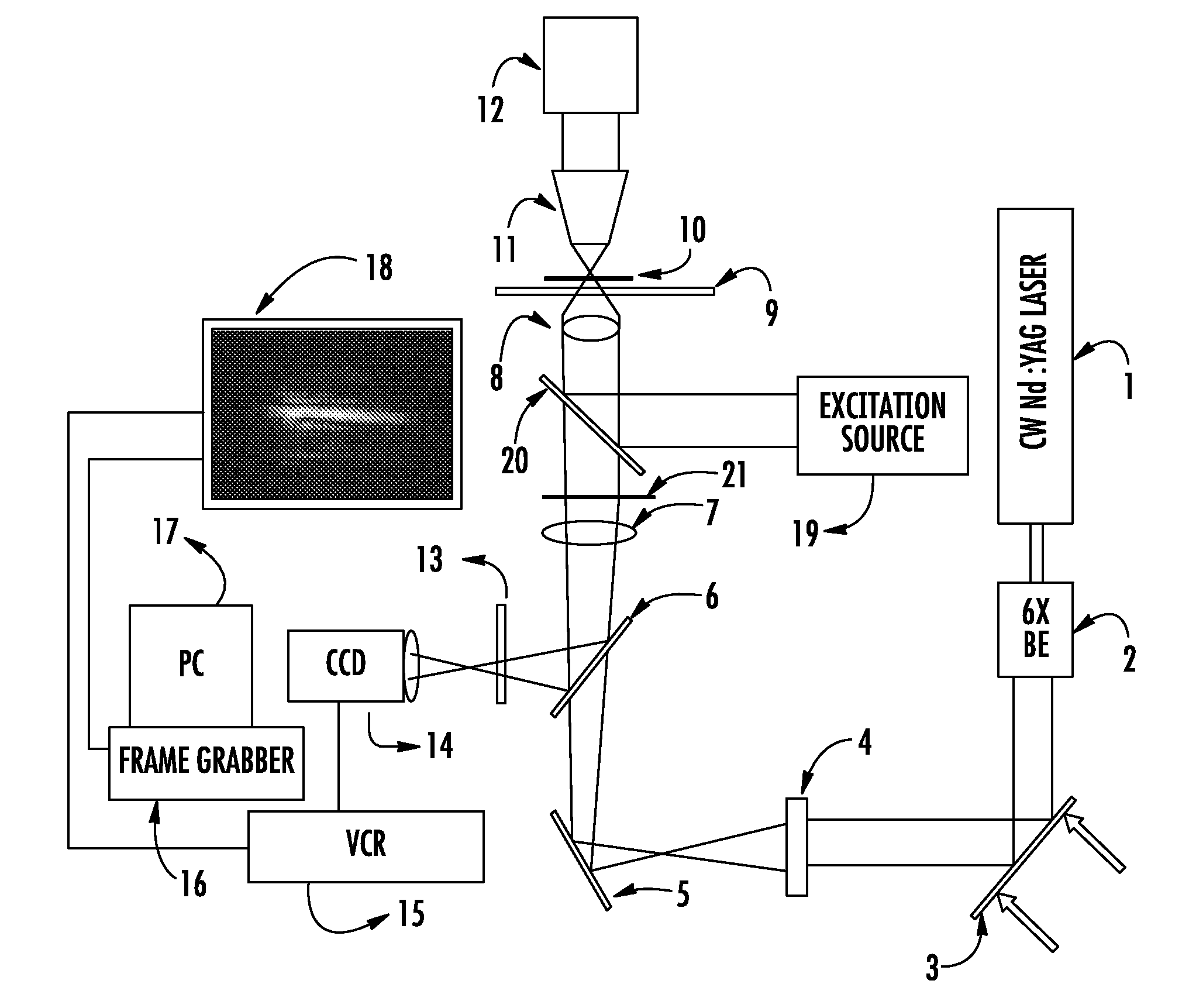

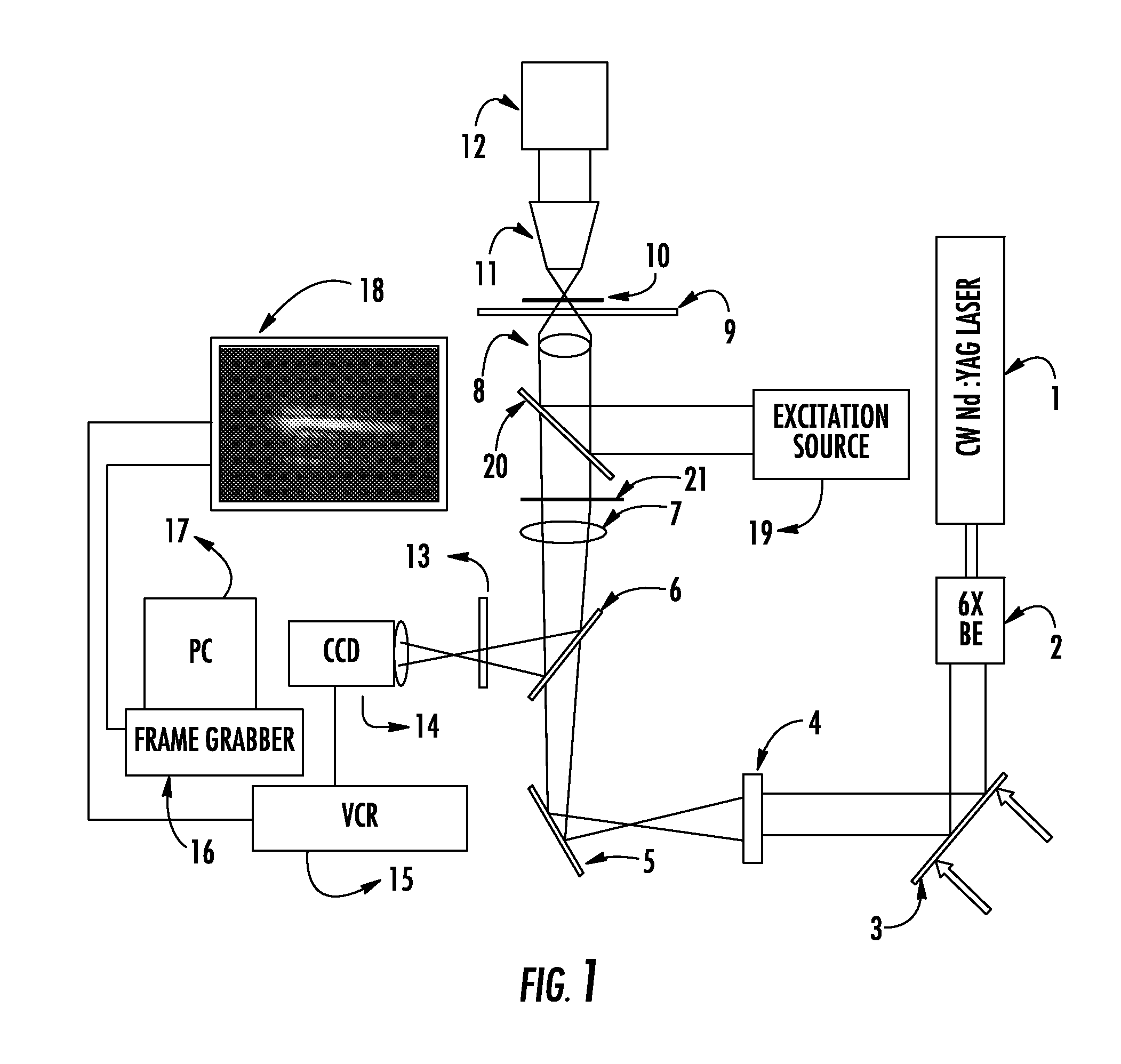

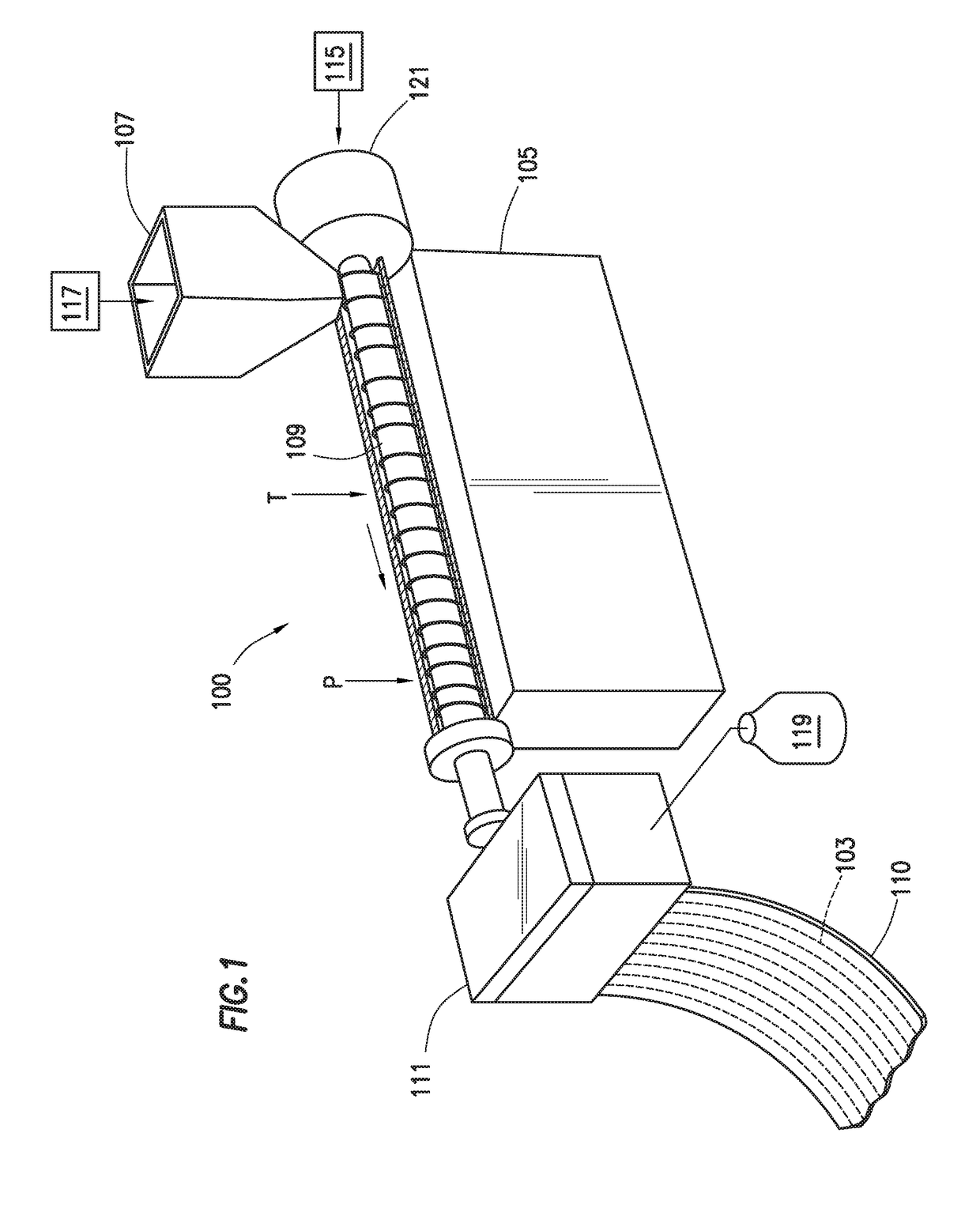

System and method for fluorescence monitoring

InactiveUS7081226B1Easy to controlHeating or cooling apparatusMicrobiological testing/measurementFluorescenceDna amplification

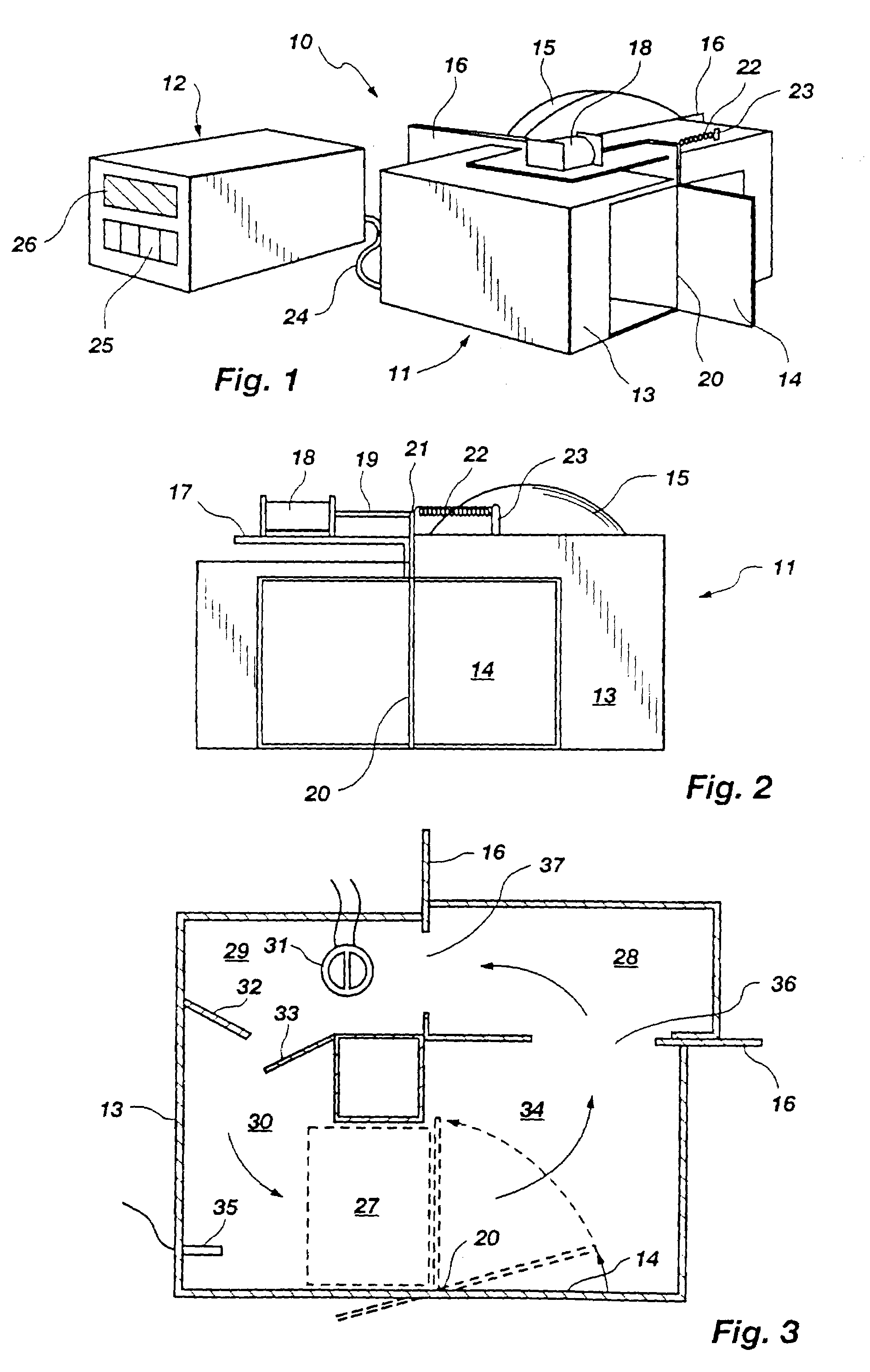

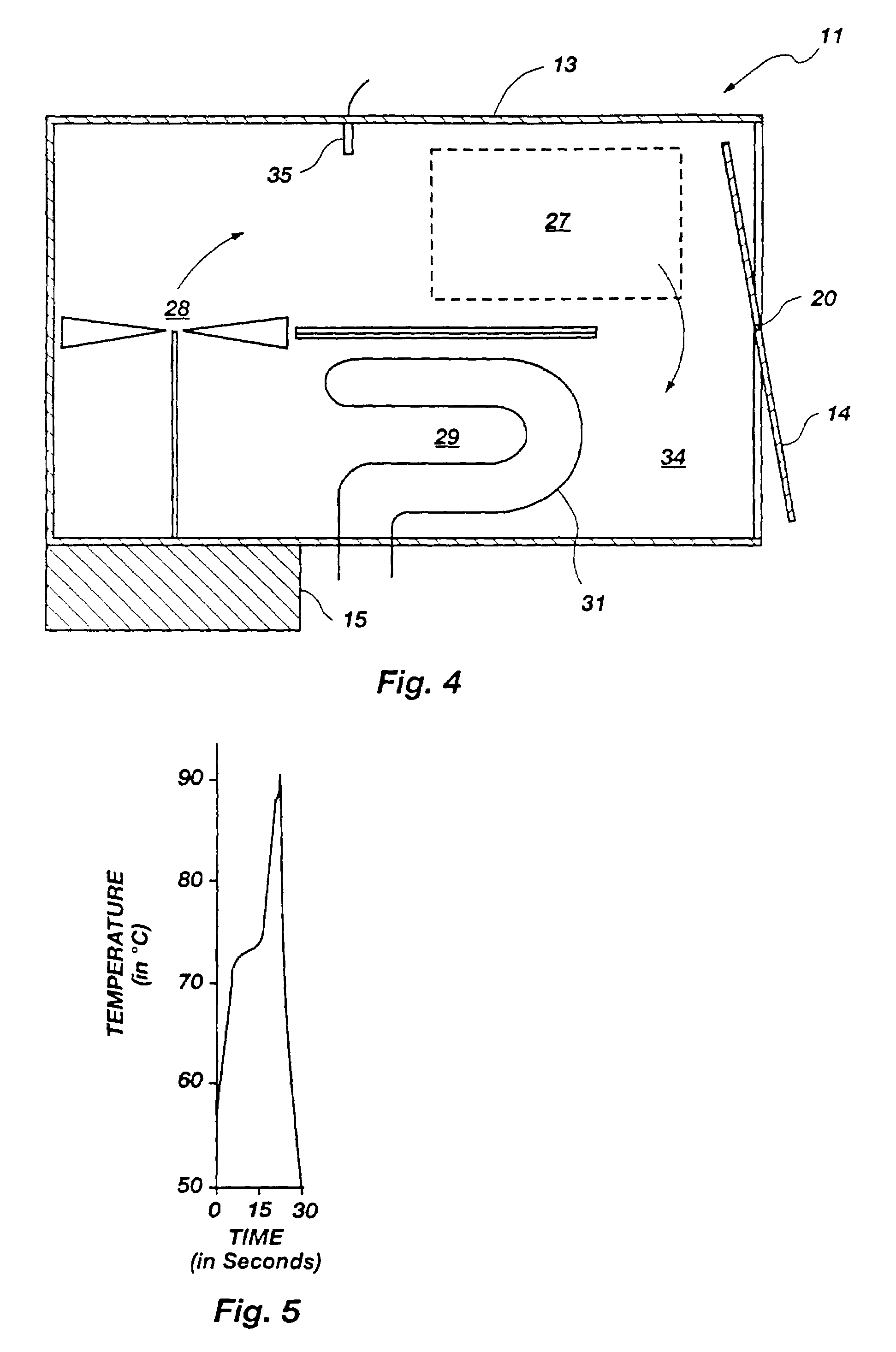

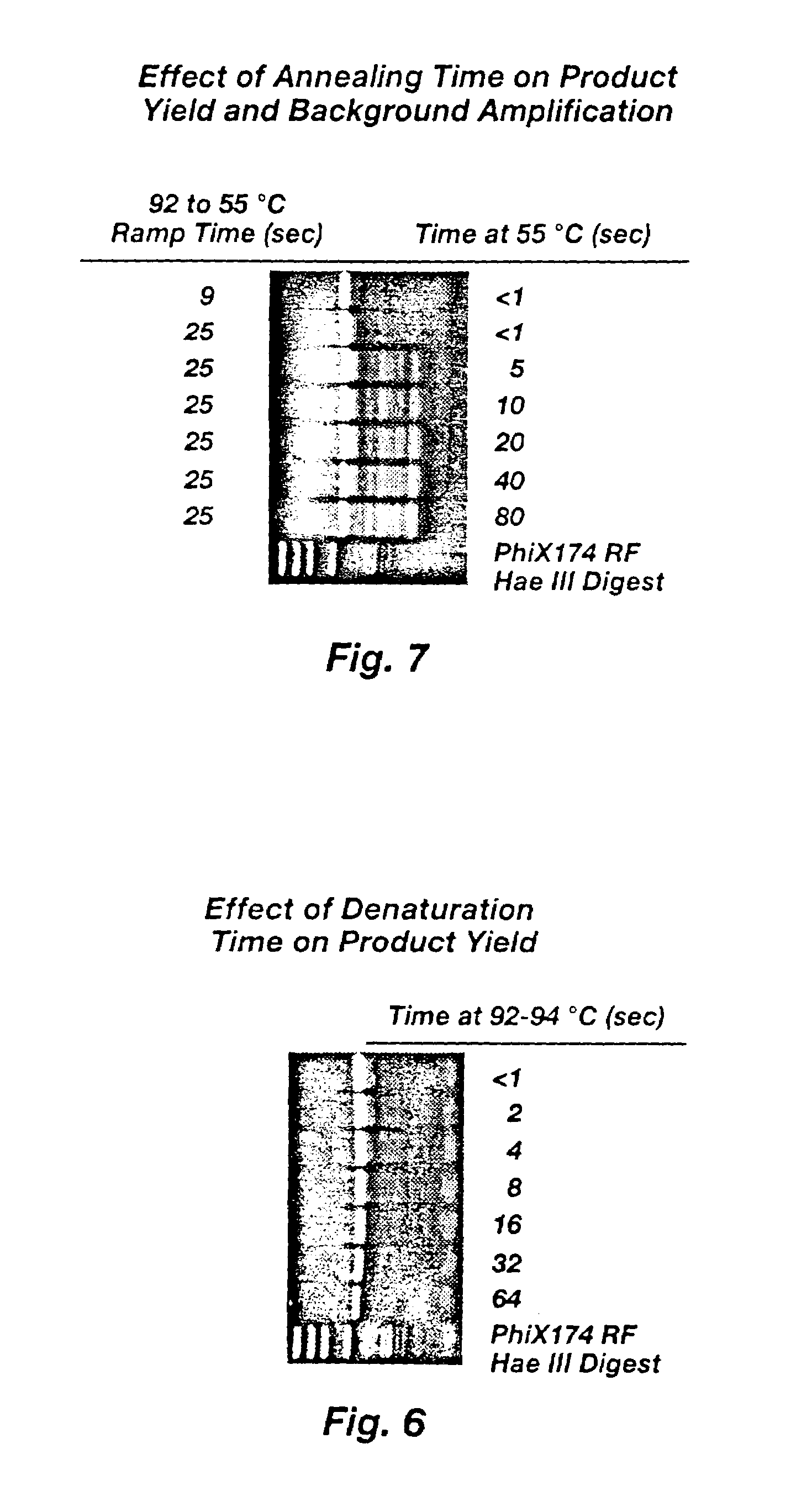

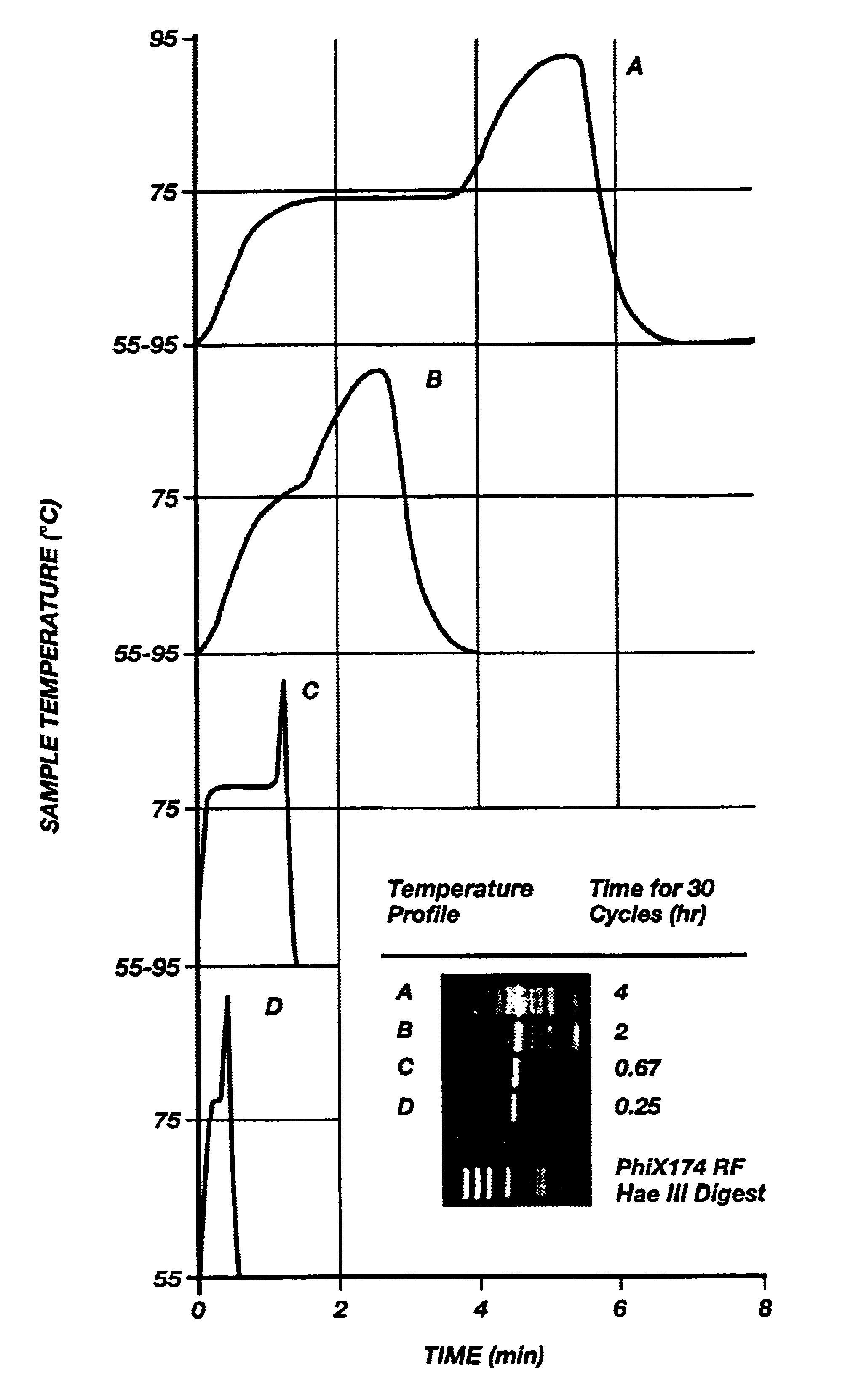

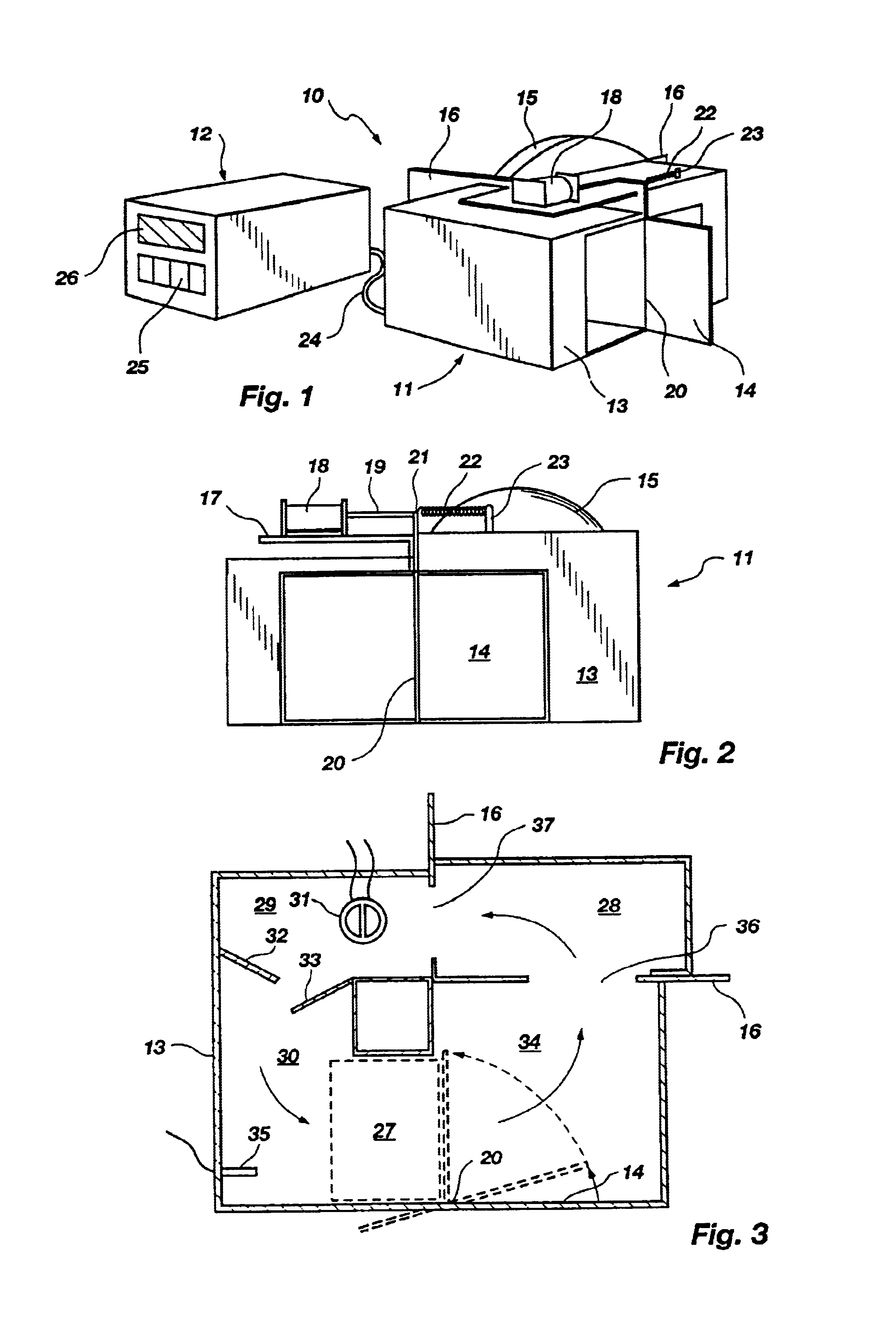

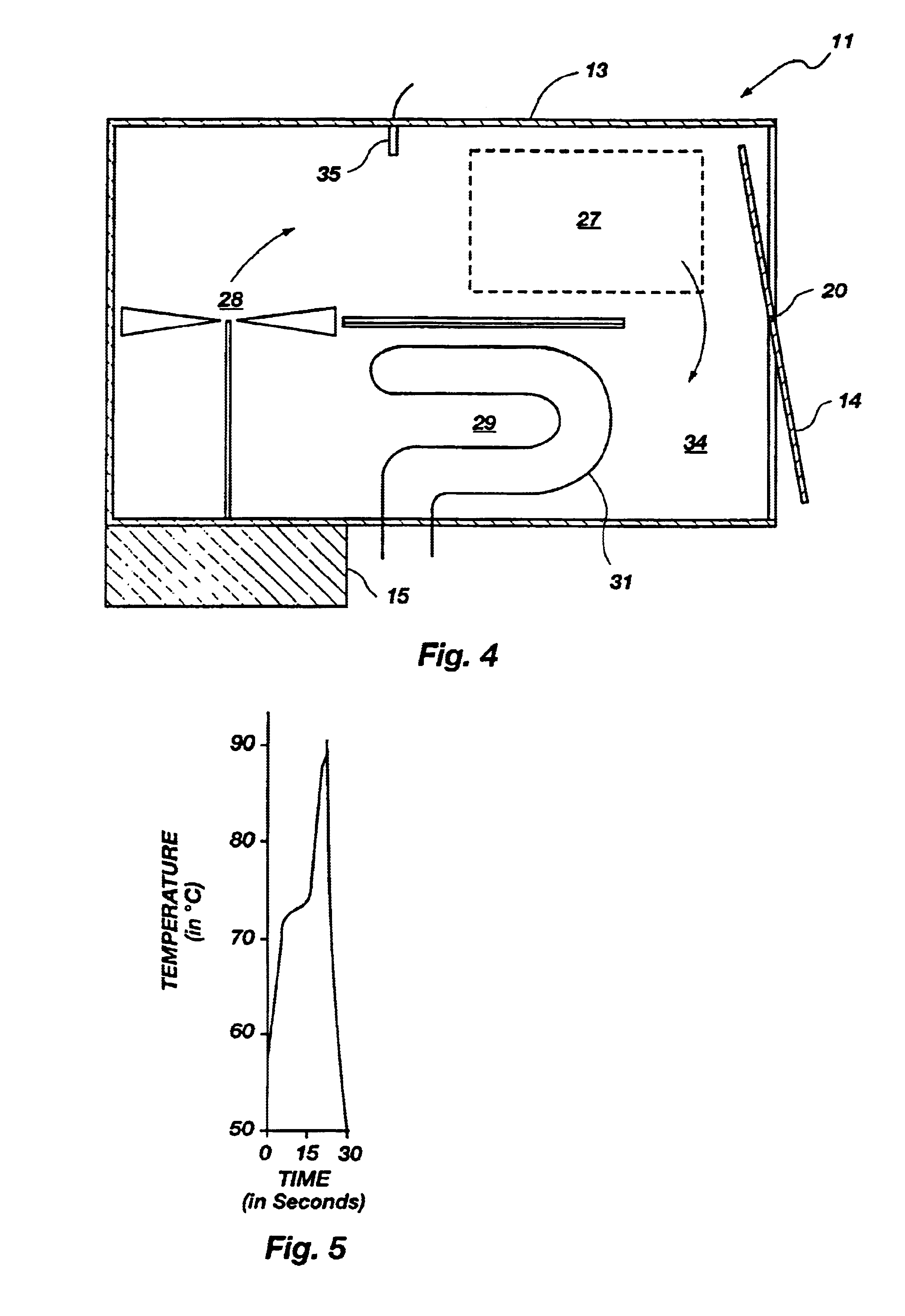

A thermal cycling method and device is disclosed. The device comprises a sample chamber whose temperature can be rapidly and accurately modulated over a range of temperatures needed to carry out a number of biological procedures, such as the DNA polymerase chain reaction. Biological samples are placed in glass micro capillary tubes and then located inside the sample chamber. A programmable controller regulates the temperature of the sample inside the sample chamber. Monitoring of the DNA amplification is monitored by fluorescence once per cycle or many times per cycle. The present invention provides that fluorescence monitoring of PCR is a powerful tool for DNA quantification.

Owner:UNIV OF UTAH RES FOUND

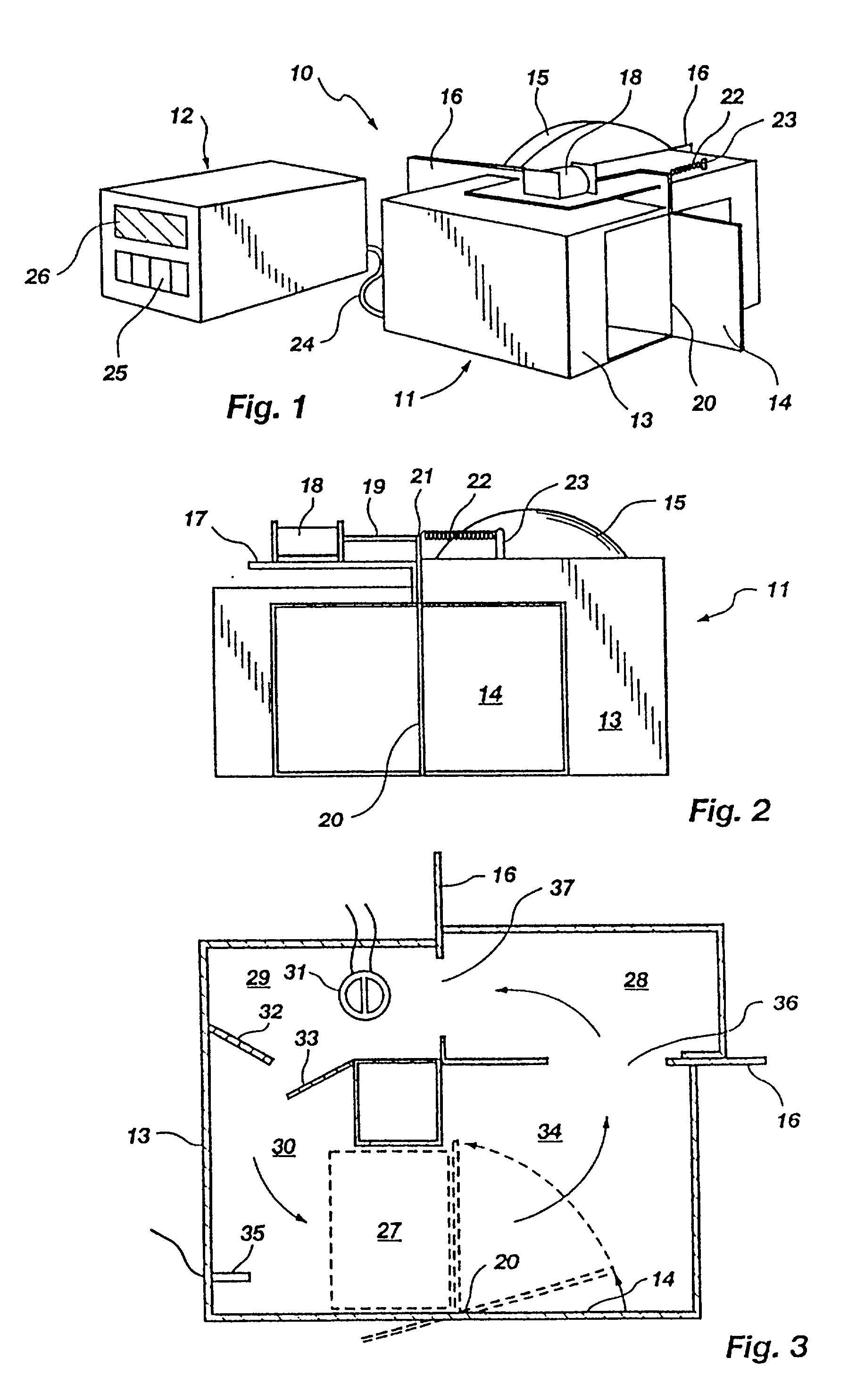

Method for rapid thermal cycling of biological samples

InactiveUS6787338B2Thermal massHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsTime profileAmplification dna

Owner:THE UNIV OF UTAH

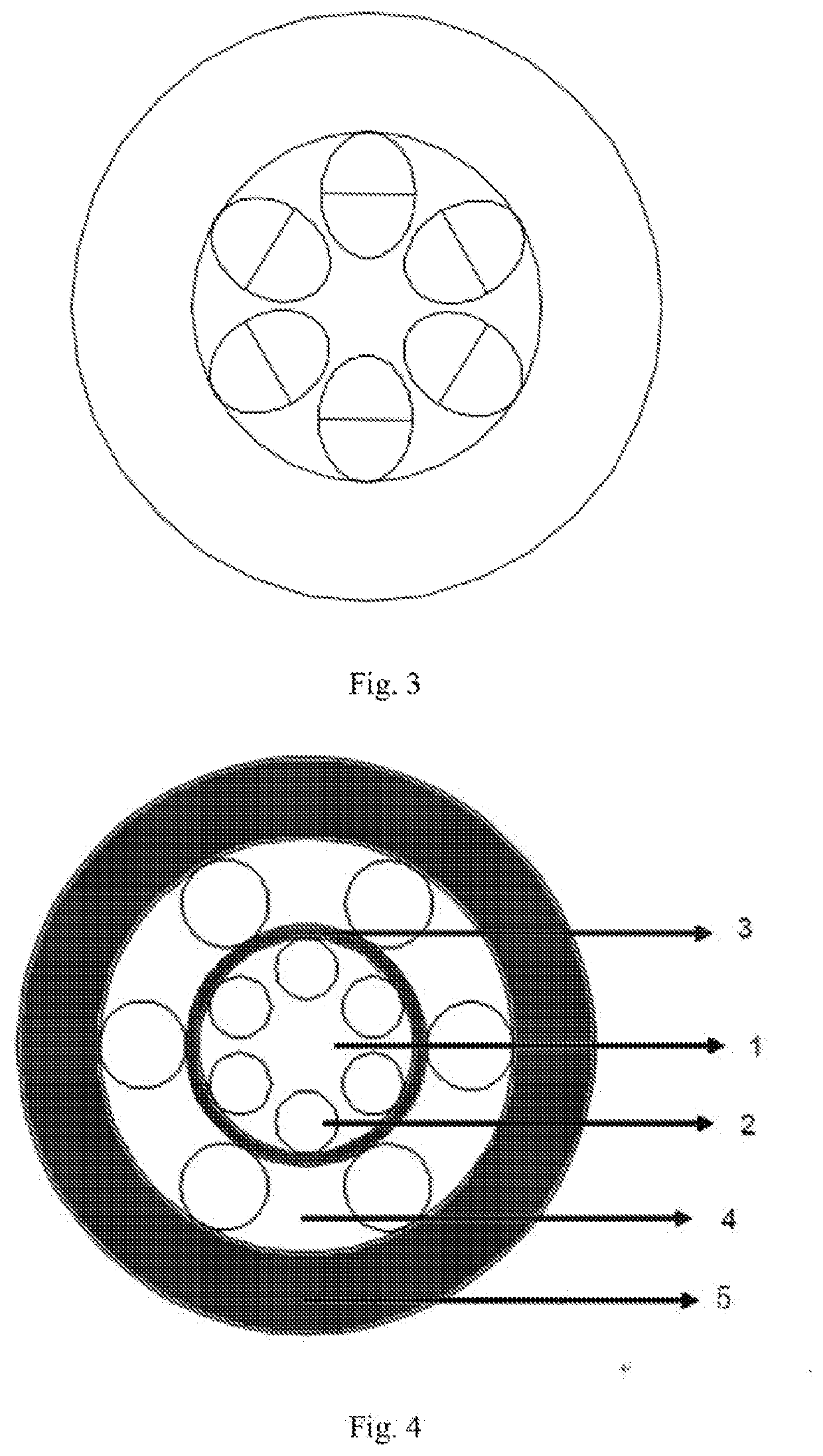

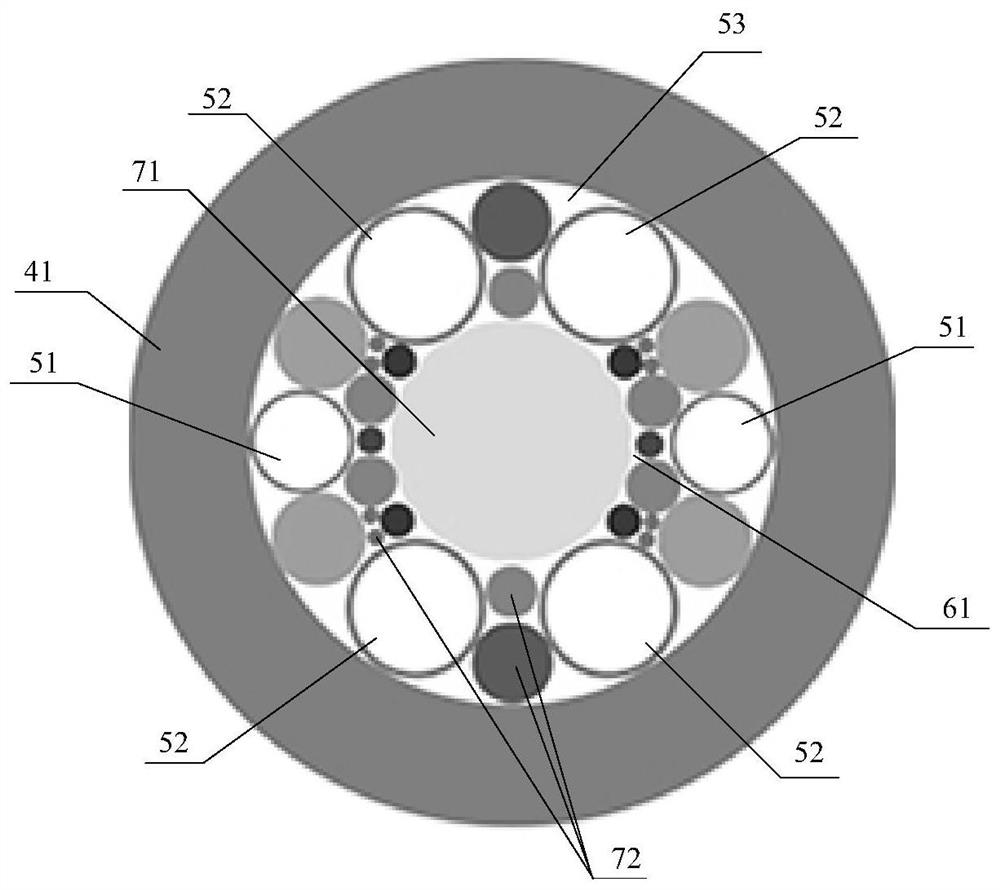

Hollow anti-resonance optical fiber

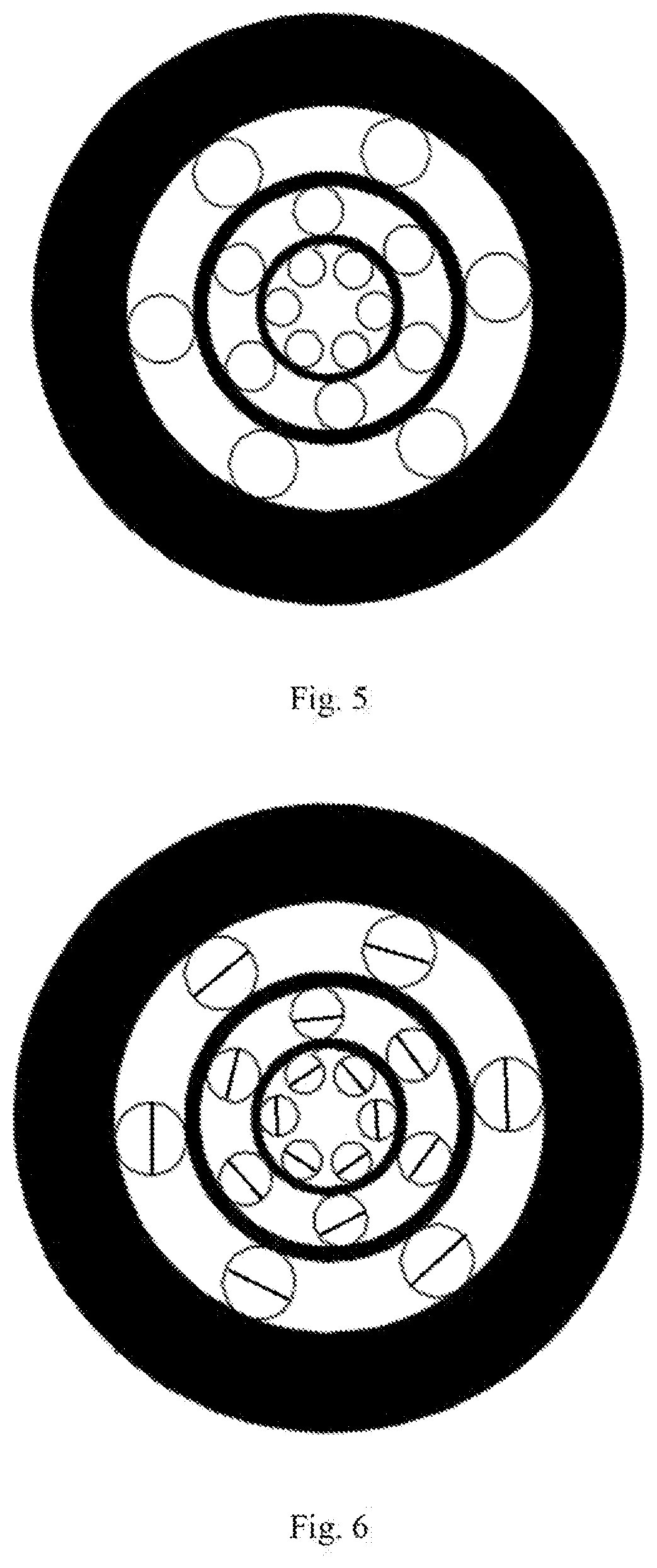

InactiveCN105807363AImprove efficiencyHigh sensitivityCladded optical fibreOptical waveguide light guideTransmission lossElectron

The invention discloses a hollow anti-resonance optical fiber, and belongs to the technical field of optics and laser photoelectrons.The basic structure of the hollow anti-resonance optical fiber comprises a fiber core area with low refraction rate and a wrapping layer area with high refraction rate.The wrapping layer area with high refraction rate is divided into an inner wrapping layer region and an outer wrapping layer region.The inner wrapping layer region is composed of one or two layers of micro capillary pipes.The fiber core area with low refraction rate is wrapped by the inner wrapping layer region.Compared with a traditional band gap type hollow-core photonic crystal fiber, the hollow anti-resonance optical fiber has the advantages of being large in spectral bandwidth, small in bending loss, low in transmission loss, high in damage threshold and capable of keeping single-modulus transmission.A high-efficiency and high-sensitivity ideal platform is created for nonlinear frequency conversion, trace gas / liquid detection, high-power pulse compression and other foremost application.

Owner:BEIJING UNIV OF TECH

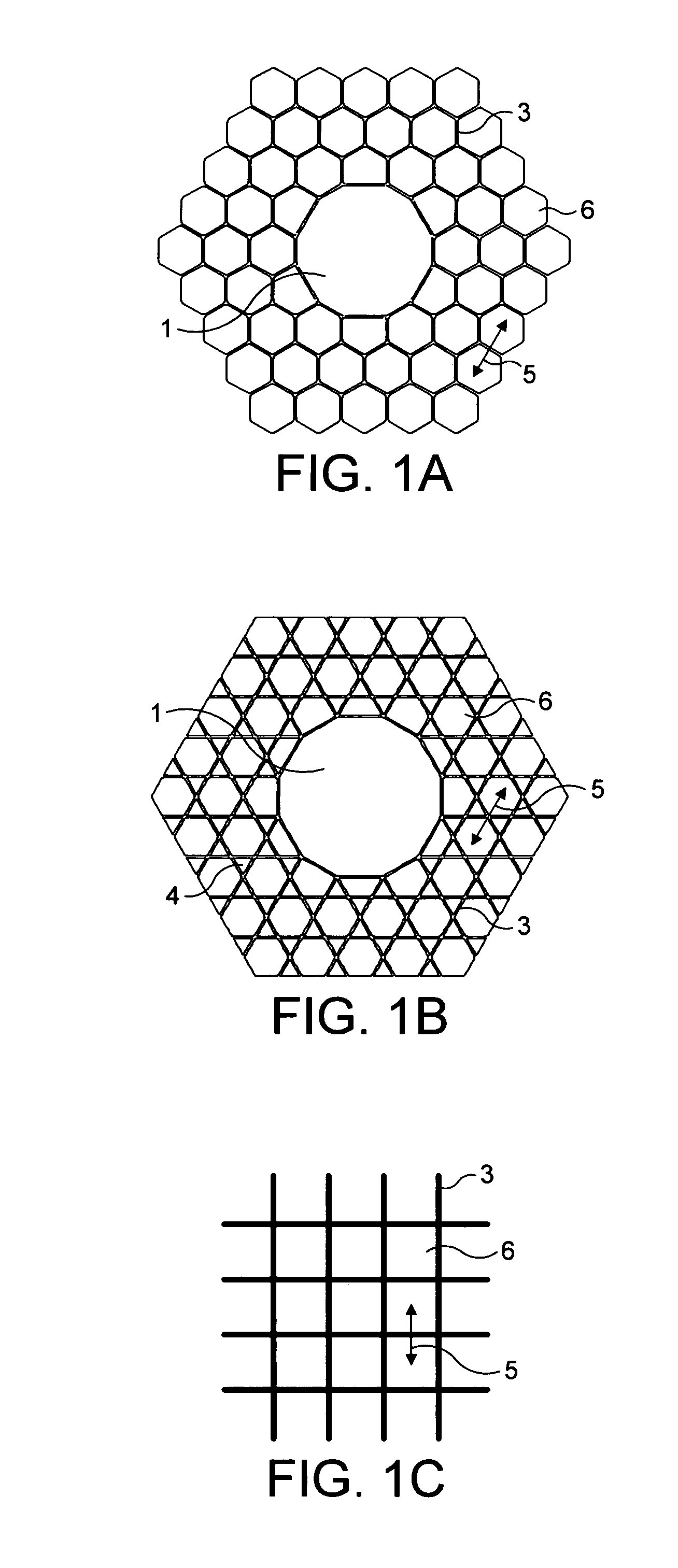

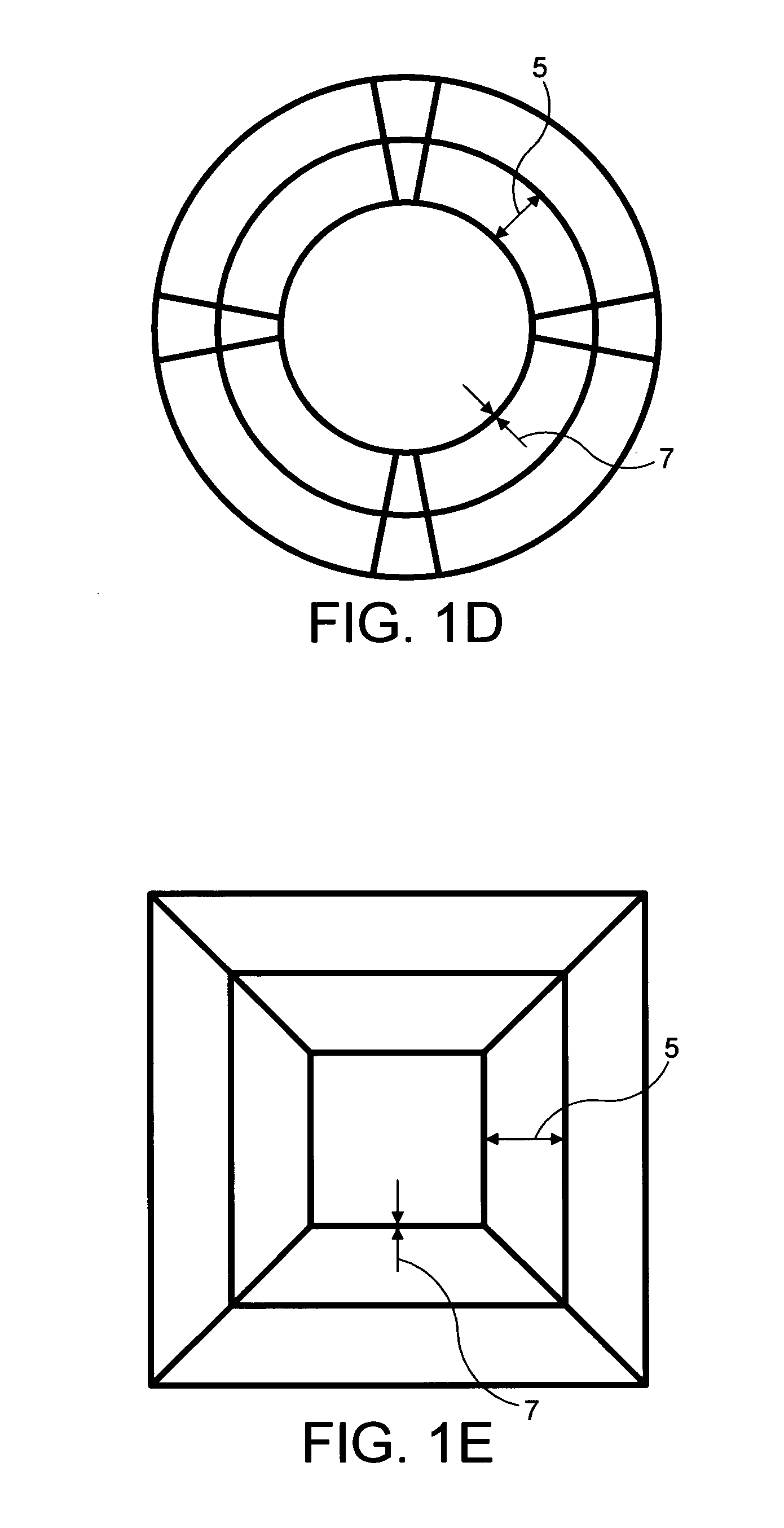

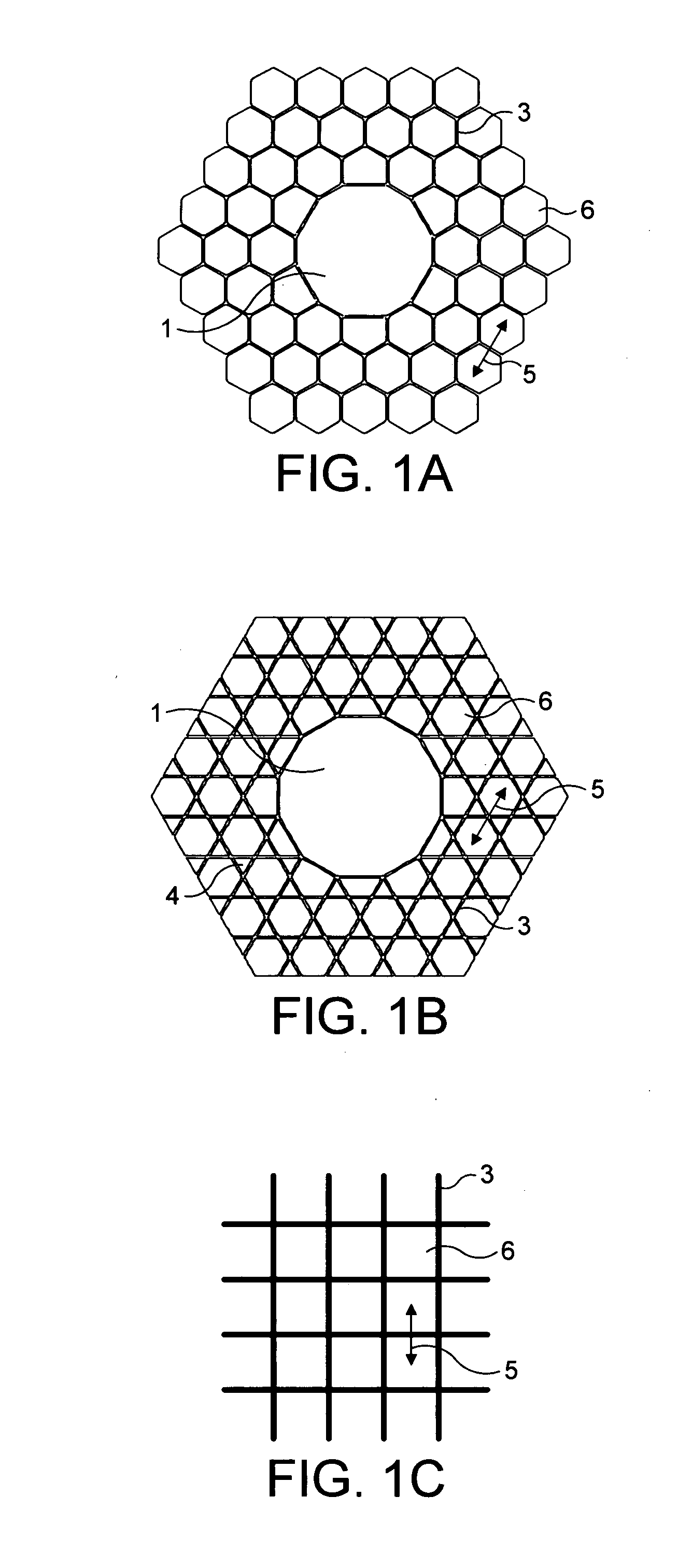

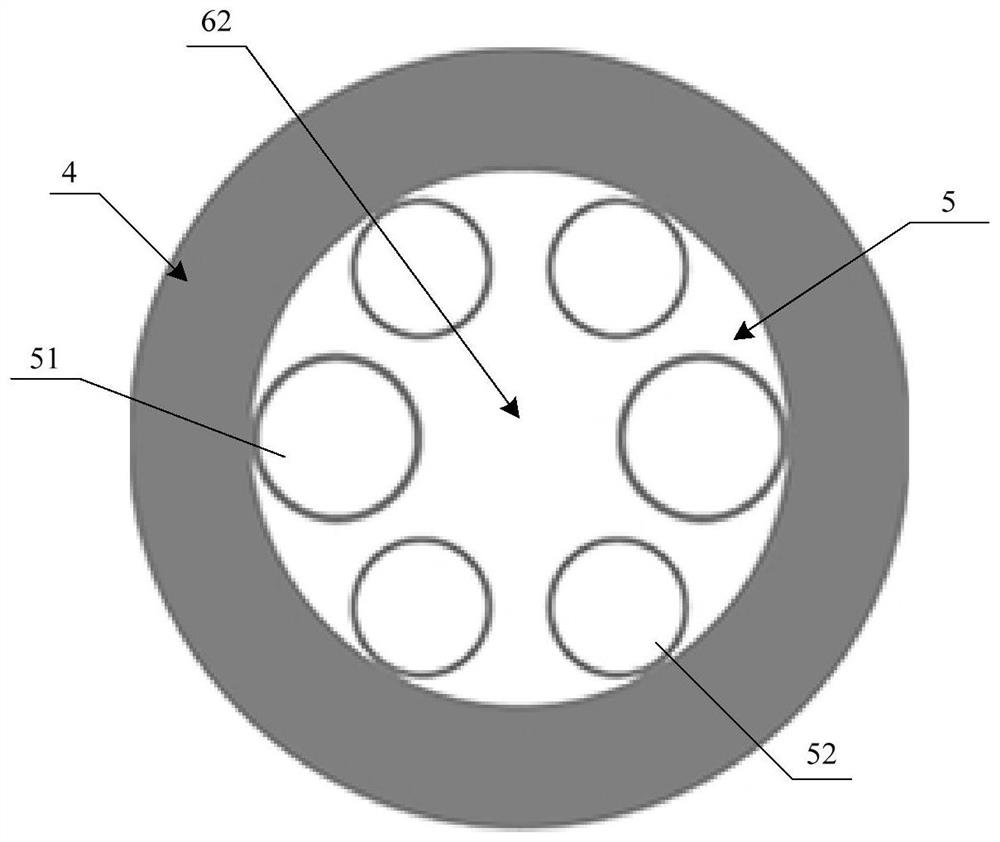

Hollow-core photonic crystal fibre

ActiveUS8306379B2Easy to makeWide transmission regionGlass making apparatusRadiation pyrometryRefractive indexLength wave

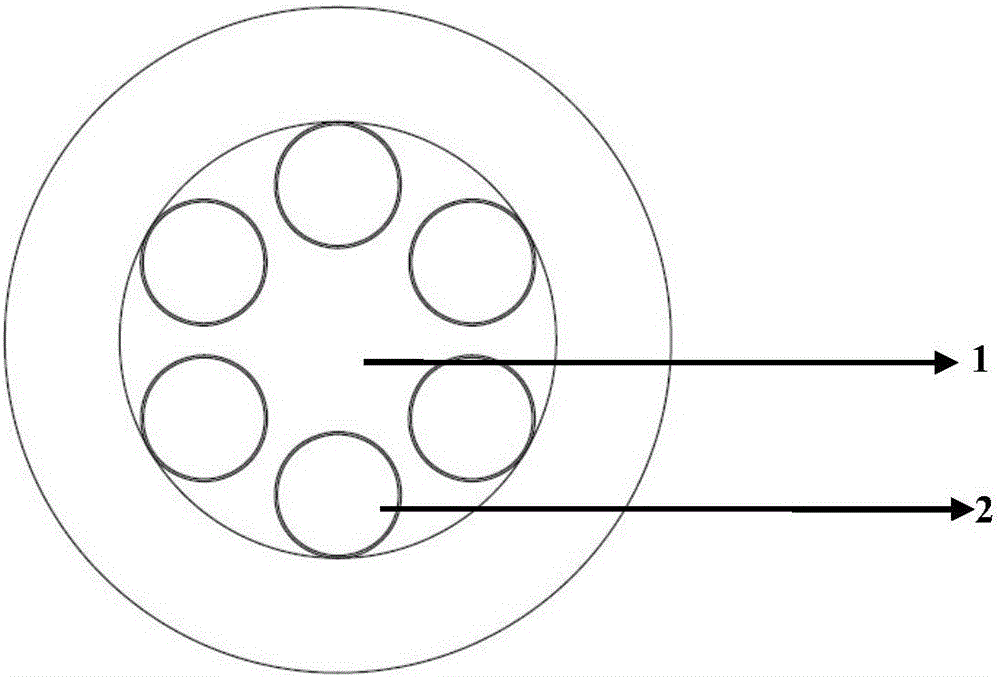

A hollow core photonic crystal fiber (HCPCF) having a wavelength of operation, the HCPCF comprising: a core region having a first refractive index; a cladding region surrounding the core region and comprising a plurality of microcapillaries arranged in a transverse structure having a pitch, the pitch of the structure being at least five times larger than the wavelength of operation, the cladding region having a second refractive index higher than the first refractive index.

Owner:GLOPHOTONICS

Cable jackets having designed microstructures and methods for making cable jackets having designed microstructures

Optical fiber cables (1001) comprising at least one optical fiber transmission medium (1006) and at least one elongated polymeric protective component (1002) surrounding at least a portion of the optical fiber transmission medium. The elongated polymeric protective component (1002) comprises a polymeric matrix material and a plurality of microcapillaries containing a polymeric microcapillary material, where the polymeric matrix material has a higher flexural modulus than the polymeric microcapillary material. Also disclosed are dies and methods for making such optical fiber cables and protective components.

Owner:DOW GLOBAL TECH LLC

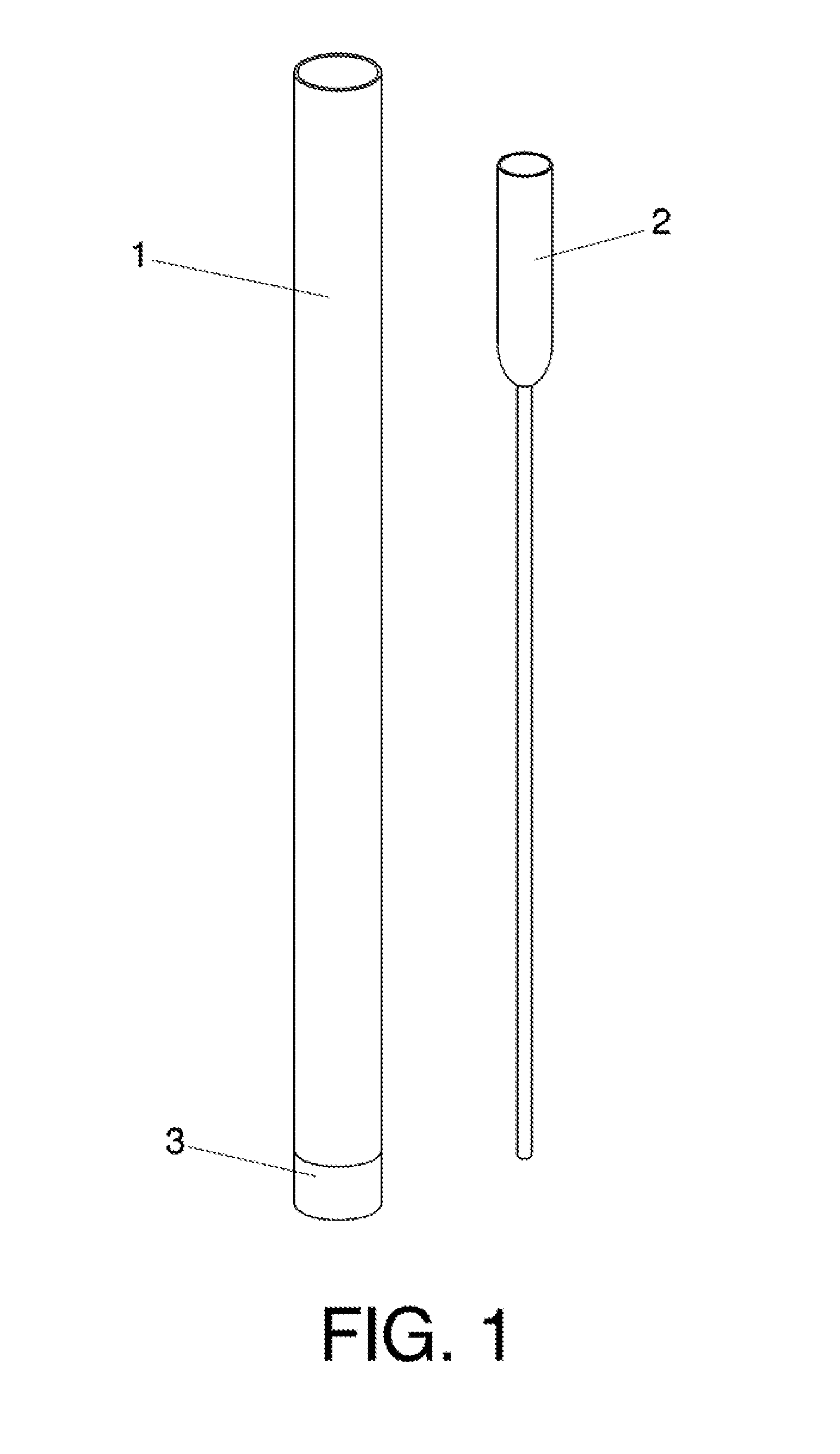

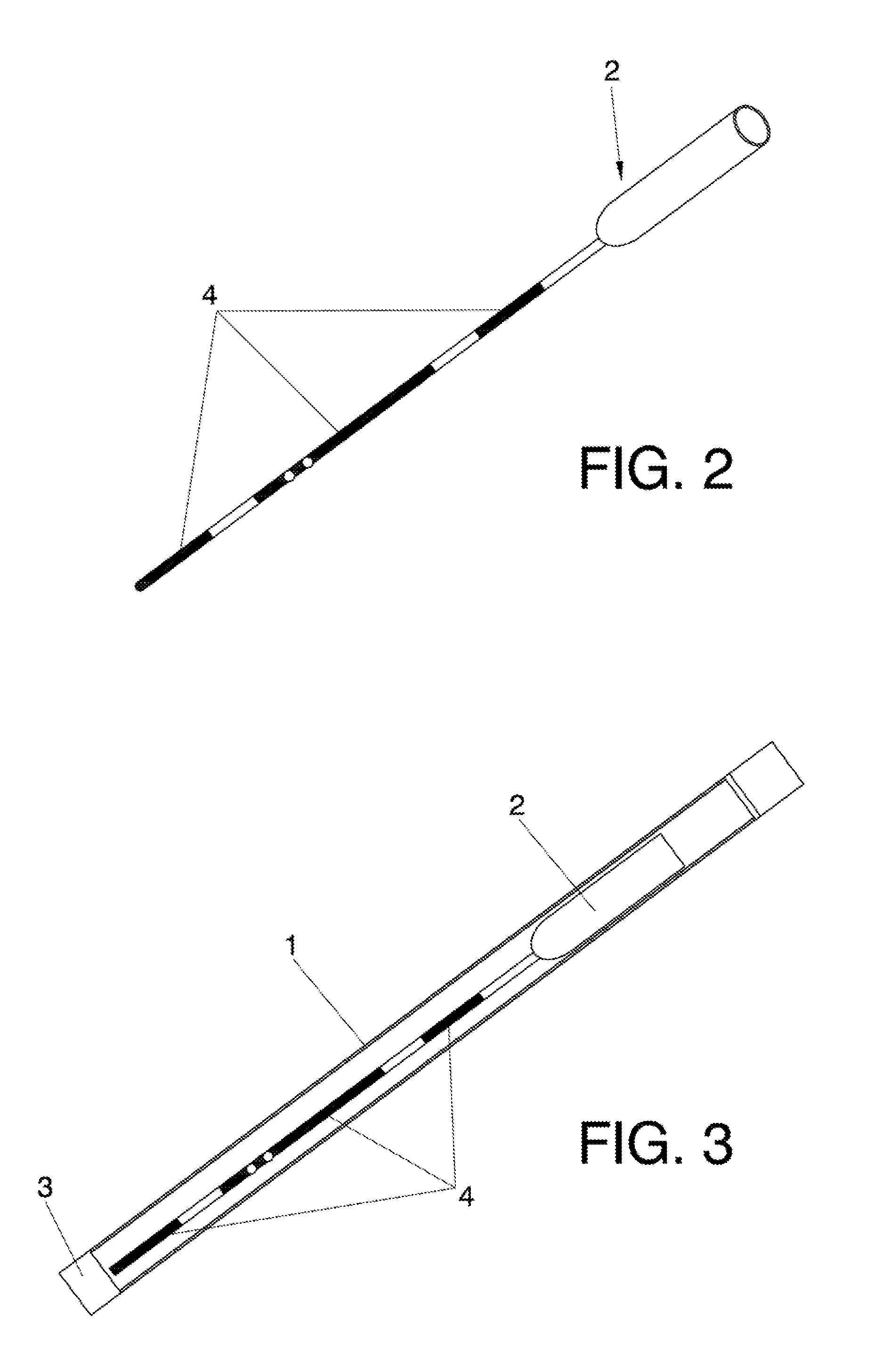

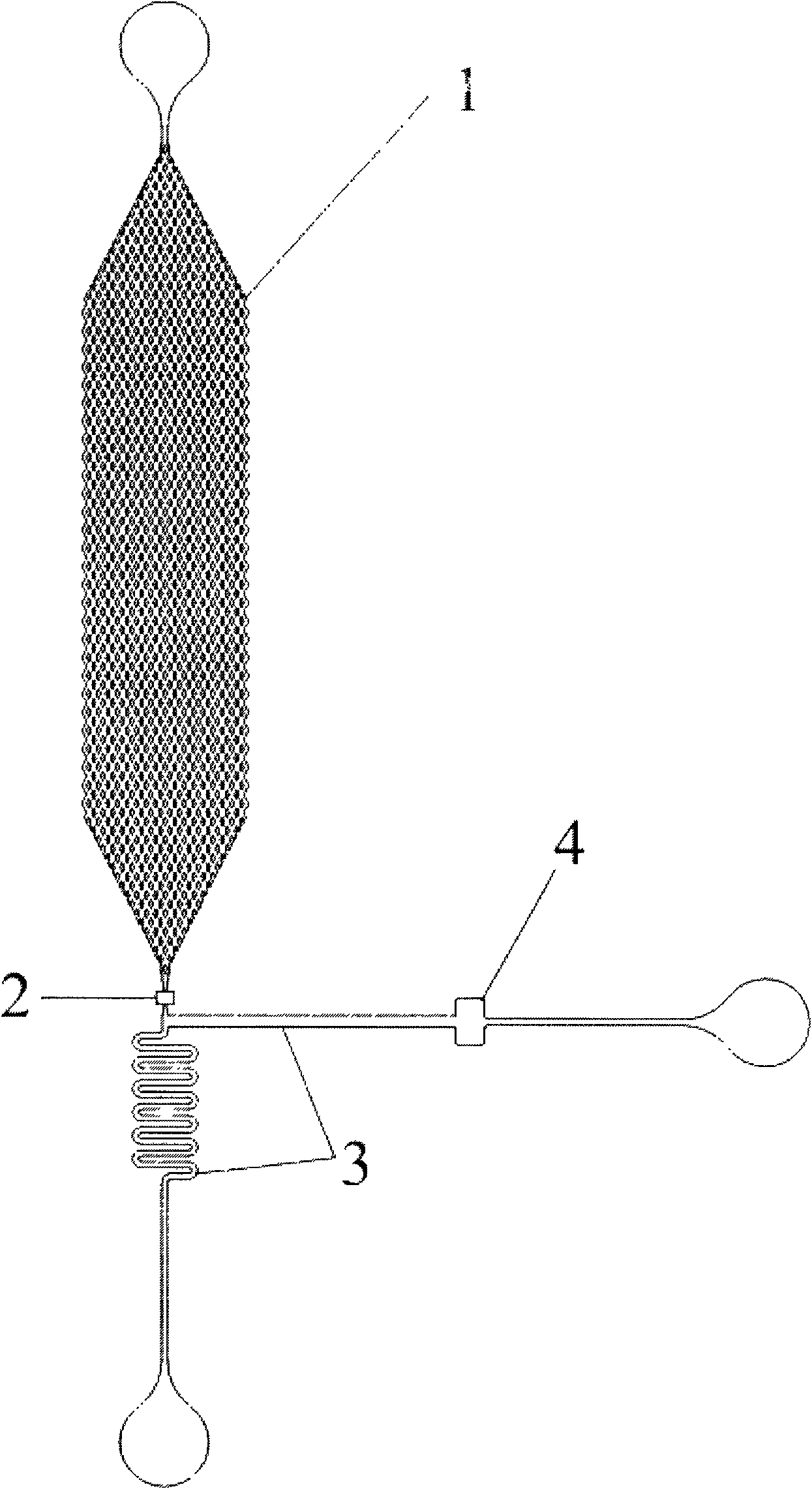

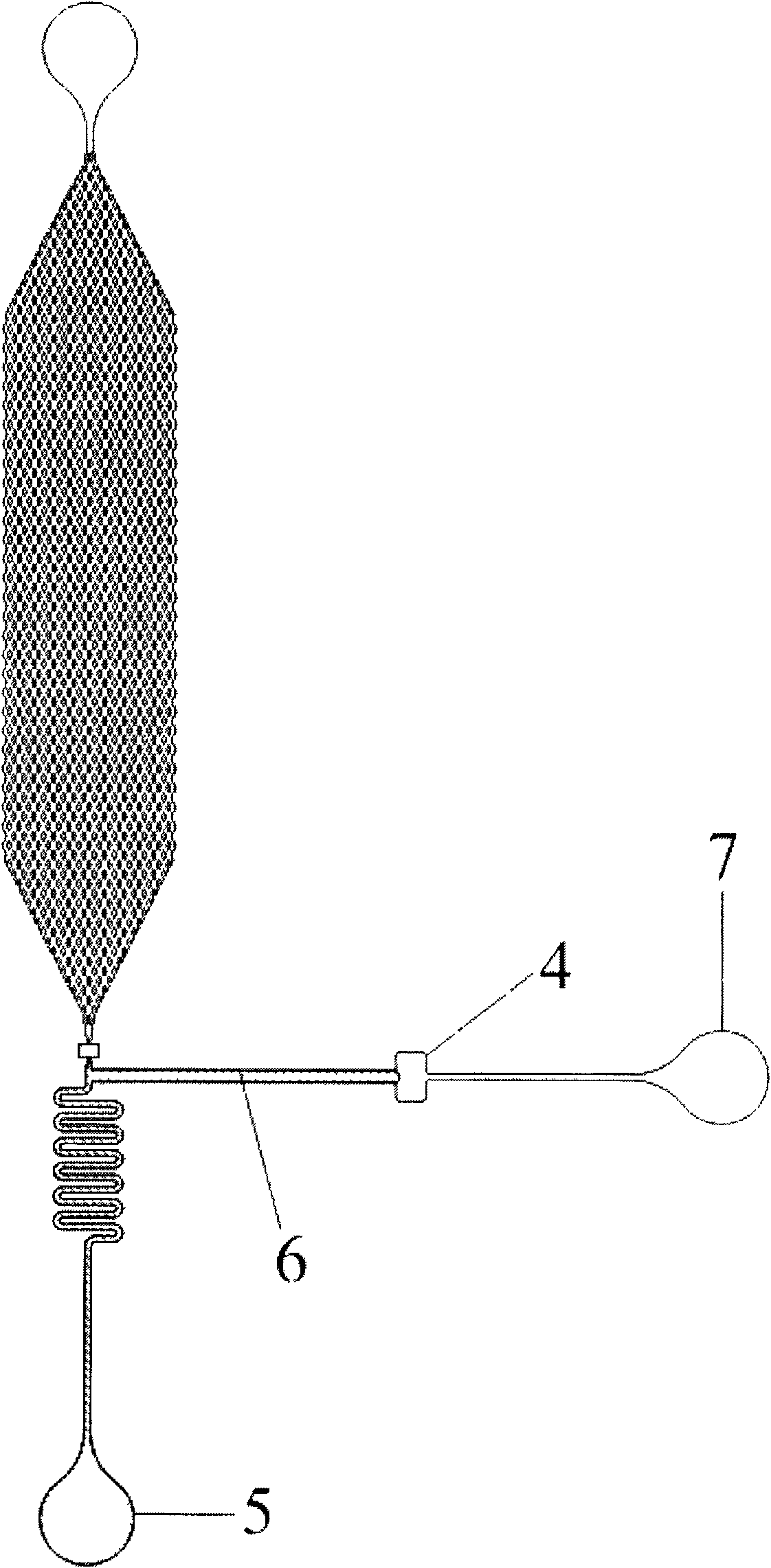

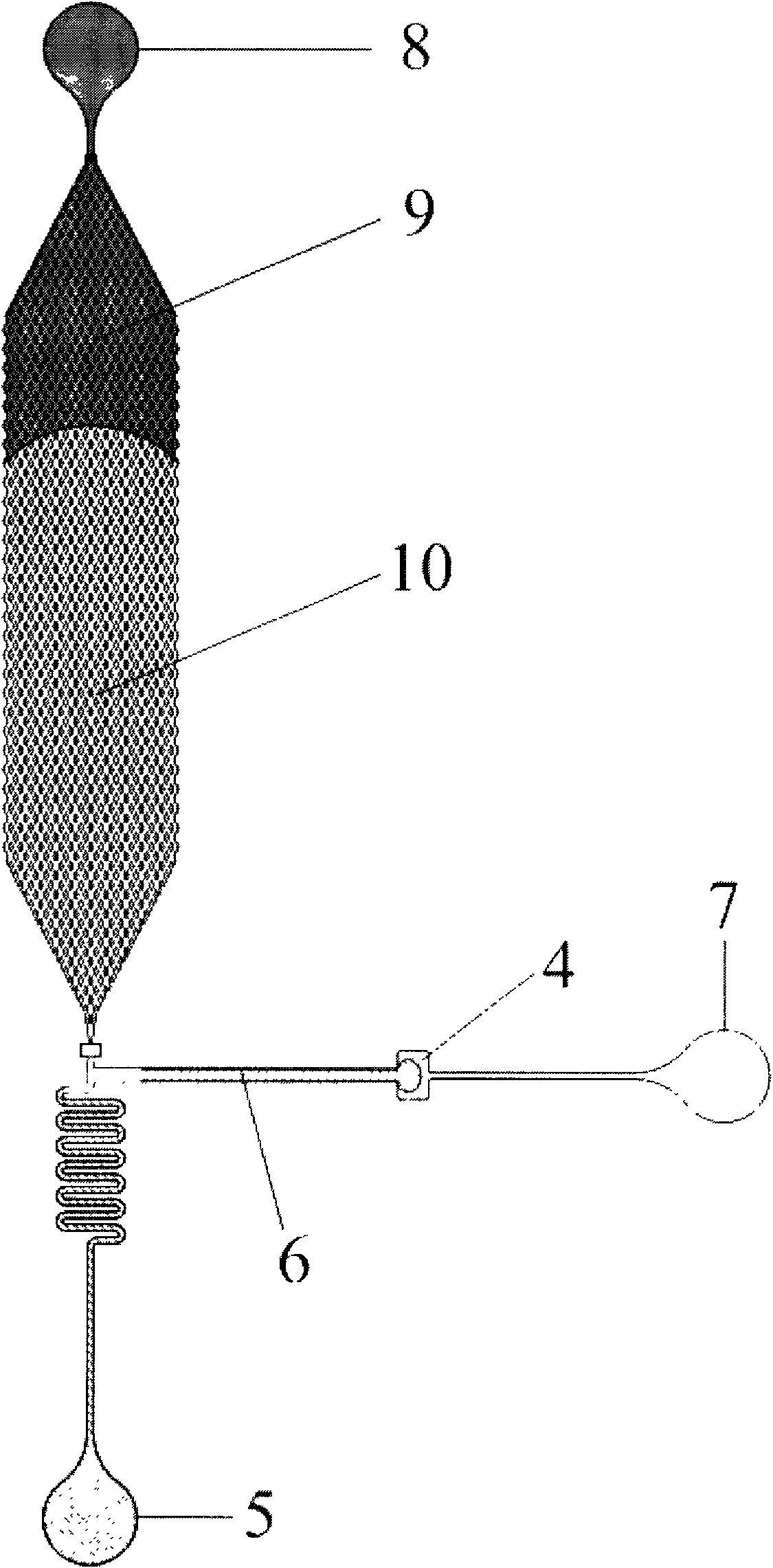

Closed ultra-rapid cell vitrification device and sealing procedure of the device

InactiveUS20110196358A1Reduce the risk of contaminationReduce concentrationDead animal preservationSurgical instruments for coolingEngineeringSlurry

The present invention provides a closed ultra-fast device for vitrification that reduces the risk of contamination; favors and increases the survival of human cells (e.g., oocytes, embryos, sperm, etc.) or non-human cells after thawing; and achieves ultra-fast cooling rates with a low concentration of cryo-protectors. The device of the present invention avoids risk of contamination, favors and increases the survival rate of human (oocytes, embryos or sperm, etc) or nonhuman cells after thawing, featuring ultra-rapid cooling rates and the use of low concentrations of cryo-protectors. The device comprises a protective sheath made of an inert, flexible and transparent material, inside of which a micro-capillary, preferably of quartz, is intended to house the cells that are to be vitrified. The protective sheath is adapted to be protectively sealed at its superior extremity, thereby creating a hermetic seal of the device and preventing the entry of coolant (liquid nitrogen, slush or slurry) into the protective sheath.

Owner:CRIADO SCHOLZ ENRIQUE +1

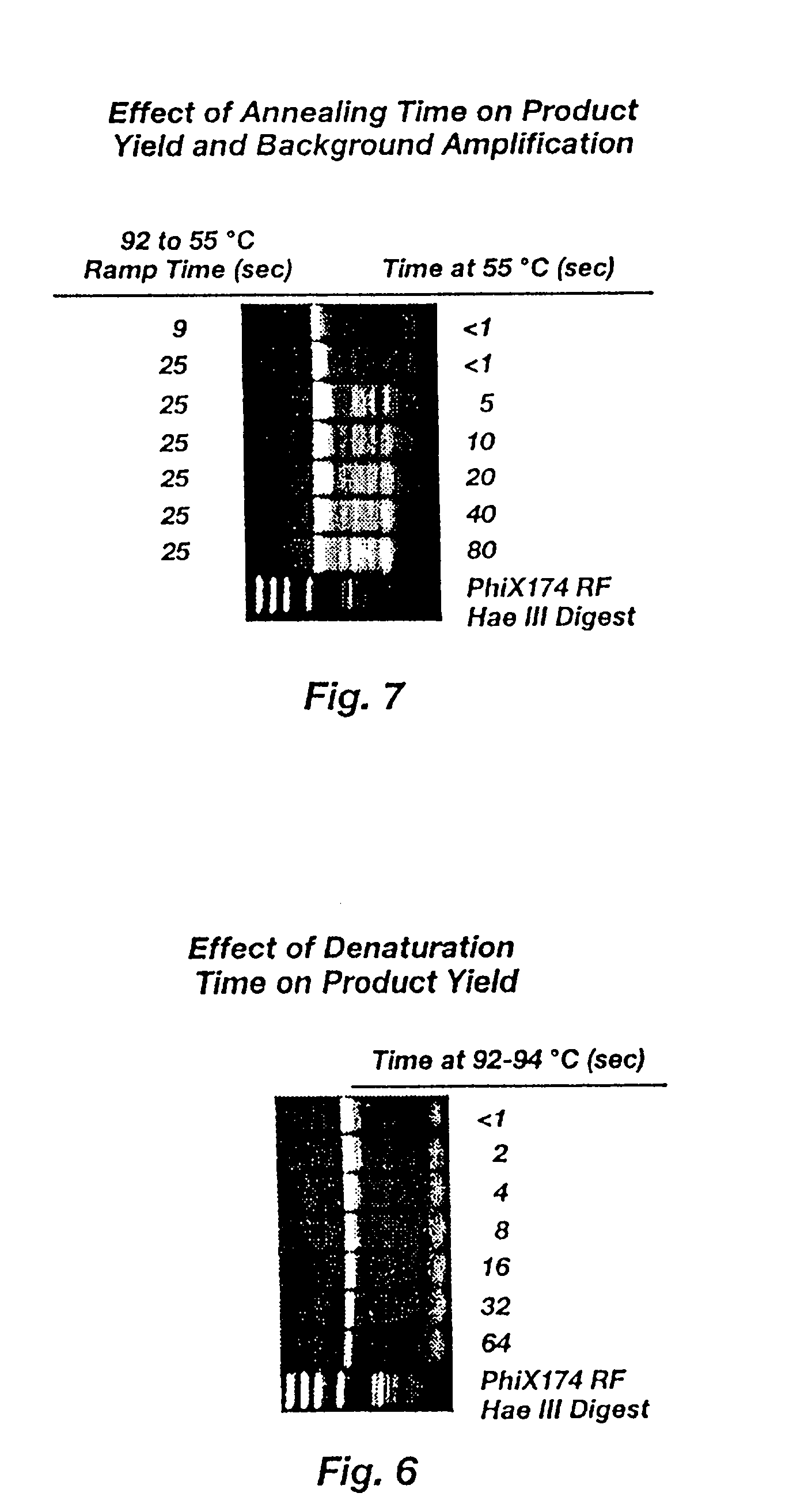

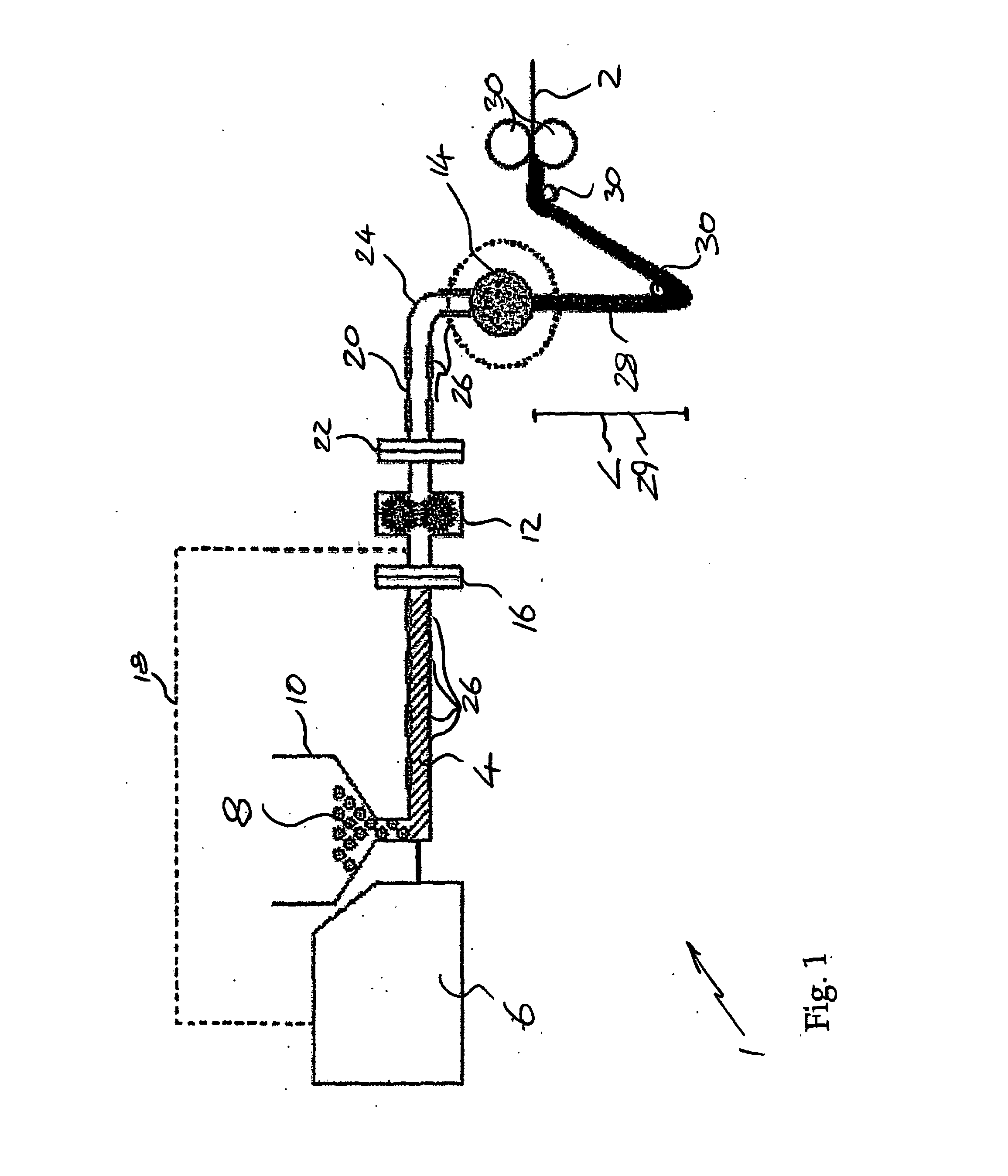

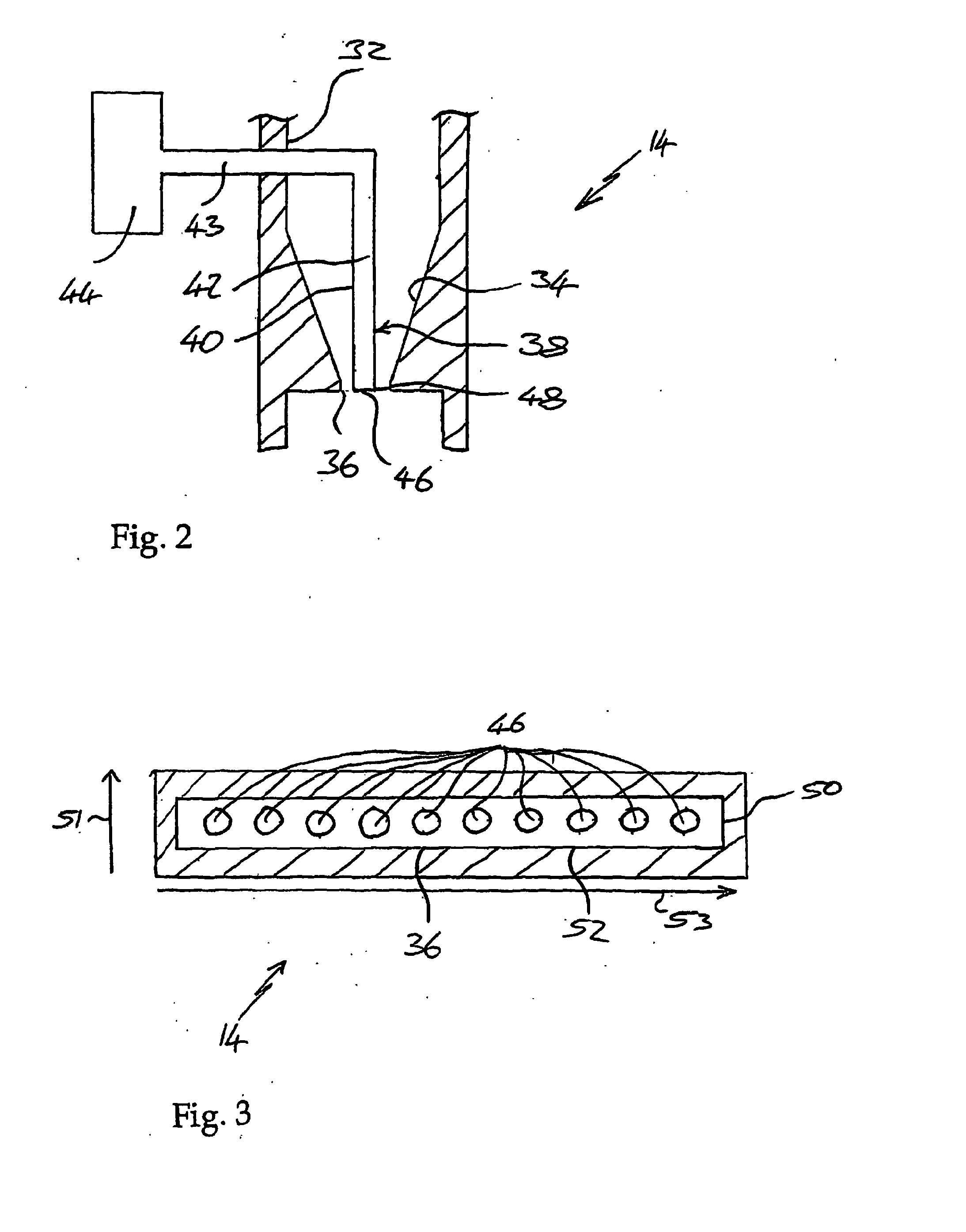

Method for rapid thermal cycling of biological samples

InactiveUS20010007759A1Thermal massHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsAmplification dnaTime profile

A thermal cycling method and device is disclosed. The device comprises a sample chamber whose temperature can be rapidly and accurately modulated over a range of temperatures needed to carry out a number of biological procedures, such a the DNA polymerase chain reaction. Biological samples are placed in glass micro capillary tubes and then located inside the sample chamber. A programmable controller regulates the temperature of the sample inside the sample chamber. Once a heating cycle is completed, the controller opens a door to the chamber for venting hot air out and cool ambient air is moved in. Temperature versus time profiles corresponding to optimum denaturation, annealing and elongation temperatures for amplification of DNA are achieved by the present invention.

Owner:THE UNIV OF UTAH

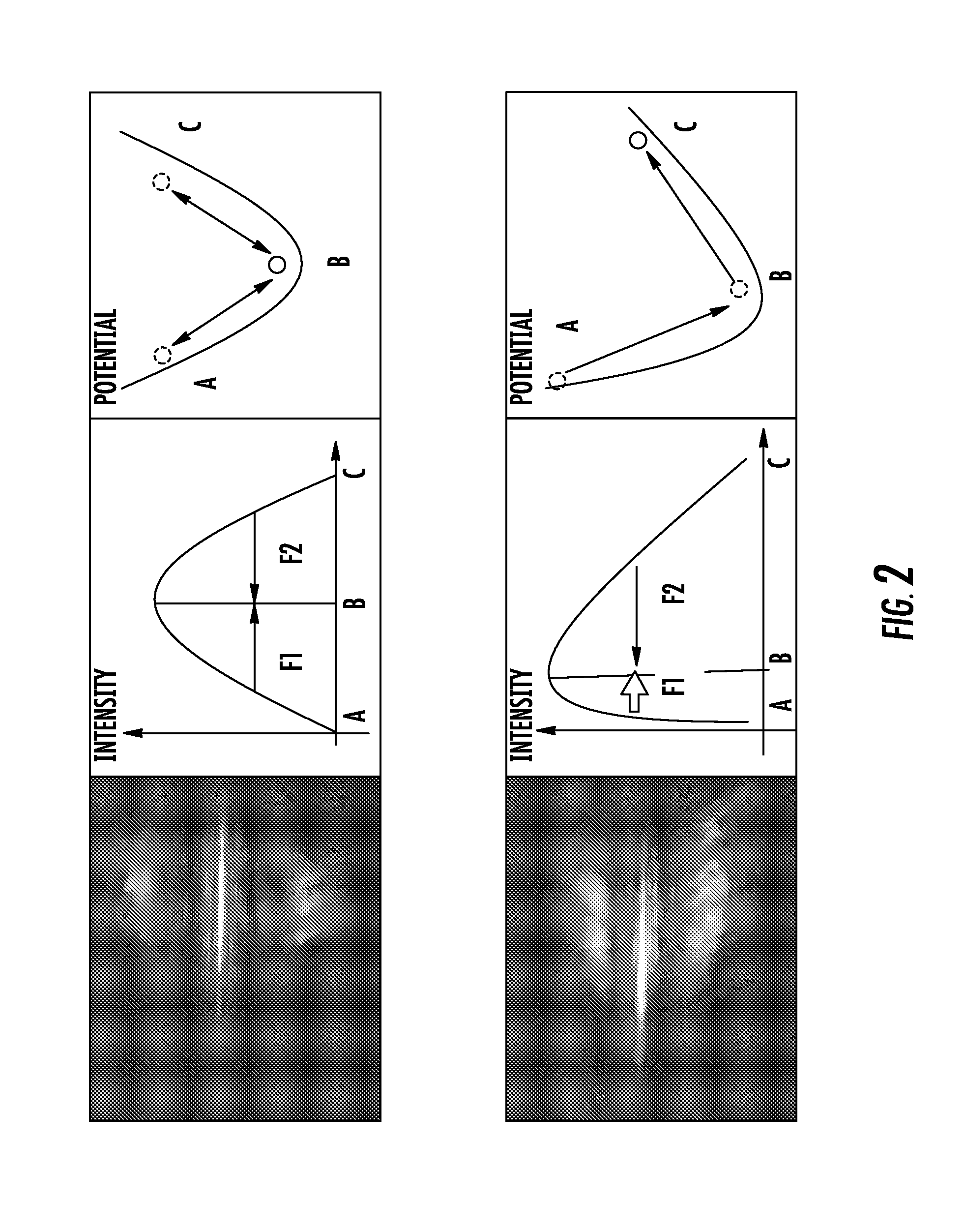

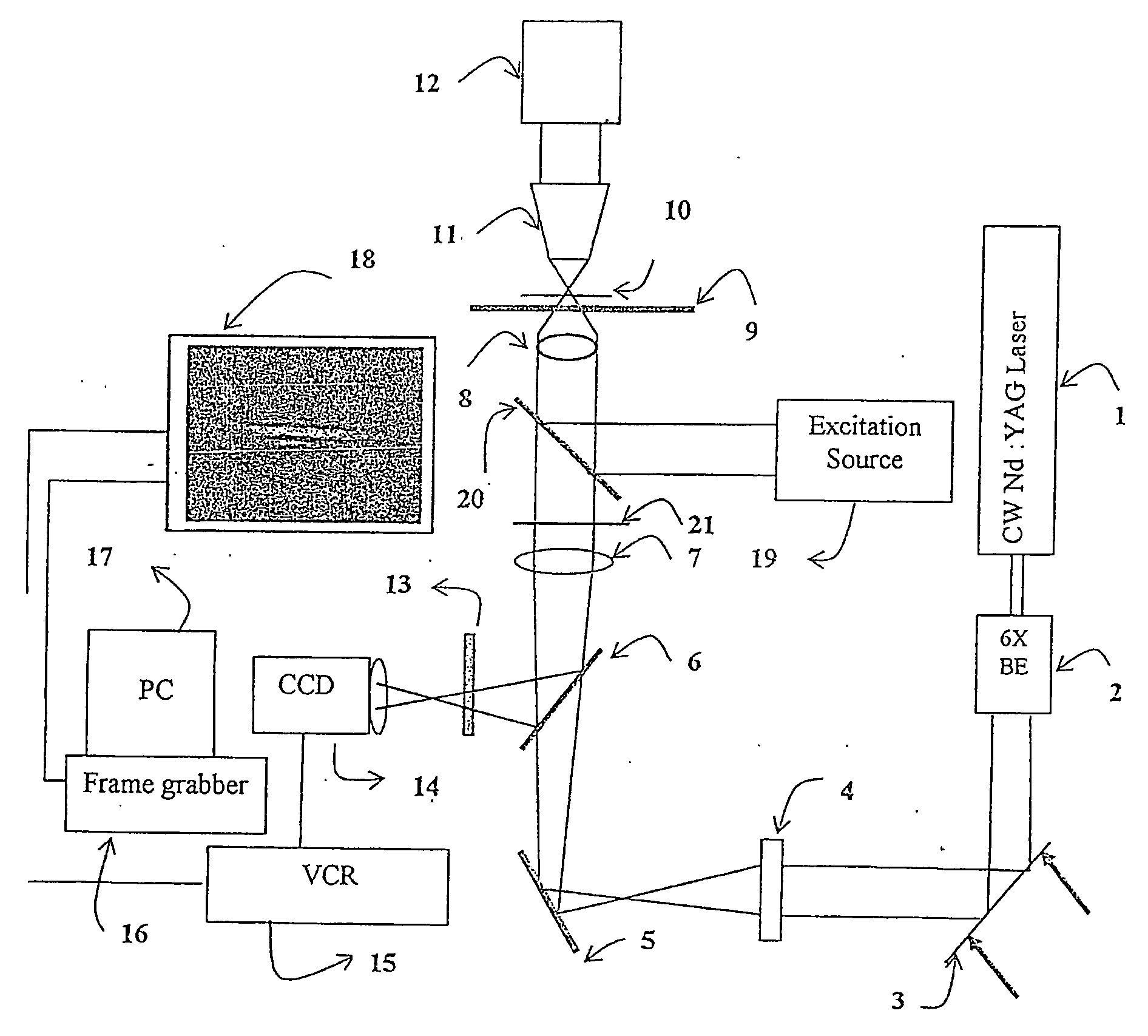

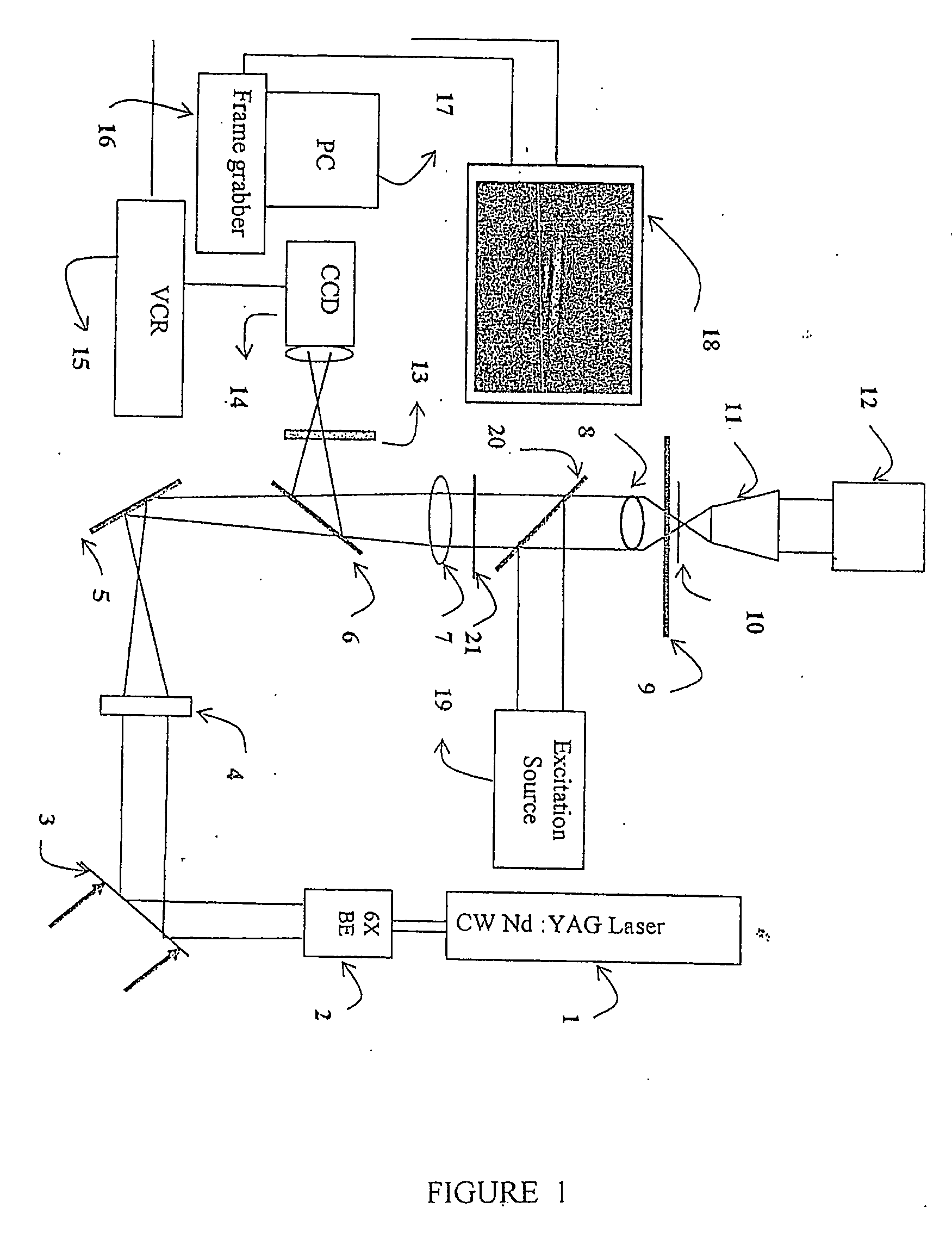

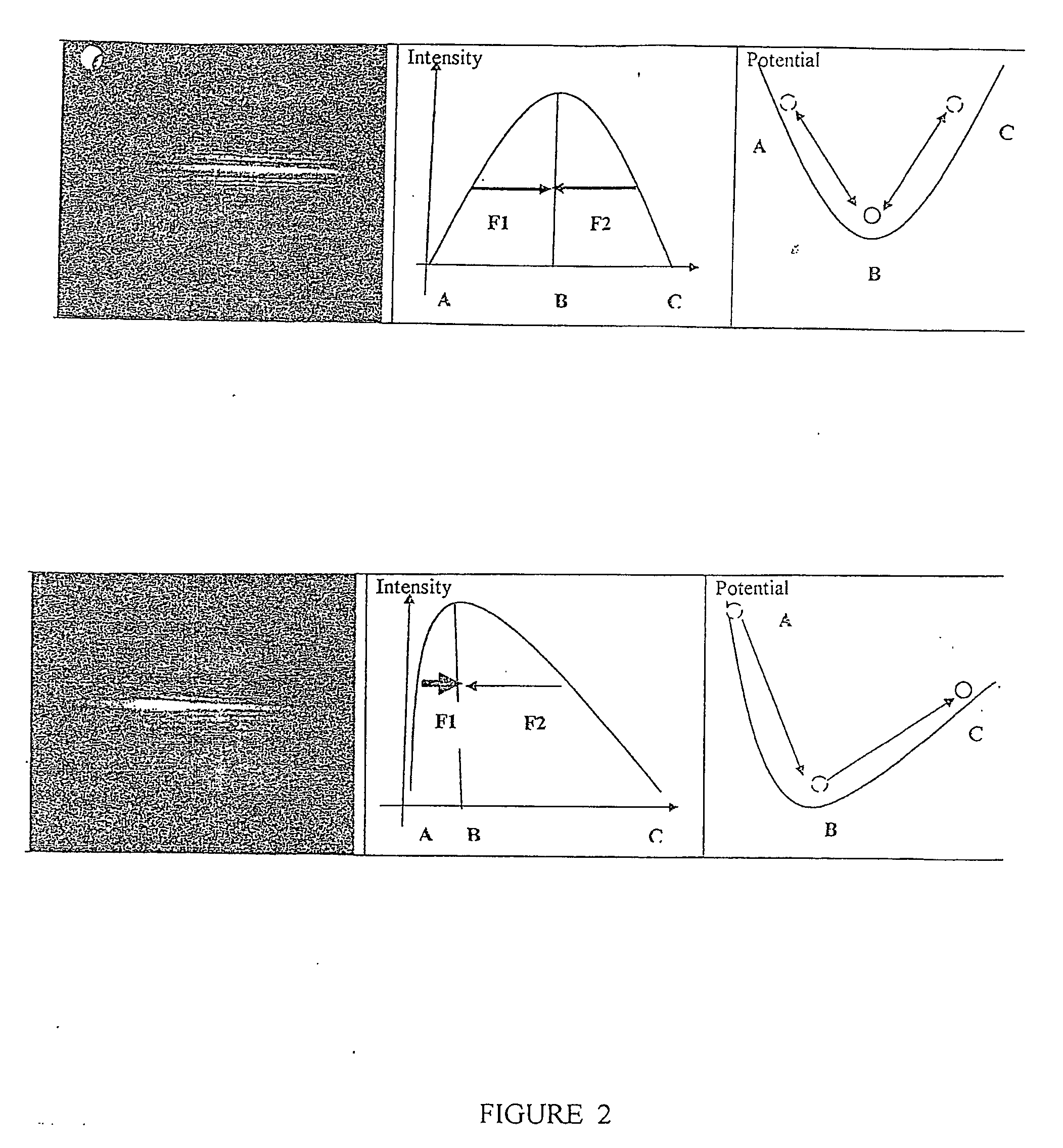

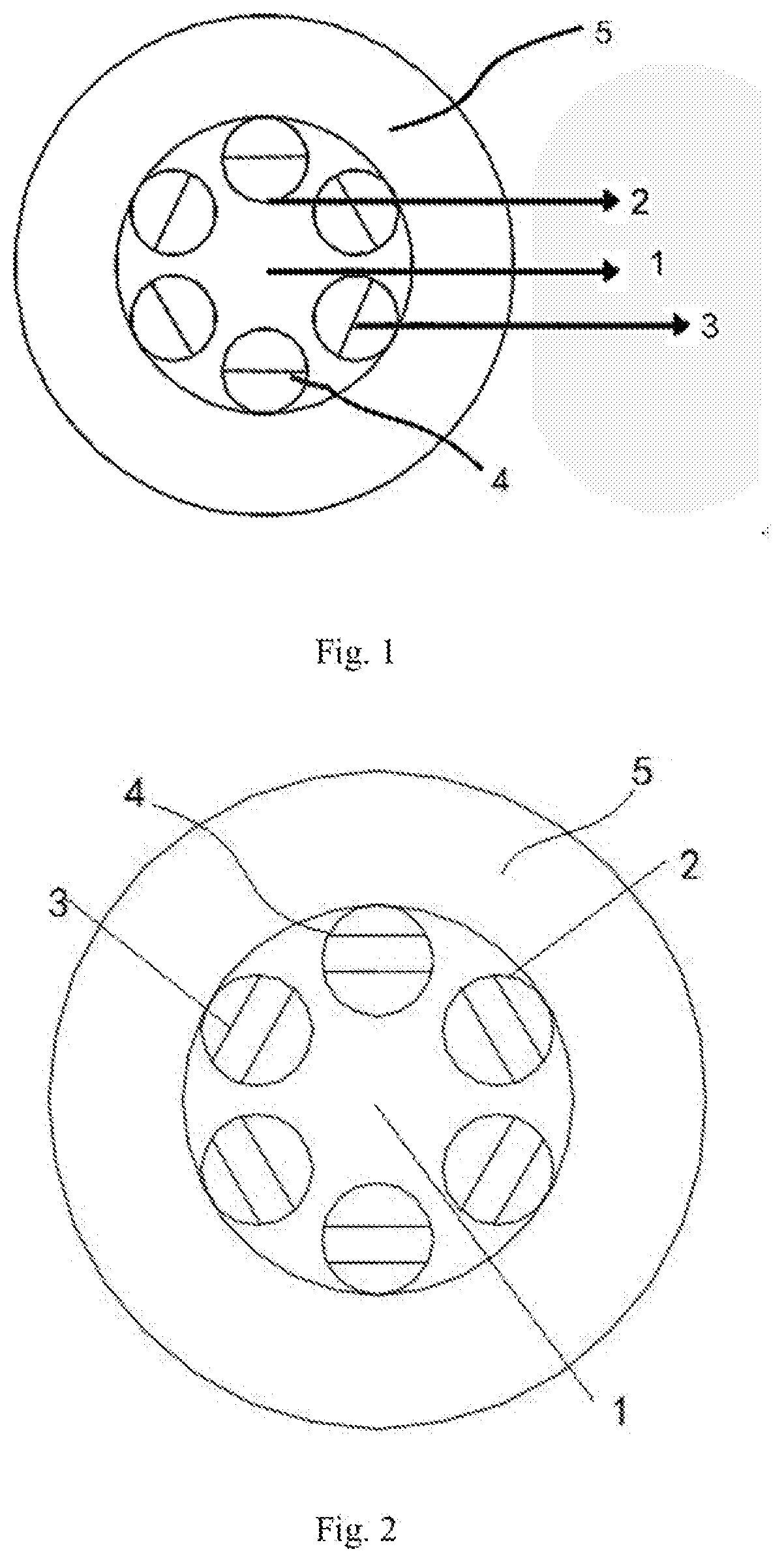

Apparatus and method for transport of microscopic object(s)

A system and the method for transport of microscopic objects / particles involving the use of laser source operatively connected to a microscope objective which is adapted to generate optical focal spots on said particle(s) with asymmetric intensity profile in transverse plane followed by varying the said asymmetry of the gradient optical forces on the micron sized object / particles to thereby transport the microscopic object(s). The system and the method can be used to transport microscopic objects including i) transportation of cells and intra-cellular organelles, ii) acceleration of microscopic objects along any direction in a plane transverse to the direction of propagation of laser beam, iii) optical channeling of objects through a micro-capillary from one micro-well to another and transfer to another channel after desired processing, iv) sorting of microscopic objects, v) optical control of micro-machines, micro-fluidic devices etc.

Owner:SEC

Preparation method of sapphire micro-capillary and die used in preparation method

InactiveCN104088011AImprove performanceHigh hardnessPolycrystalline material growthBy pulling from meltHigh rateCrucible

The invention provides a preparation method of a sapphire micro-capillary. An edge-defined film fed lifting growth technology is utilized. The preparation method comprises the following steps of (1) selecting a raw material, i.e., selecting high-purity aluminum oxide as the raw material; (2) machining a die; (3) placing the raw material in a crack between an outer die and an inner die, then, placing the die into a crucible, and next, placing the crucible in a crystal growing furnace; and (4) vacuumizing the crystal growing furnace, heating to melt aluminum oxide to form a melt, then, lifting the melt to the top of the inner die, starting to drop seed crystals, seeding and lifting. By using the method provided by the invention, defects that bubbles are generated on inner and outer walls of a machined sapphire pipe, and the parts containing the bubbles on the inner and outer walls need to be polished are avoided, and the one-step formation of the sapphire micro-capillary with a small internal diameter is realized; and in addition, the preparation method has the advantages of simple process, convenience in machining, high rate of finished products and the like.

Owner:牛玥

Apparatus and method for transport of microscopic object(s)

InactiveUS20070146714A1High gradientLow stiffnessRadiation pyrometrySpectrum investigationTransverse planeLaser source

A system and the method for transport of microscopic objects / particles involving the use of laser source operatively connected to a microscope objective which is adapted to generate optical focal spots on said particle(s) with asymmetric intensity profile in transverse plane followed by varying the said asymmetry of the gradient optical forces on the micron sized object / particles to thereby transport the microscopic object(s). The system and the method can be used to transport microscopic objects including i) transportation of cells and intra-cellular organelles, ii) acceleration of microscopic objects along any direction in a plane transverse to the direction of propagation of laser beam, iii) optical channeling of objects through a micro-capillary from one micro-well to another and transfer to another channel after desired processing, iv) sorting of microscopic objects, v) optical control of micro-machines, micro-fluidic devices etc. Importantly the apparatus and the method of the invention would have use in various biotechnological and micro electromechanical systems. Also the system and method for optical transportation of microscopic objects, would be capable of transporting objects of varying dimensions ranging from sub-micron to few tens of microns.

Owner:SEC

Hollow-Core Photonic Crystal Fibre

ActiveUS20100328658A1Control thicknessEasy to makeOptical articlesAdhesivesRefractive indexLength wave

A hollow core photonic crystal fibre (HCPCF) having a wavelength of operation, the HCPCF comprising: a core region having a first refractive index; a cladding region surrounding the core region and comprising a plurality of microcapillaries arranged in a transverse structure having a pitch, the pitch of the structure being at least five times larger than the wavelength of operation, the cladding region having a second refractive index higher than the first refractive index.

Owner:GLOPHOTONICS

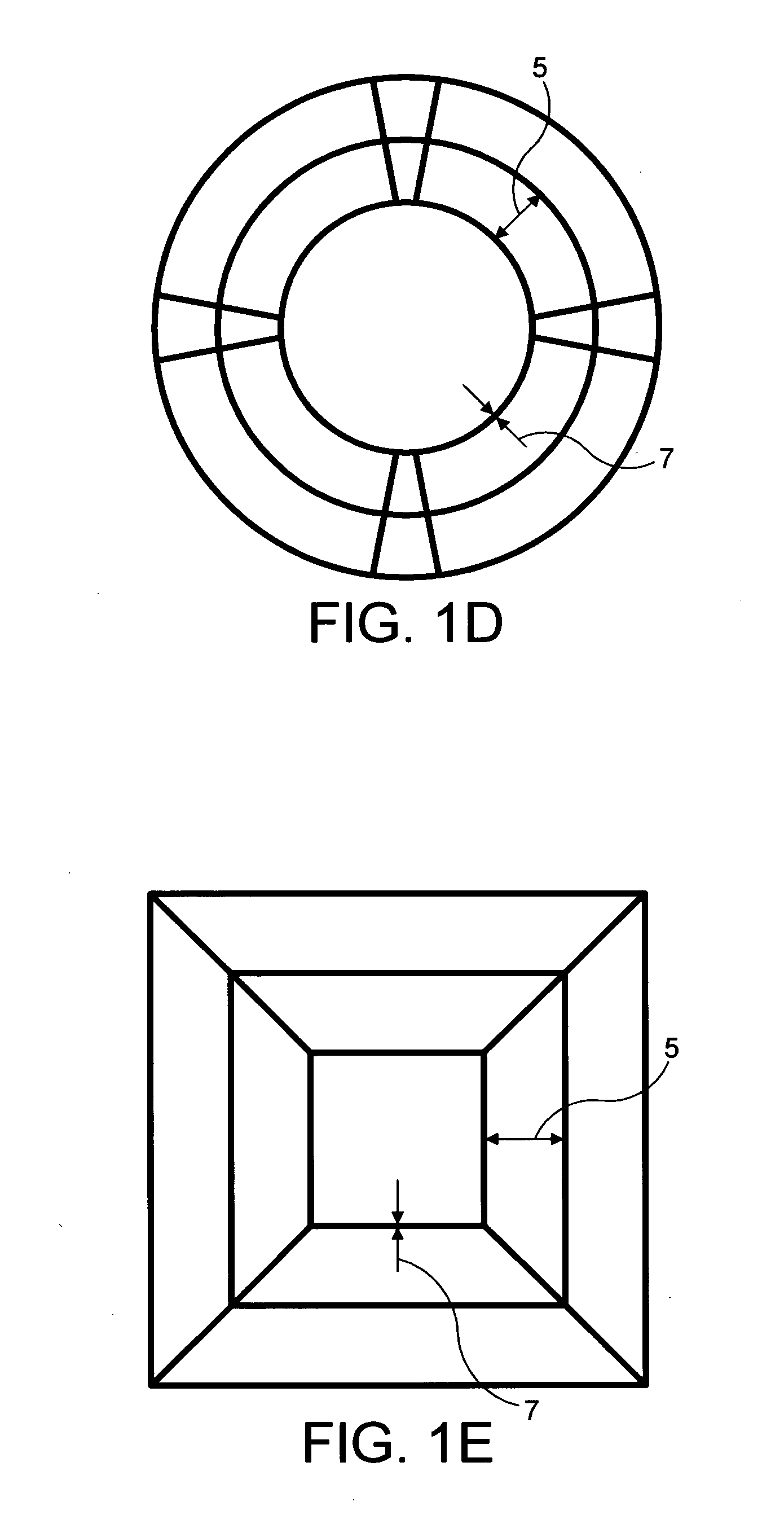

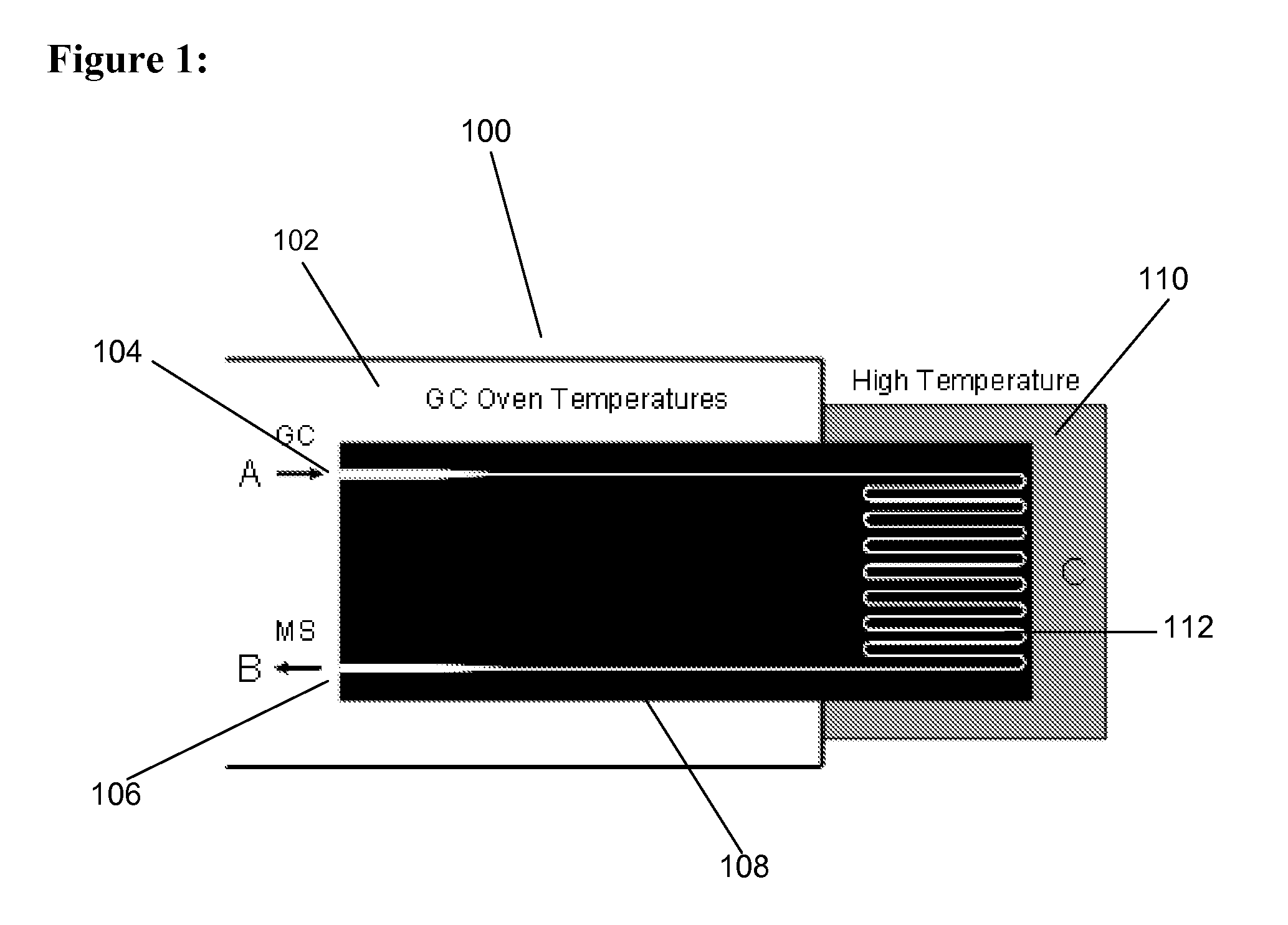

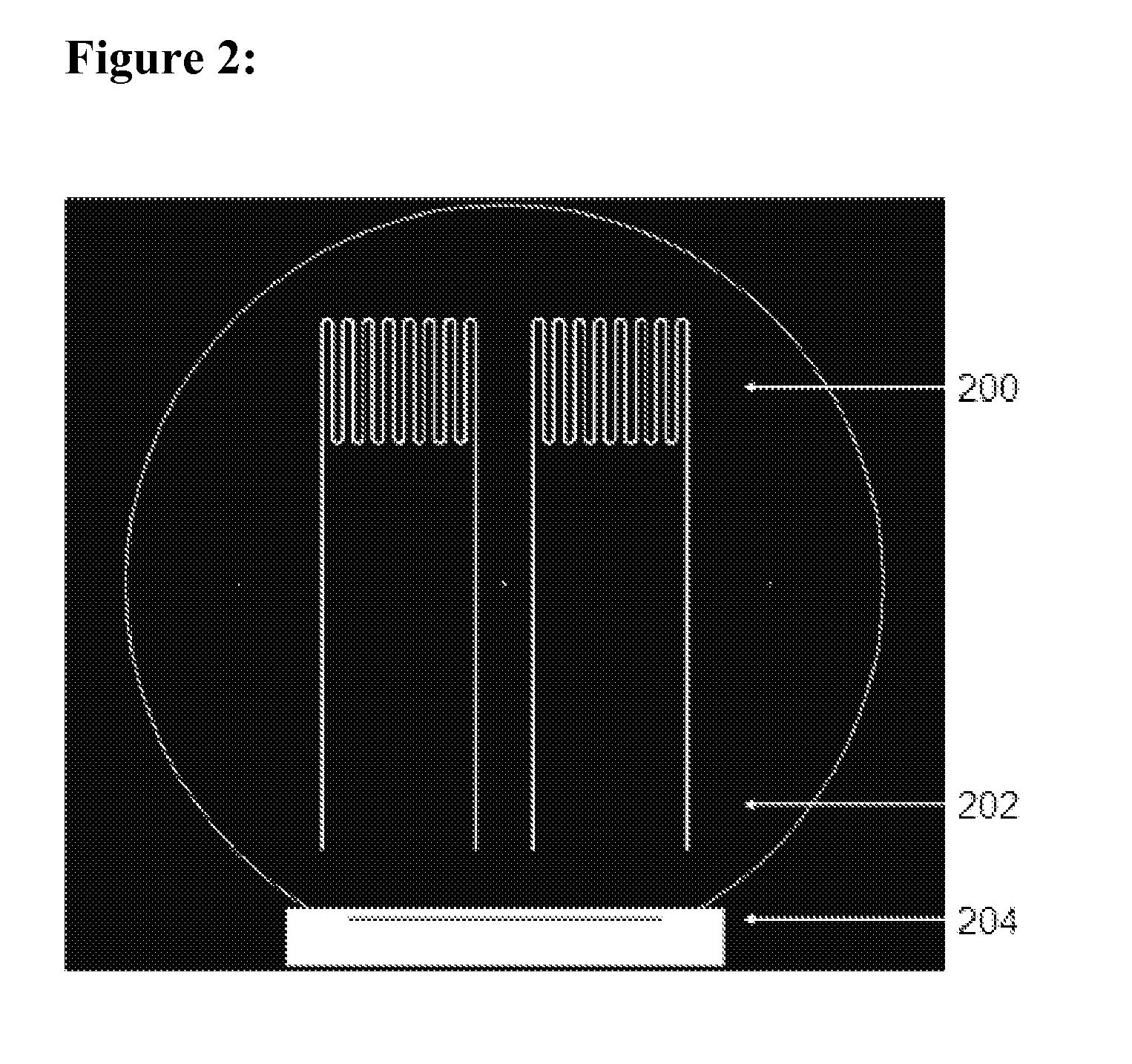

Microfabrication of high temperature microreactors

InactiveUS20120142118A1Stable isotopic compositional analysisGuaranteed uptimeHeating or cooling apparatusComponent separationMicroreactorMicrofabrication

Microreactors, methods of fabricating, and using such microreactors comprises a substrate having an outer periphery and composing two monolithic sections, each of said monolithic sections comprising two opposed main surfaces and one or more edges extending between the main opposed surfaces. One of the main surfaces from each of the monolithic sections are joined together at a substantially planar junction. The microreactor further comprises at least one microcapillary flow passage defined by surfaces within said substrate and having first and second ends. One or more inlets connect the outer periphery of said substrate with the first end of said microcapillary flow passage. One or more outlets connect the outer periphery of said substrate with the second end of said microcapillary flow passage, which may narrowingly taper. The substrate can be made from high purity fused silica. A metallic reagent and / or catalyst can be incorporated in the micro capillary passage.

Owner:CORNELL UNIVERSITY

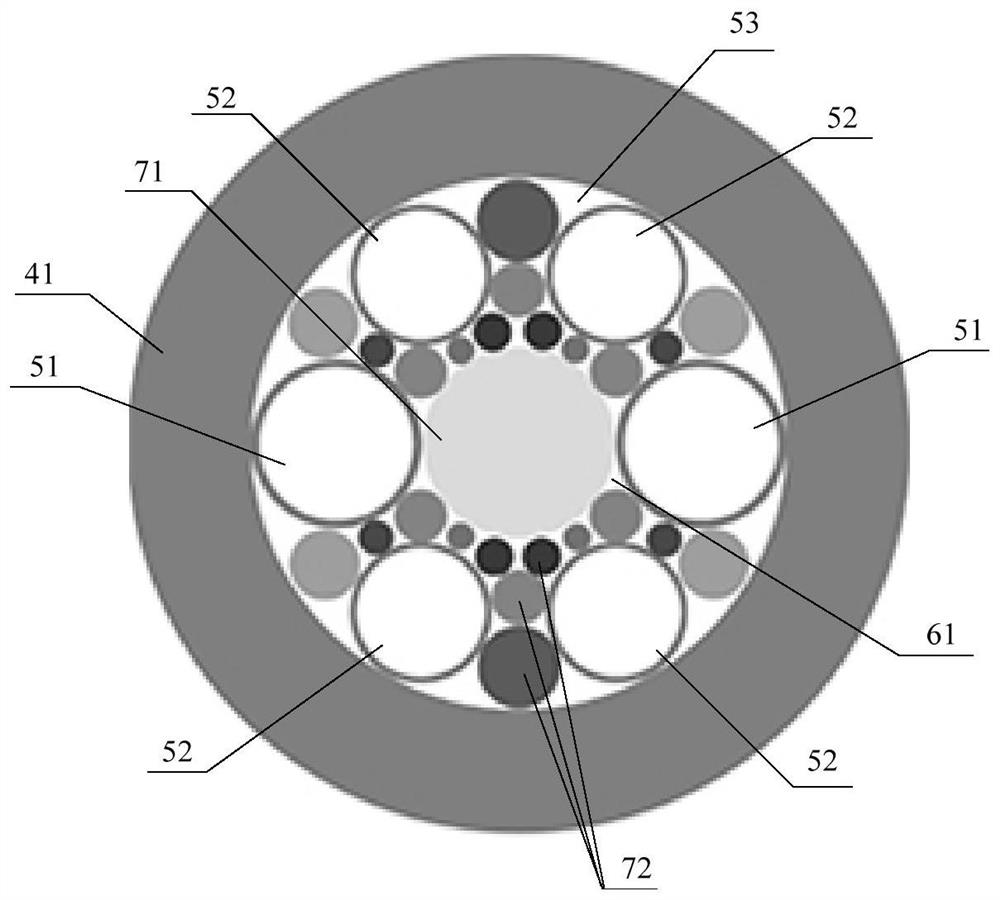

Anti-resonant hollow core optical fiber having multiple resonant layers

ActiveUS20200241200A1Narrow bandwidthLow efficiencyOptical fibre with multilayer core/claddingNanoopticsTransmission lossMaterials science

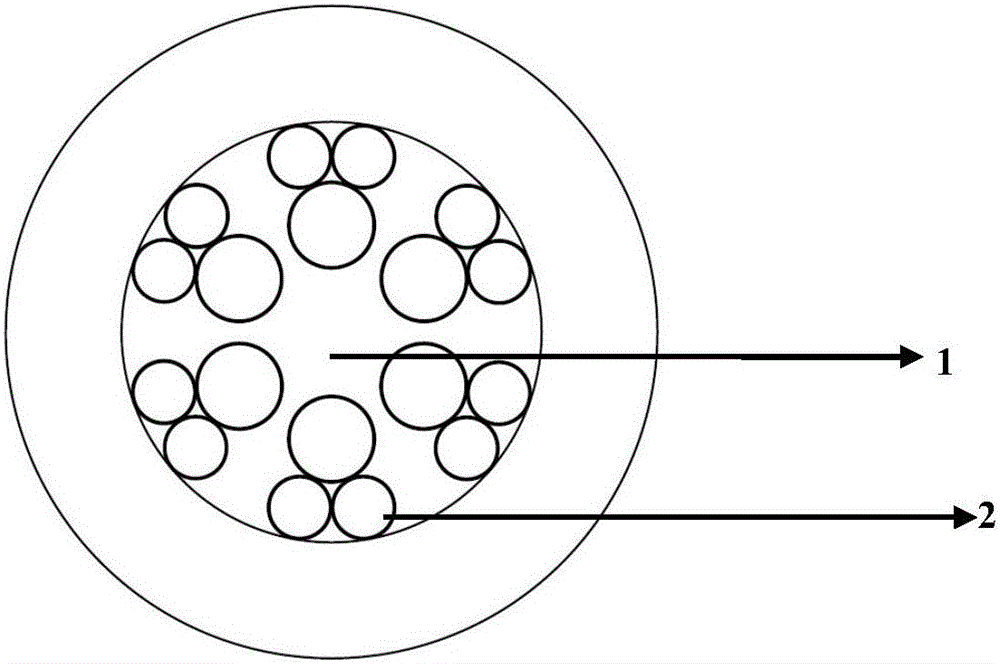

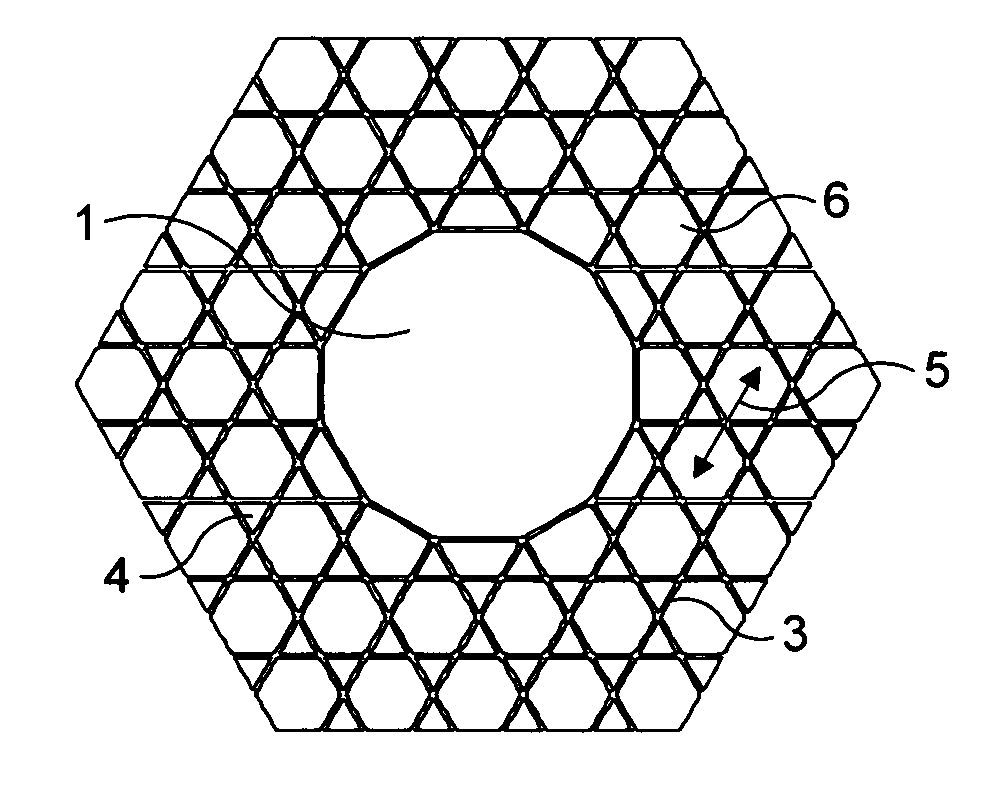

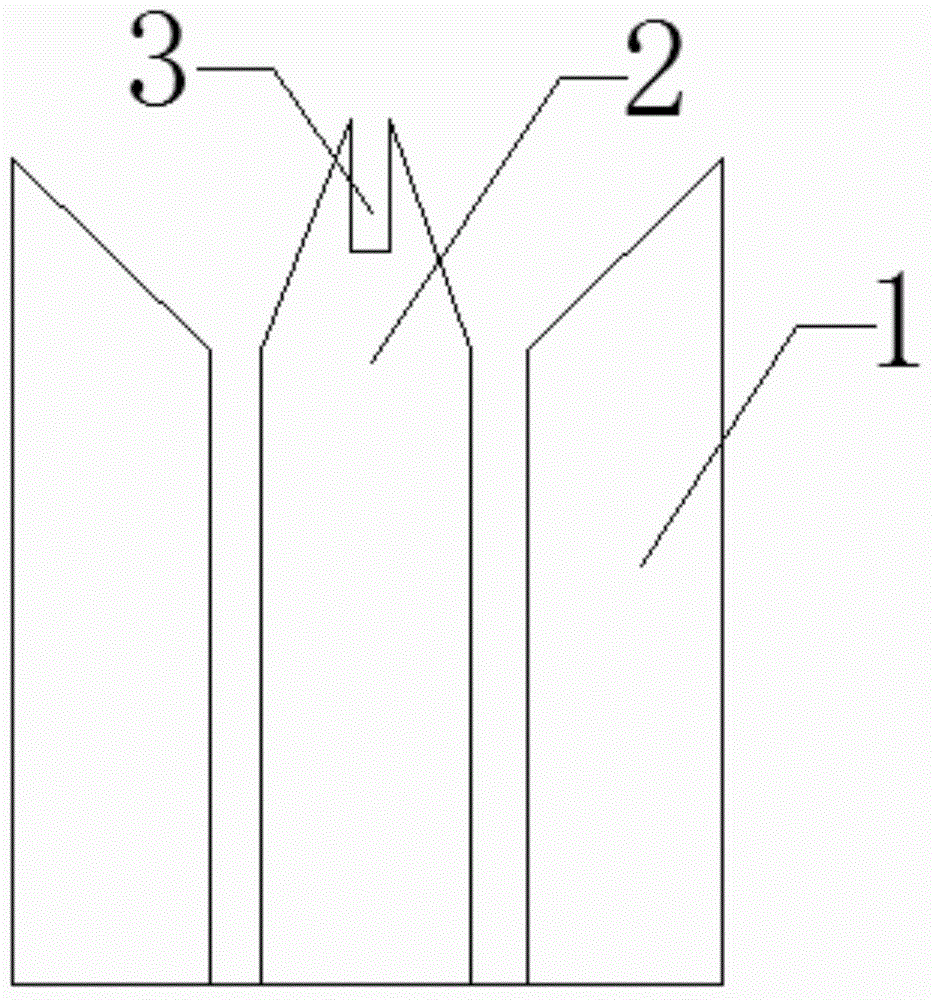

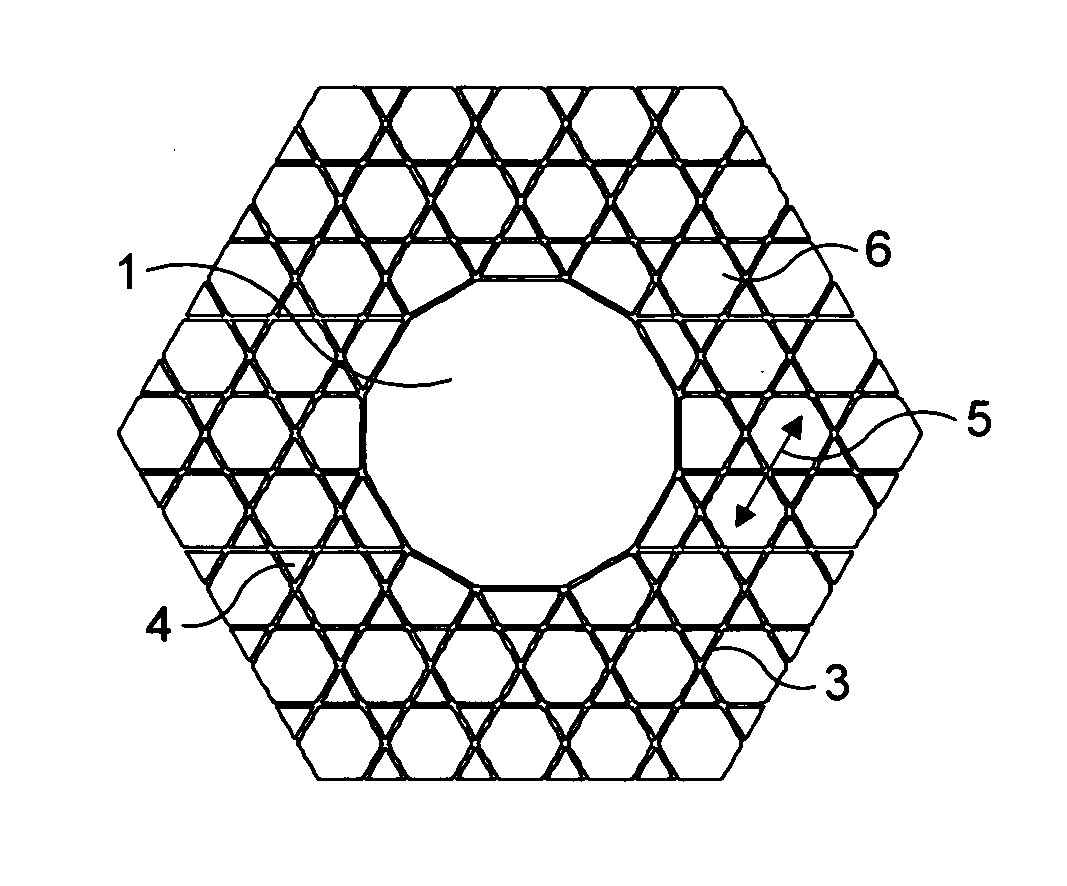

An anti-resonant hollow core optical fiber having multiple resonant layers. The optical fiber comprises a low-refractive index core region (1) and a high-refractive index cladding region. The high-refractive index cladding region comprises an inner cladding region (4) and an outer cladding region (5). The outer cladding region (5) clads the inner cladding region (4) and the core region (1). The inner cladding region (4) comprises a first anti-resonant layer (2) and a second anti-resonant layer (3), and the first anti-resonant layer (2) and the second anti-resonant layer (3) surround the core region (1); and the first anti-resonant layer (2) comprises several layers of microcapillary tubes, and the second anti-resonant layer (3) supports the first anti-resonant layer (2). The optical fiber adopts a double-cladding structure and uses two or more anti-resonant layers such that theoretically simulated loss is reduced to 0.1 dB / km, and has the features of ultralow transmission loss, wide spectral bandwidth, low bending loss, low transmission loss, high damage threshold and single-mode transmission.

Owner:BEIJING UNIV OF TECH

Hollow-core antiresonance photonic crystal fiber coupler and application thereof

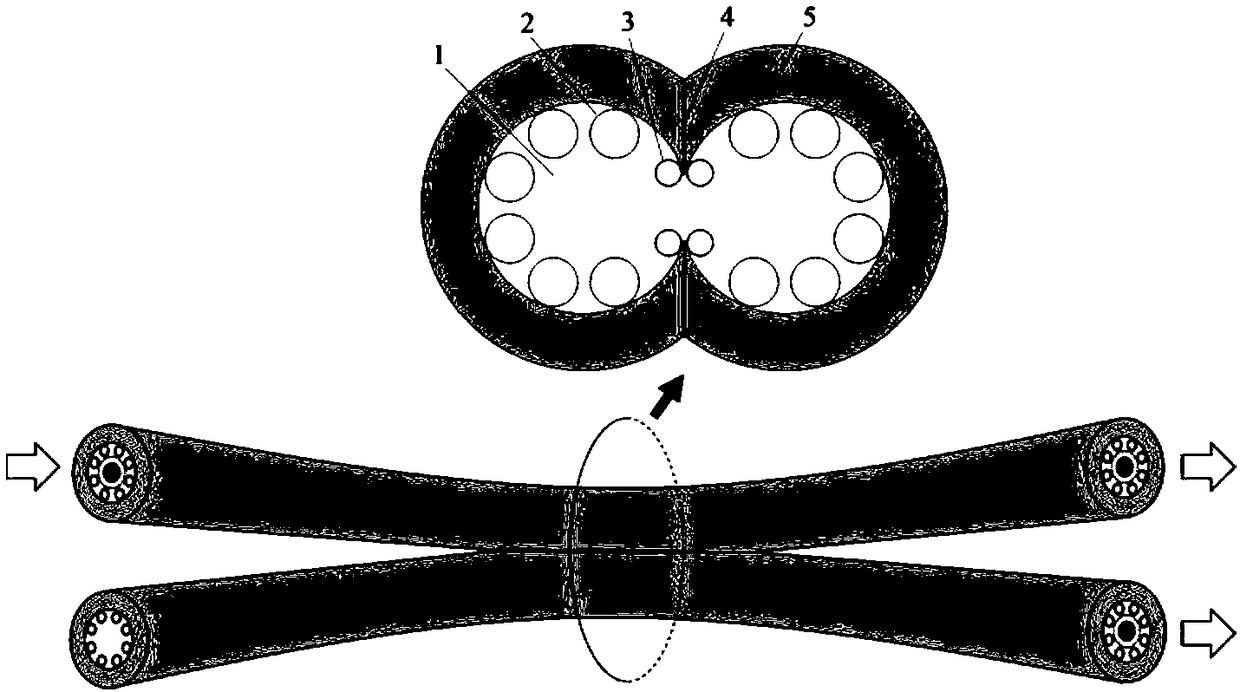

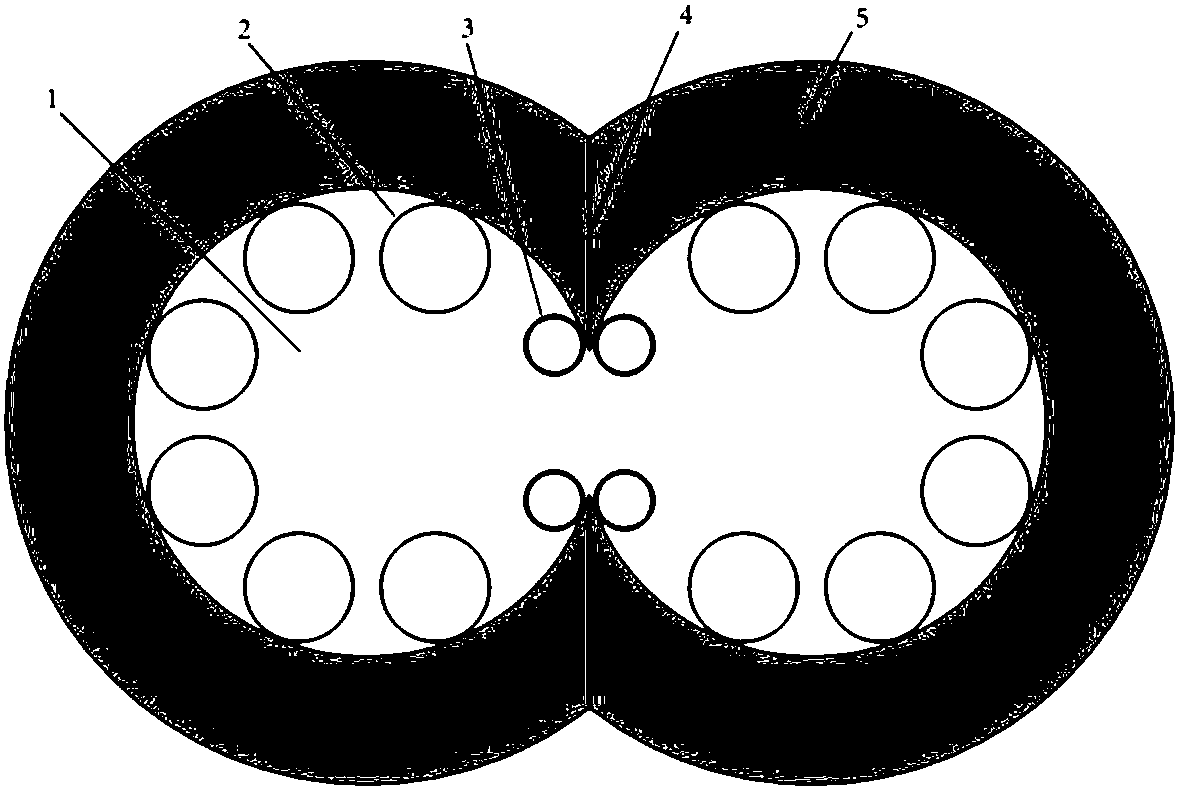

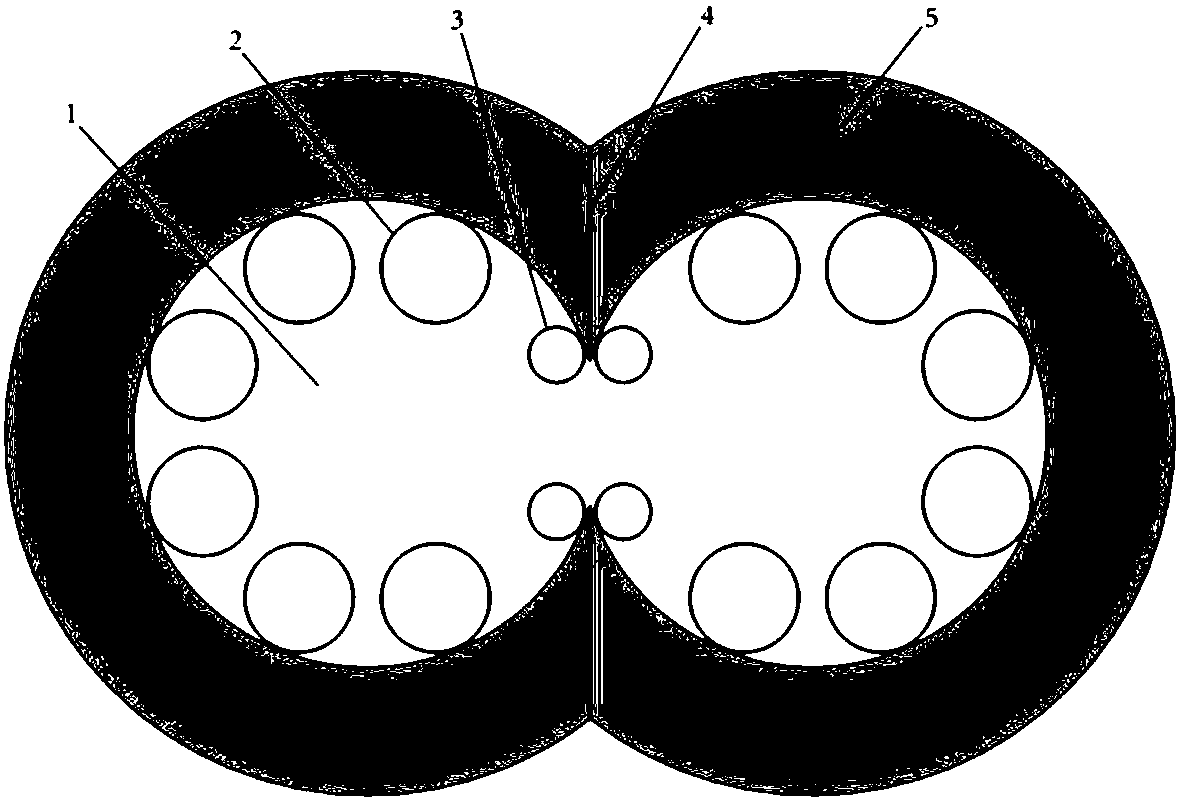

ActiveCN108549128AReduce splice lossImplement inputOptical fibre with multilayer core/claddingCoupling light guidesFiber couplerEngineering

The invention belongs to the technical field of fiber couplers, and particularly relates to a hollow-core antiresonance photonic crystal fiber coupler and application thereof. The fiber coupler is formed by two hollow-core antiresonance fibers with polished side faces. The basic structure of each hollow-core antiresonance fiber comprises a fiber core, a circle of micro-capillary inner covering layer around the fiber core and an outer covering layer covering the exterior of the micro-capillary inner covering layer. The polished faces of the hollow-core antiresonance fibers are arranged on the outer covering layer and are attached to each other and subjected to fusion or tapering, so a fiber coupler is manufactured. Before the tapering or during the tapering, the ring distance of two rings near the attached faces is reduced or increased, so the mode coupling of the fiber core of the two hollow-core antiresonance fibers is optimized. The fiber coupler is simple in design and highly practical, can be used for pulse laser, especially, full-fiber coupling and laser beam splitting of femtosecond laser and can be applied in a hollow-core fiber gyroscope to replace a solid fiber coupling module.

Owner:深圳市同昇光电有限公司

A micropump based on capillary action and its application method

InactiveCN102278293ASimplify complexityReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsCapillary fillPump chamber

The invention relates to a method for using a micropump based on capillary action, characterized in that the micropump is composed of a capillary pump chamber, a partition valve, a sample feeding micropipe and a liquid storage microchamber, wherein the capillary pump chamber is a micropipeline network The separation valve is a micropipe or microcavity connecting the capillary pump cavity and the micropipe for sampling; the micropipe for sampling is a micropipe between the inlet and the microcavity for the liquid storage, and the microcavity for the liquid storage is a culture chamber Or the reaction chamber, located at the end of the sampling micropipe. How to use the micropump: 1) Add samples or reagents into the injection port, so that it is driven by capillary force to fill the micropipe for sampling, and stop at the entrance of the microcavity for the liquid storage due to the action of the capillary microvalve; 2) In the capillary pump The driving liquid is added to the entrance of the chamber, and the driving liquid will fill the capillary pump chamber under the capillary force and compress the air in it to generate driving pressure, thereby dividing and pushing the sample or reagent into the microcavity of the micropipe for sampling. The provided micropumps can also be used in combination to realize quantitative micromixing, reaction or cell culture.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

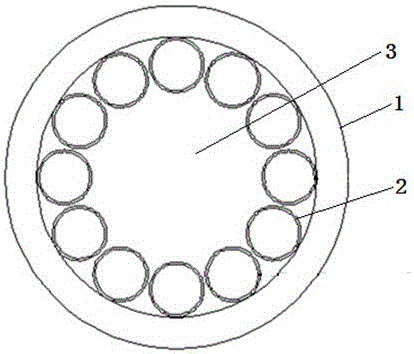

Hollow-core microstructure fiber with high damage threshold

InactiveCN106814421AHigh damage thresholdOptical fibre with multilayer core/claddingOptical waveguide light guideGuiding PrinciplesHigh energy

The invention relates to a hollow-core microstructure fiber with high damage threshold, which can transmit high-energy and high-power pulse laser. An inner cladding composed of 11 to 15 quartz micro capillaries arranged at intervals is arranged around the inner wall of a quartz glass tube of an outer cladding; the parts of the 11 to 15 quartz micro capillaries, in contact with the inner wall of the quartz glass tube, are fixed on the inner wall of the quartz glass tube in a welding manner; the middle parts of the 11 to 15 quartz micro capillaries, namely the innermost layers, are a fiber core area with low refractive index; and the fiber core area with low refractive index is filled with inert gas or air or vacuum. The hollow-core microstructure fiber has the beneficial effects that the inner cladding is composed of 11 to 15 mutually separated quartz micro capillaries, namely hollow-core microstructure fibers; and light is transmitted in a hollow-core fiber core by using an anti-resonance guide principle in the structure, so that most of the transmitted light energy exists in the fiber core with low refractive index, the damage threshold of the fiber is improved, and the foundation is laid for laser transmission with high energy and high power.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

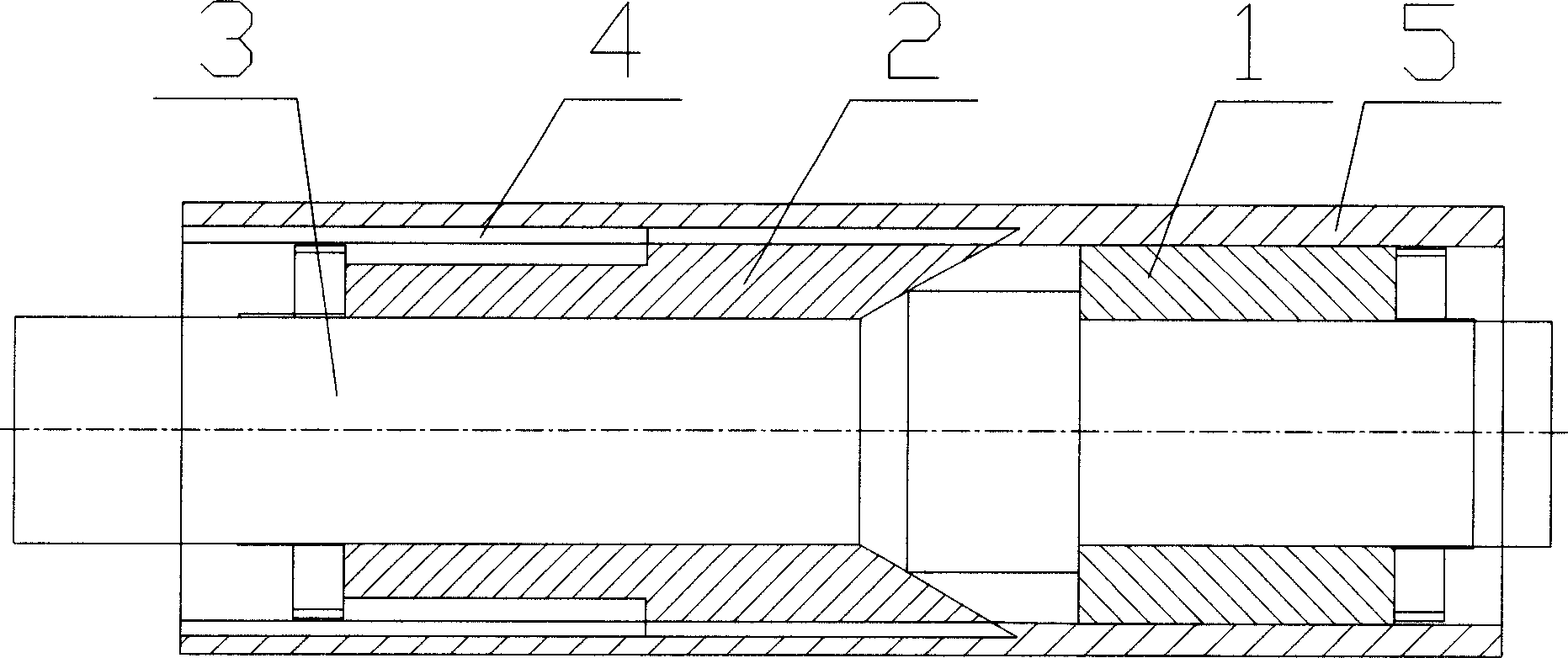

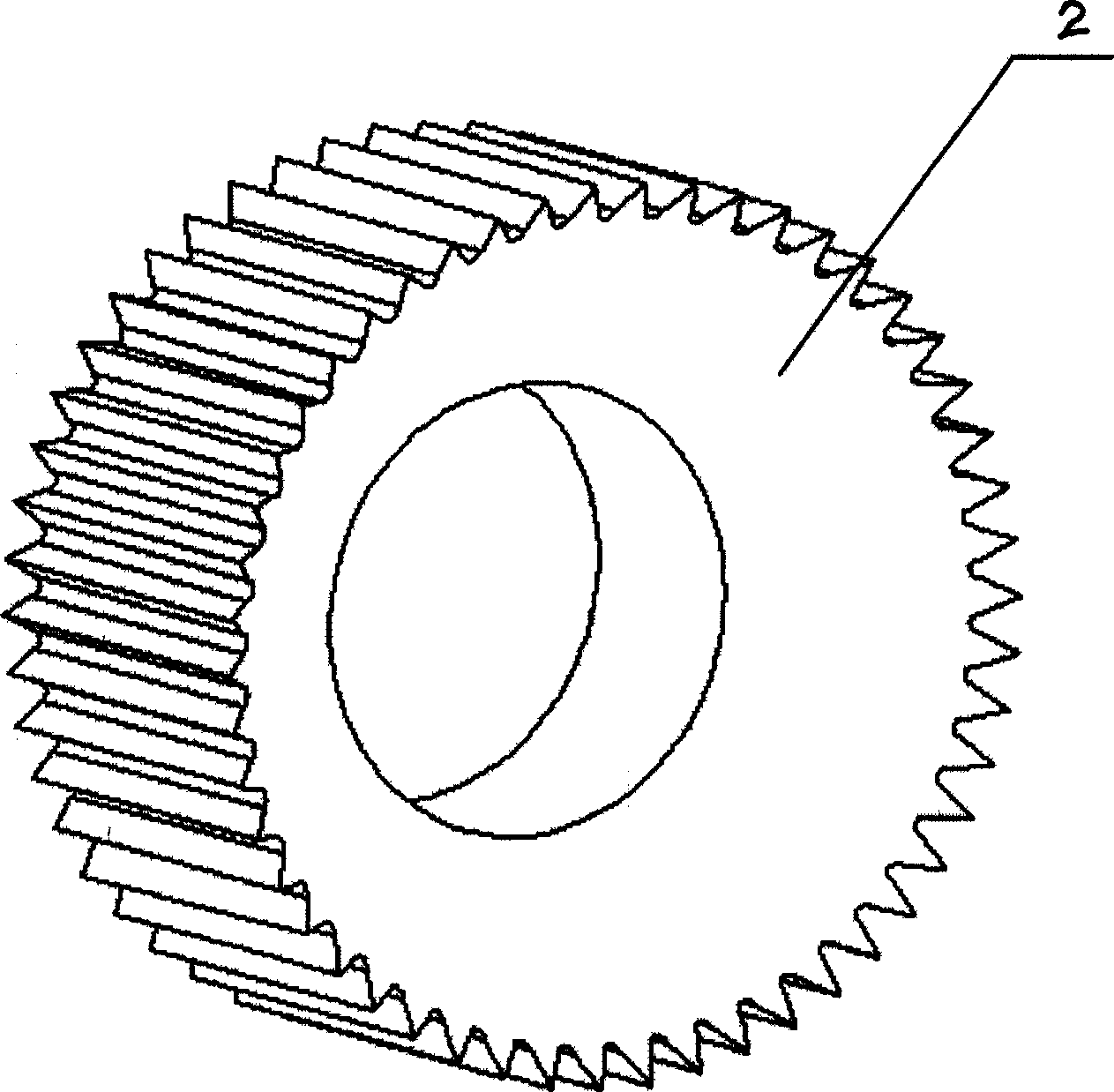

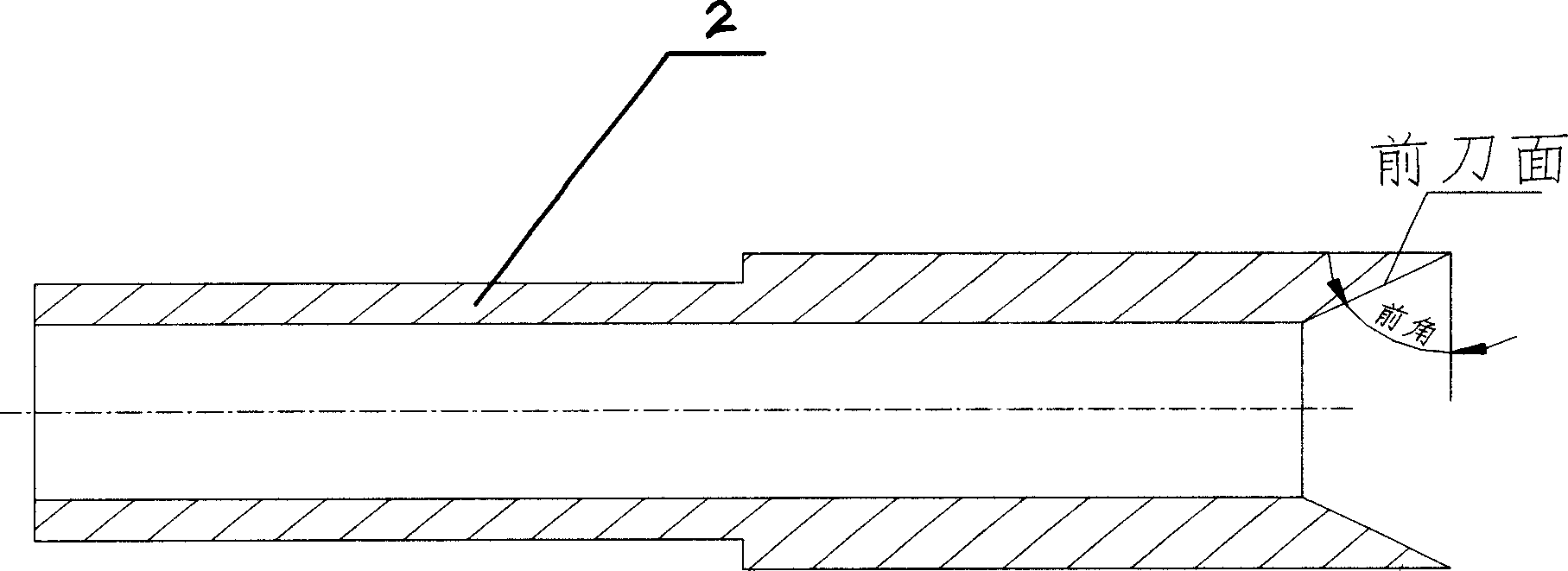

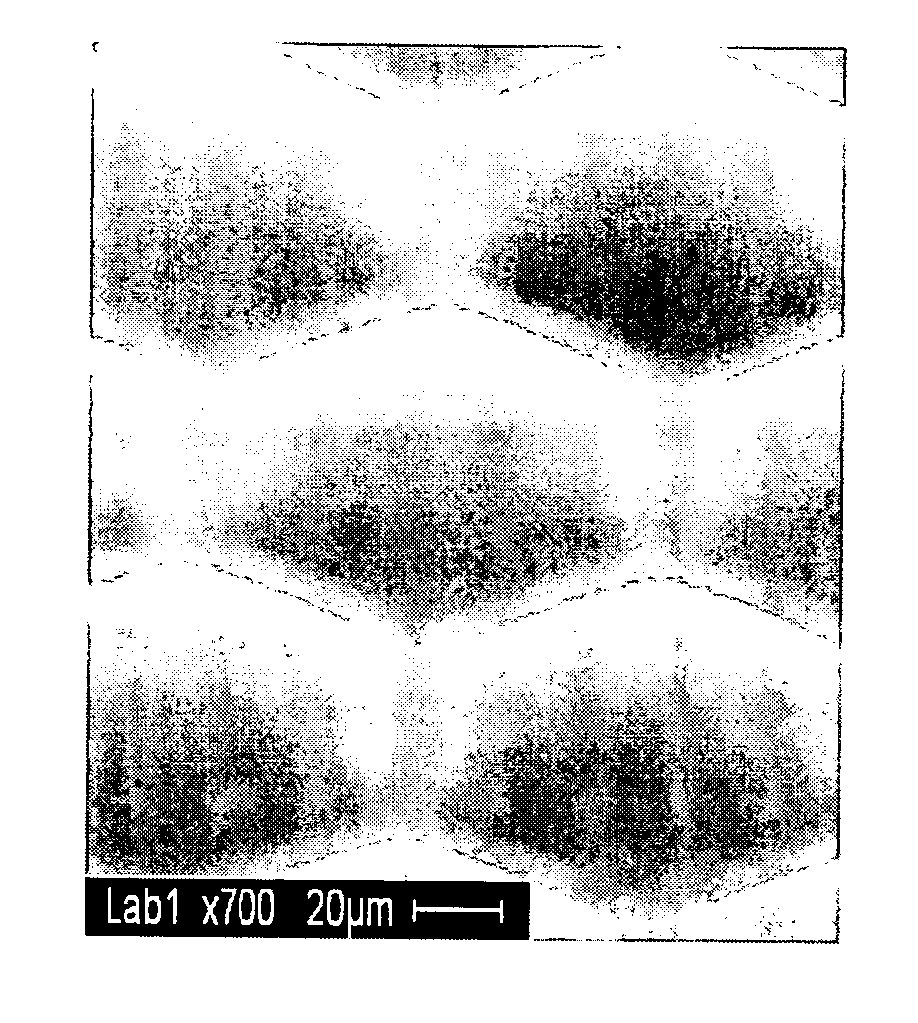

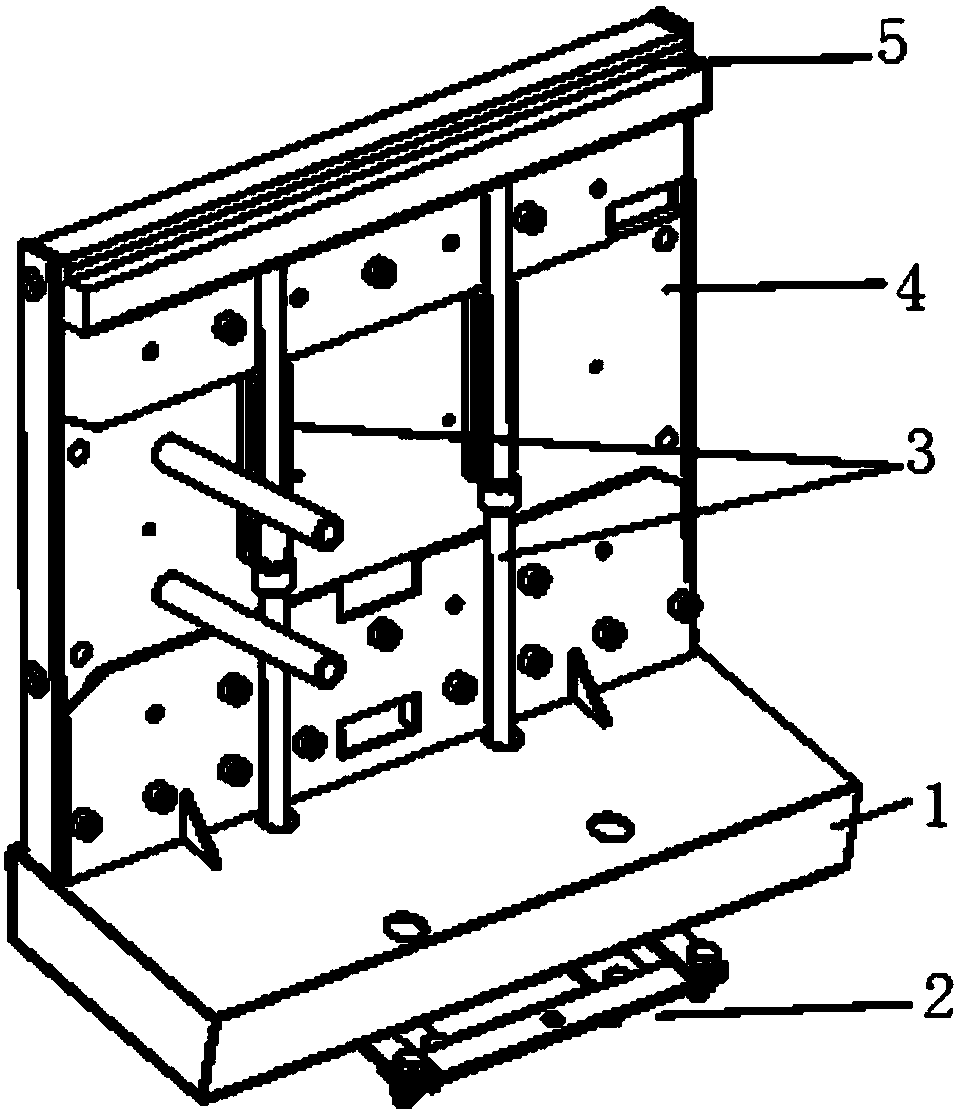

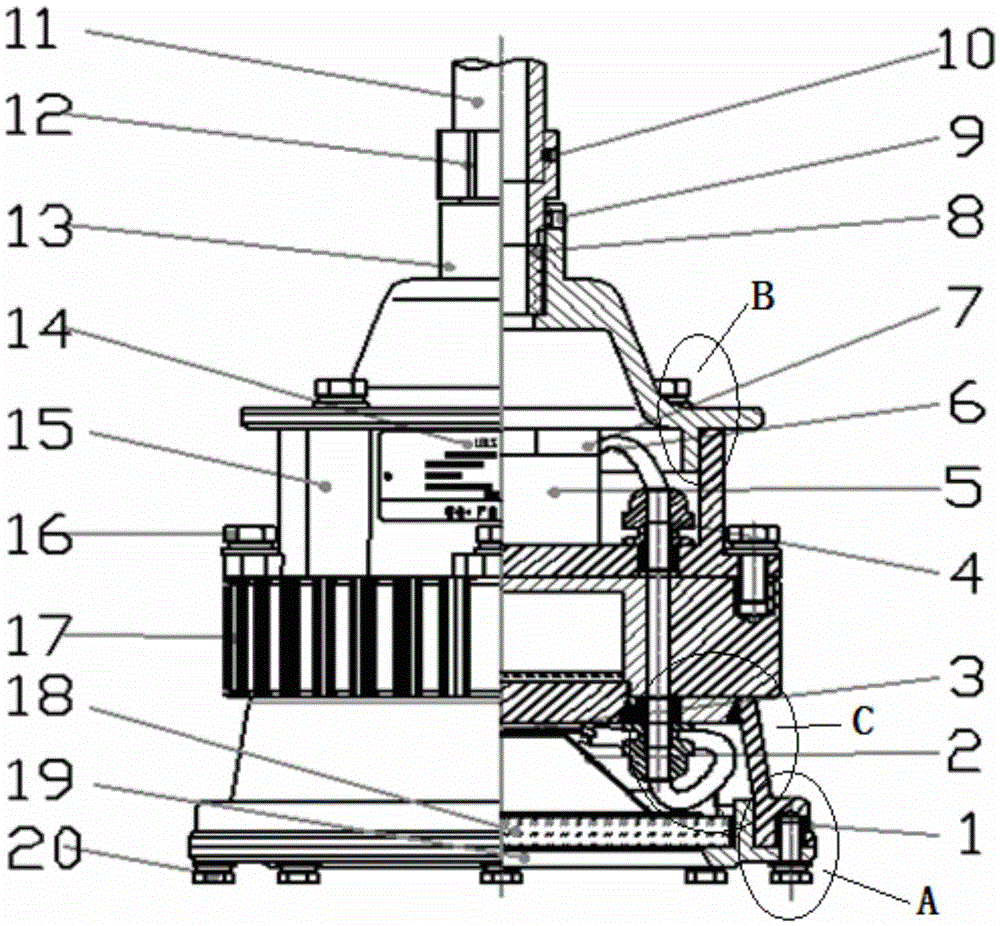

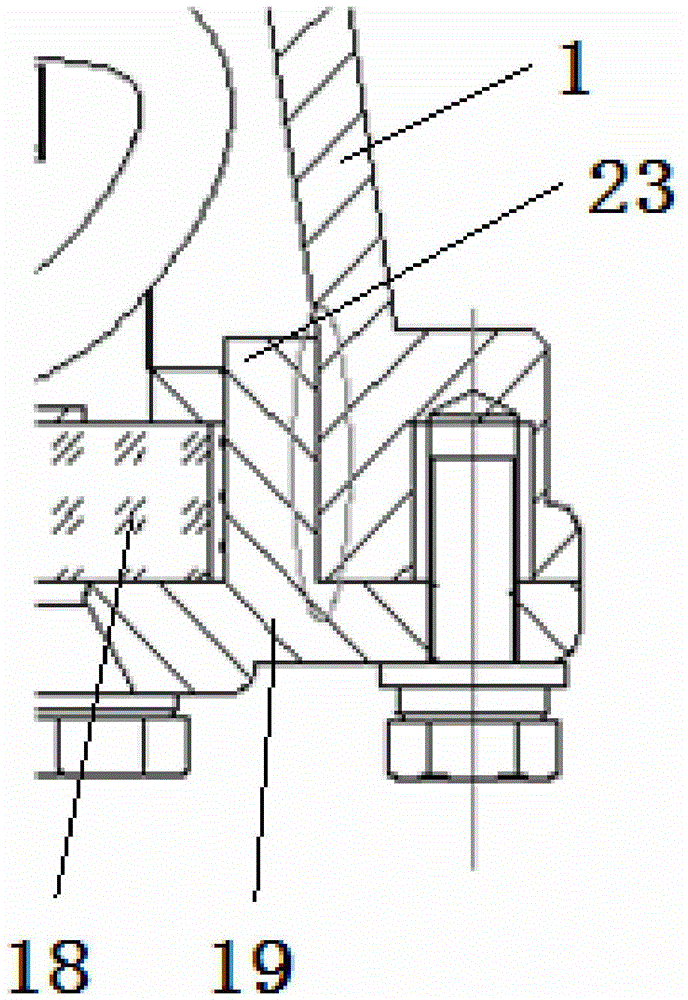

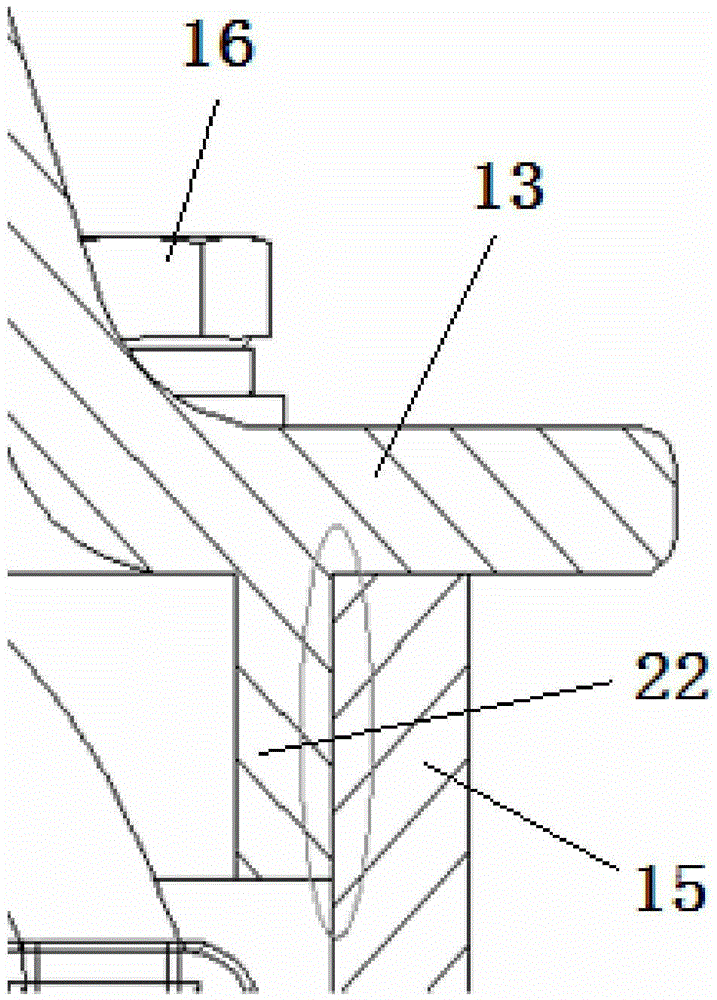

Producing device and its producing method for capillary tissue micro groove of heat pipe inner wall

InactiveCN1586777AReduce weightCapillary is reliableBroaching toolsBroaching machinesEngineeringHeat pipe

The device for making the micro capillary grooves in the inner wall of heat pipe mainly consists of positioning rod, cutter and pull rod. The positioning rod is mounted on one side surface of the pull rod, and the cutter is mounted on the other side surface of the pull rod. The present invention also relates to the method of making the micro capillary grooves in the inner wall of heat pipe with the said device. The making process features that the pull rod is drawn axially to drive the cutter to broach in the inner wall of the heat pipe base and the inner wall surface of the heat pipe base cracks to form capillary micro grooves. The improved capillary structure makes the heat pipe possess excellent heat transferring performance and lowers the production cost of heat pipe.

Owner:SOUTH CHINA UNIV OF TECH

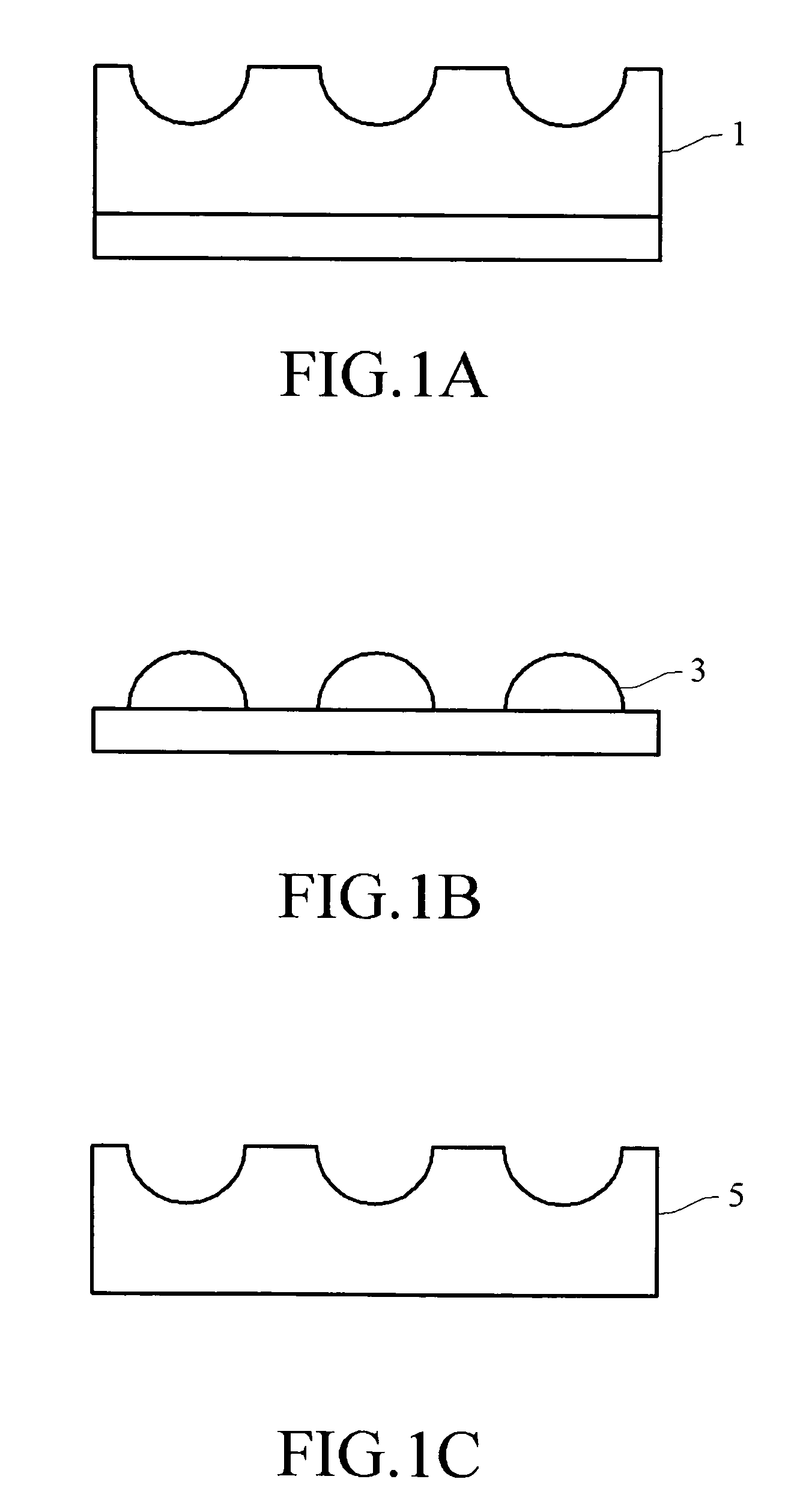

Method for fabricating a micro-lens mold and a concave micro-lens

A method for fabricating a micro-lens mold comprises forming a thick film on a substrate, patterning the thick film to form a micro-capillary, filling the micro-capillary with a heat curing glue liquor, rotating the substrate so that the liquid in the micro-capillary presents a circular arc shape as a micro-lens because of the surface tension of the material itself and the adhesion of the micro-capillary, and curing and shaping the heat curing glue liquor by the irradiation of a light source or by heating.

Owner:NAT CHUNG SHAN INST SCI & TECH

Hollow-core polarization-maintaining anti-resonance optical fiber and preparation method thereof

ActiveCN111812772ARealize the function of maintaining polarizationAdjustable birefringence valueGlass making apparatusOptical fibre with multilayer core/claddingCapillary TubingBirefraction

The invention discloses a hollow-core polarization-maintaining anti-resonance optical fiber and a preparation method thereof. The preparation method comprises the steps of: annularly and evenly distributing a circle of micro capillaries in a solid sleeve at intervals and closely attaching them to the wall of the solid sleeve, wherein the outer diameter of half or less of the micro capillaries is smaller than or larger than that of the rest micro capillaries, and a radial cross section of a middle hole defined by all the micro capillaries is oval; inserting an auxiliary capillary rod into eachof the two shaft ends of the middle hole, and inserting supporting capillary rods with different sizes into the spaces of the two shaft ends to obtain a stack body; drawing the intermediate slope partof the stack body, and actively controlling the pressure of each region; inserting the stack body intermediate obtained by drawing into a cladding sleeve to form an optical fiber preform; and performing optical fiber preparation on the optical fiber preform, and actively controlling the pressure of each region in the optical fiber preparation process. The preparation method has the advantages that the prepared optical fiber is low in preparation cost, low in loss, low in dispersion and fast in transmission, and the birefringence value can be controlled and adjusted through air pressure in thepreparation process.

Owner:艾菲博(宁波)光电科技有限责任公司

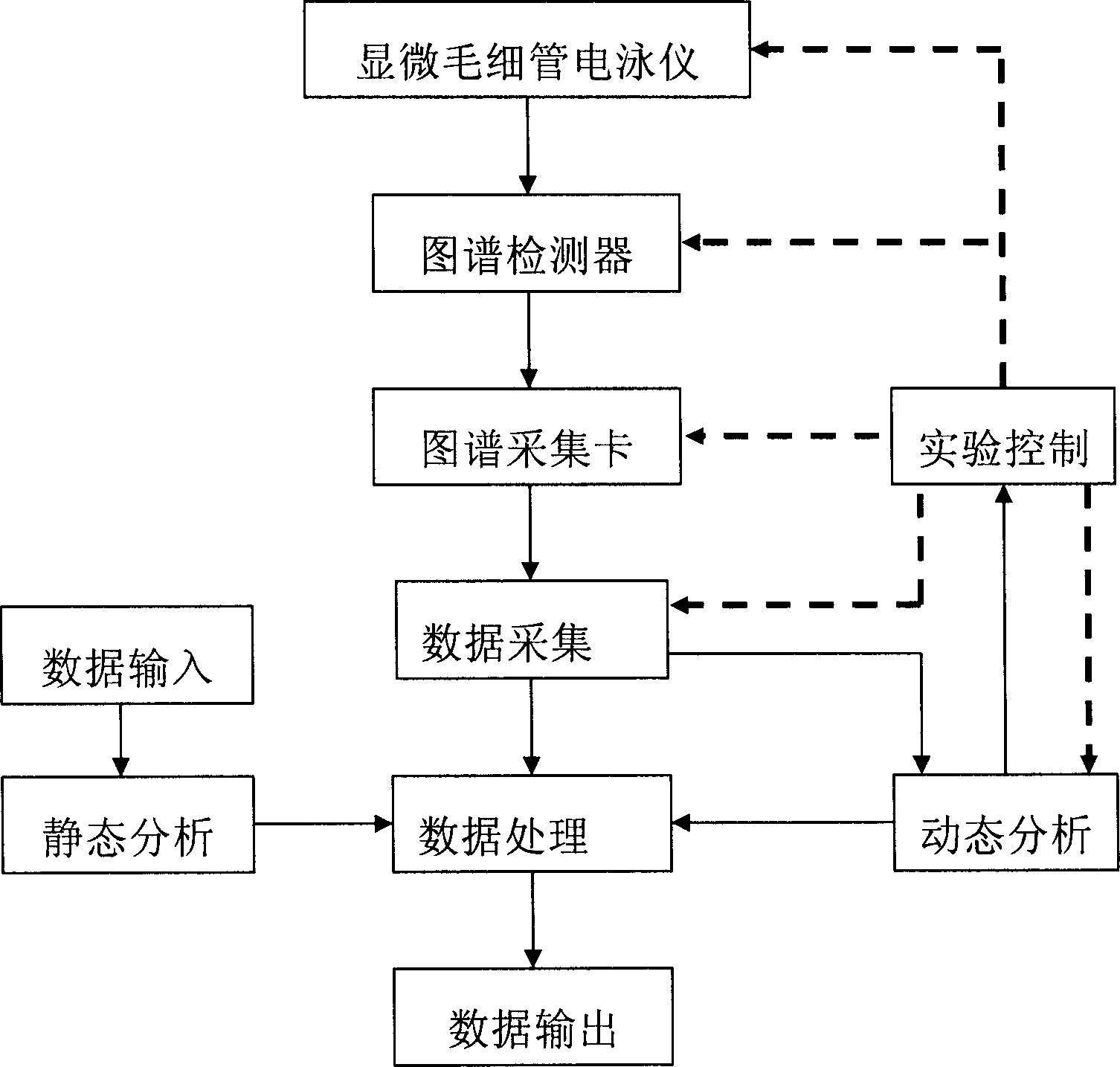

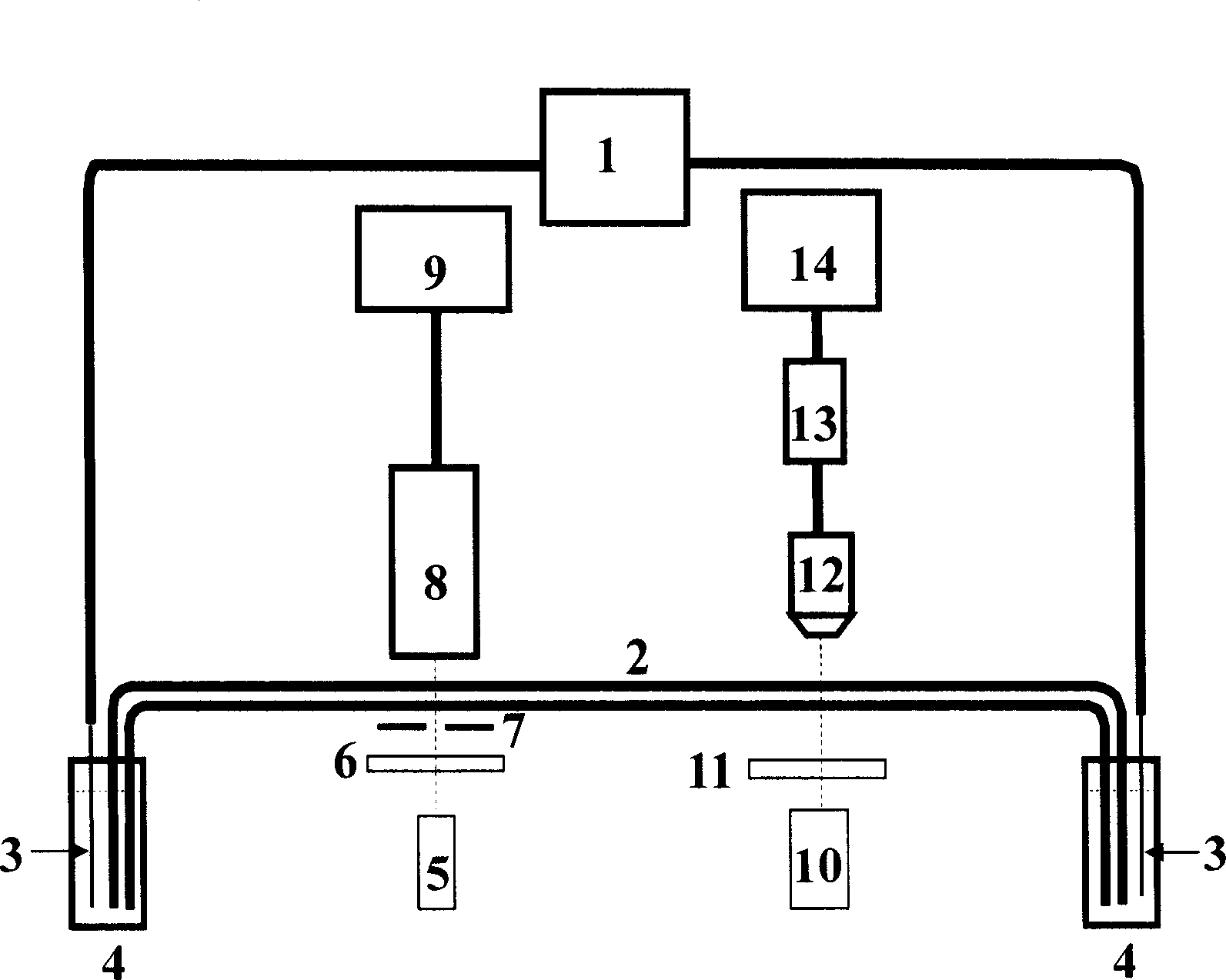

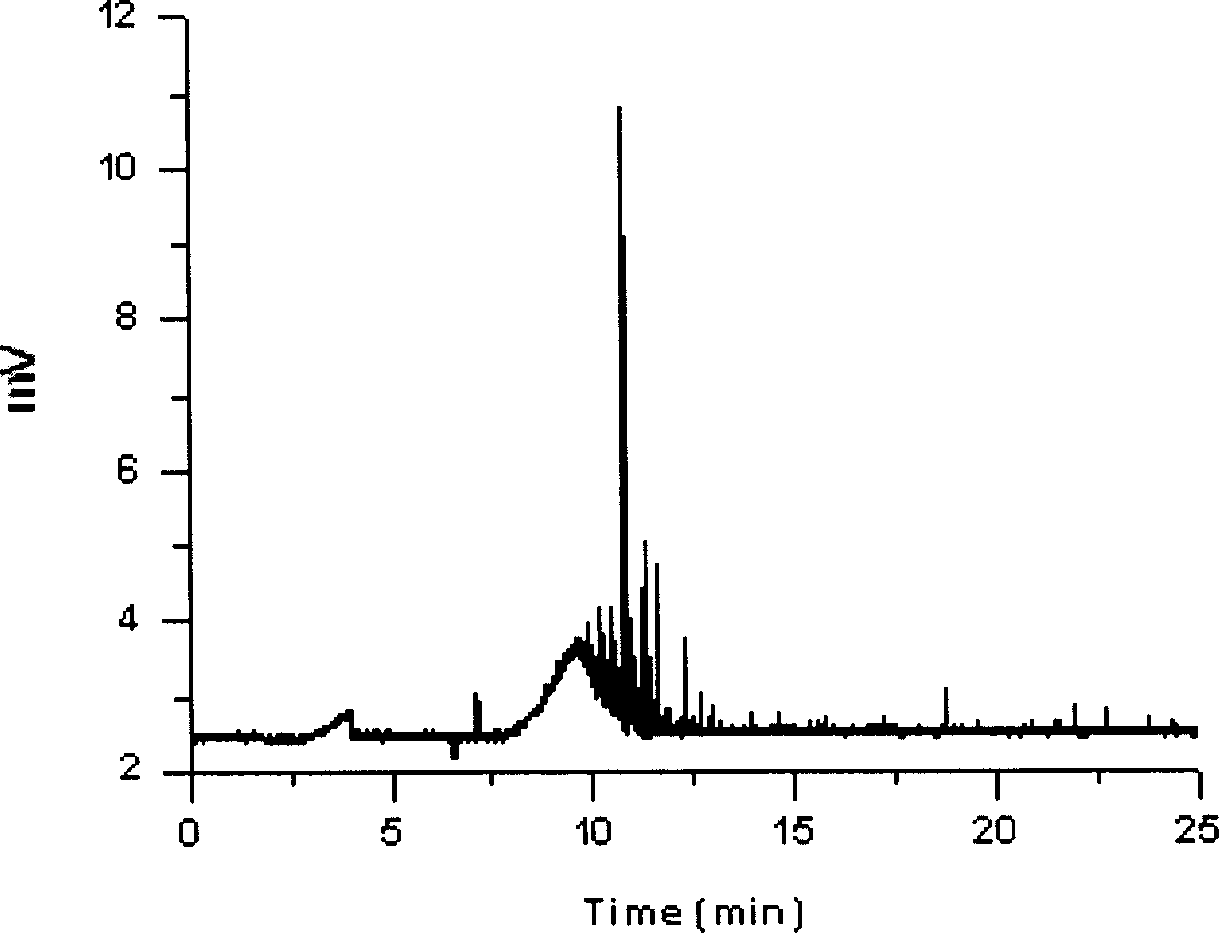

Micro-capillary electropheresis apparatus

InactiveCN1811399AIntuitive and more convincing observation resultsMaterial analysis by electric/magnetic meansMaterial analysis by optical meansCapillary electrophoresisCollection system

The present invention relates to a microscope capillary electrophoresis apparatus. It is mainly formed from capillary electrophoresis system, electrophoresis pattern collection system and image collection system, in which the capillary electrophoresis system includes two liquid bottles, capillary tube and high-voltage power supply, the electrophoresis pattern collection system includes light source and photoelectric converter, and the image collection system includes a microscope light source, a microscope, an image collector and an image display processor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Immunoassays, methods for carrying out immunoassays, immunoassay kits and method for manufacturing immunoassay kits

ActiveUS20130011913A1Increase contactMeasurable differenceBioreactor/fermenter combinationsLiquid surface applicatorsImmunoassay techniqueChemistry

The invention relates to immunoassays, methods for carrying out immunoassays, immunoassay kits and methods for manufacturing immunoassay kits. In particular, the invention has relevance to capillary (especially microcapillary) immunoassay technology.

Owner:CAMBRIDGE ENTERPRISE LTD

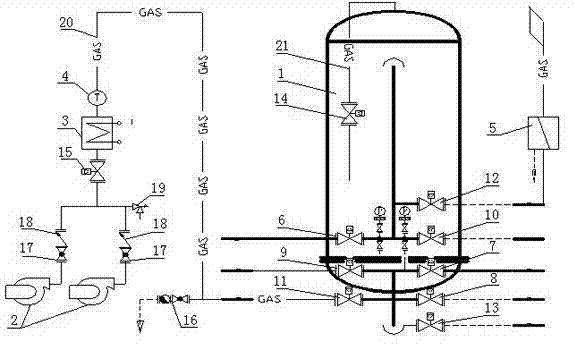

Regenerating method of active carbon filter

ActiveCN102228751AMeet environmental protection requirementsRestore snap functionSolid sorbent liquid separationLoose filtering material filtersInternal pressureActivated carbon filtration

The invention provides a regenerating method of an active carbon filter, which comprises the following steps of: (1), discharge of water: controlling a liquid level to be 200-400mm above an active carbon filtering layer; (2), air scrubbing: removing pollutants on surfaces of active carbon particles; (3), backwashing: removing the pollutants on the surfaces of the active carbon particles through backwashing; (4) discharge of water: discharging all water in equipment; (5), drying of active carbons: controlling the temperature between 115 DEG C and 120 DEG C, and blowing pollutant scraps and powdery active carbon out of the active carbon filter; (6), rinsing of the active carbon: rinsing and cleaning the pollutant scraps, dust and the powdery active carbon; and (7), positive rinsing. When the method provided by the invention is adopted, acid and alkaline wastewater is not produced, and the requirement for environment friendliness is met; as dry high-temperature hot air is adopted, water in the active carbon particles can be boiled and evaporated, an inner pressure can be produced, and micro capillary holes of the active carbon can be unblocked and recovered to restore the adsorption function; moreover, the dry high-temperature hot air can be used for killing organic lives and blowing the organic lives out of the equipment to realize complete cleaning.

Owner:青岛天兰环境股份有限公司

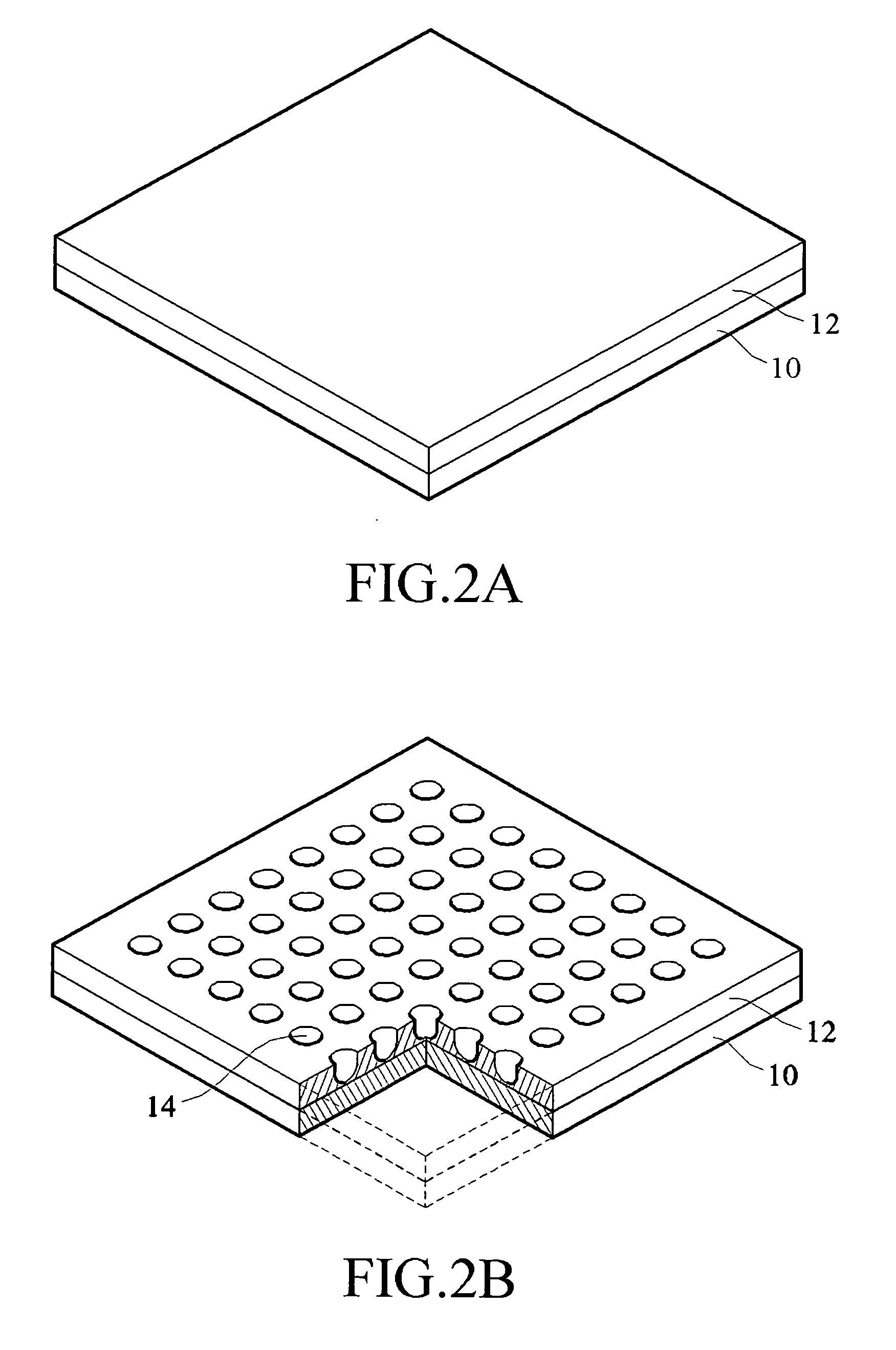

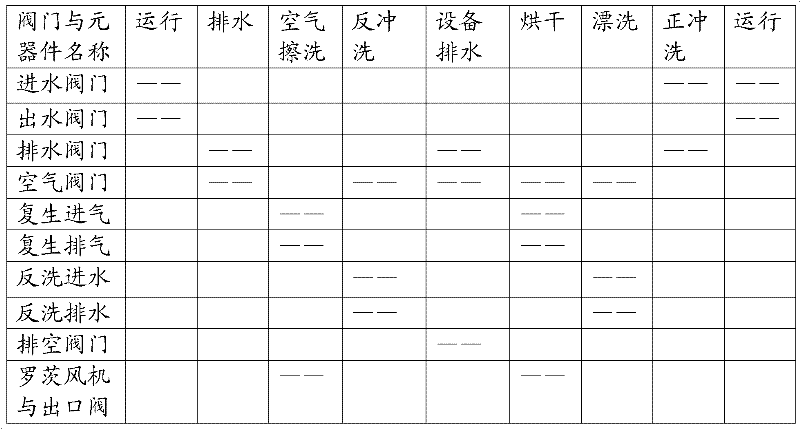

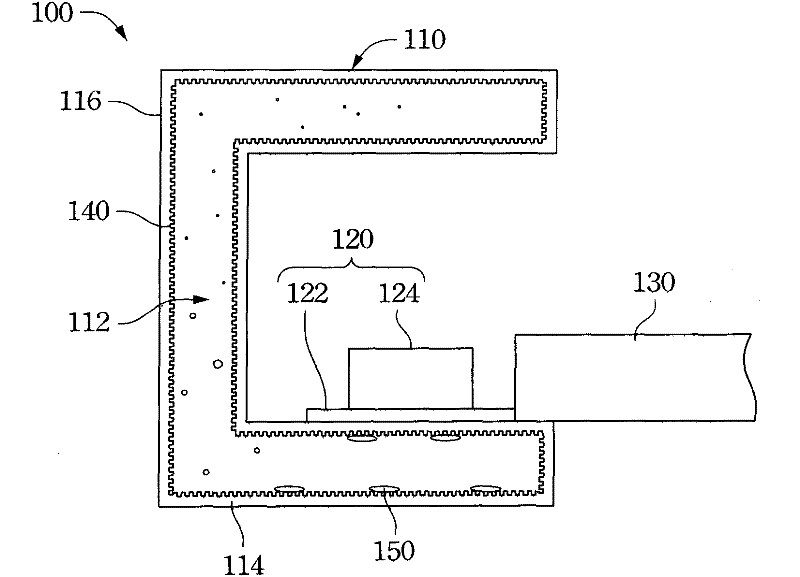

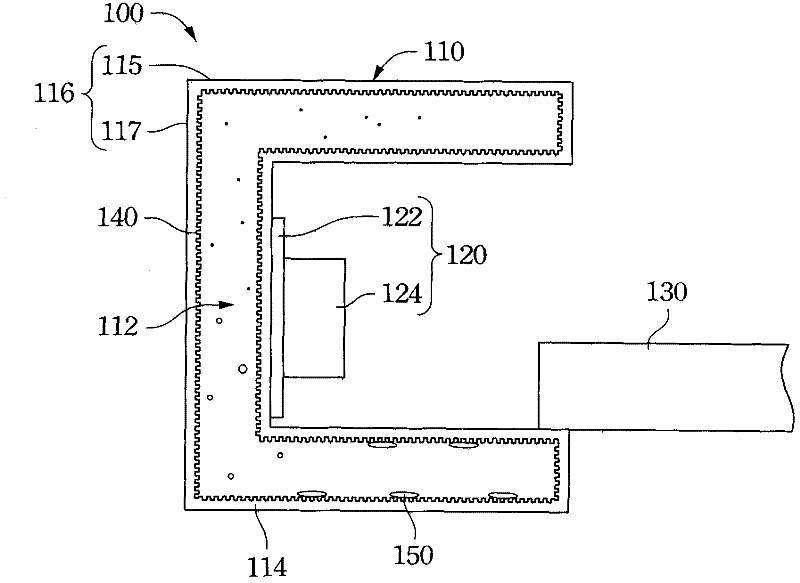

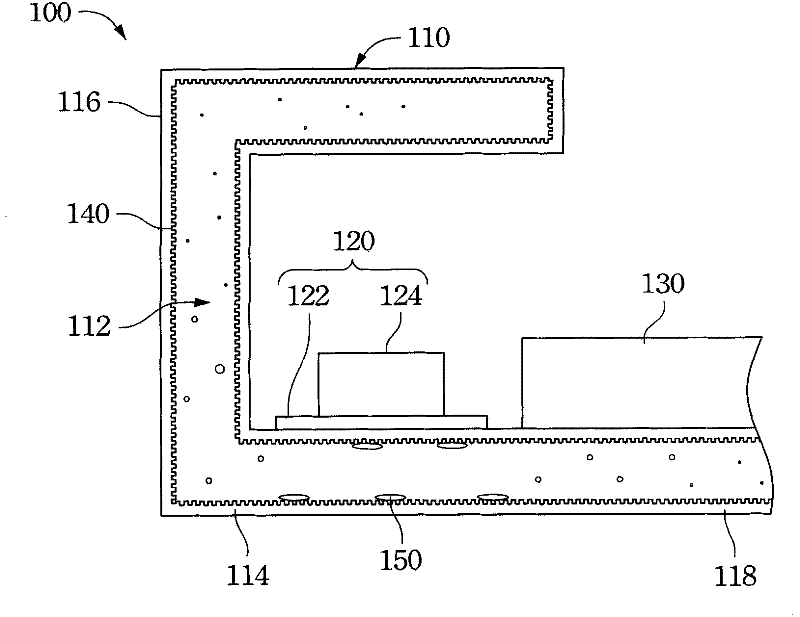

Backlight module

InactiveCN102352981AUniform and efficient removalPrevent removalLighting heating/cooling arrangementsLight fasteningsOptoelectronicsMicro capillary

A backlight module comprises a support provided with a cavity, a light source arranged on the support, a micro capillary structure formed at the surface of the cavity and a fluid arranged in the cavity.

Owner:AU OPTRONICS CORP

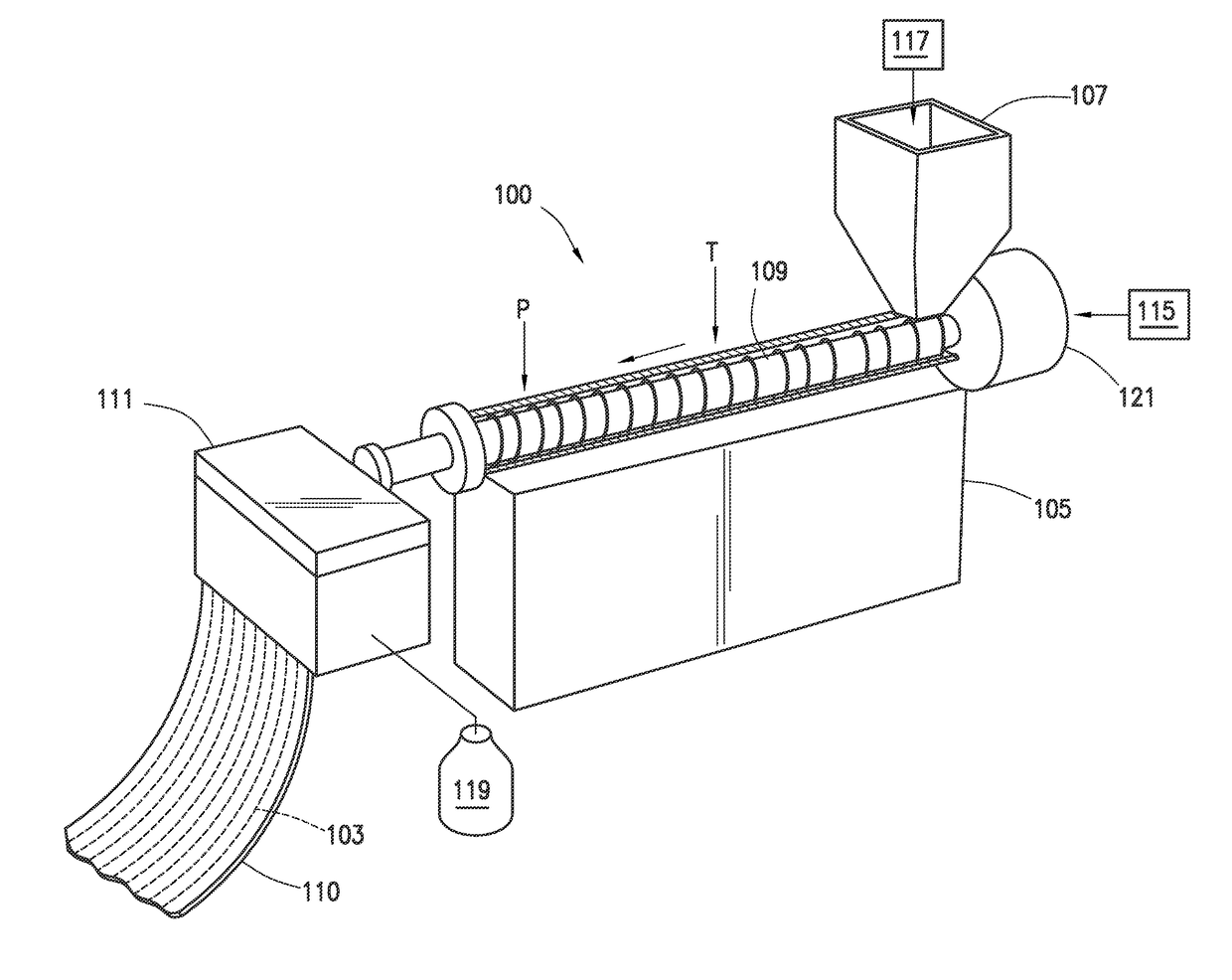

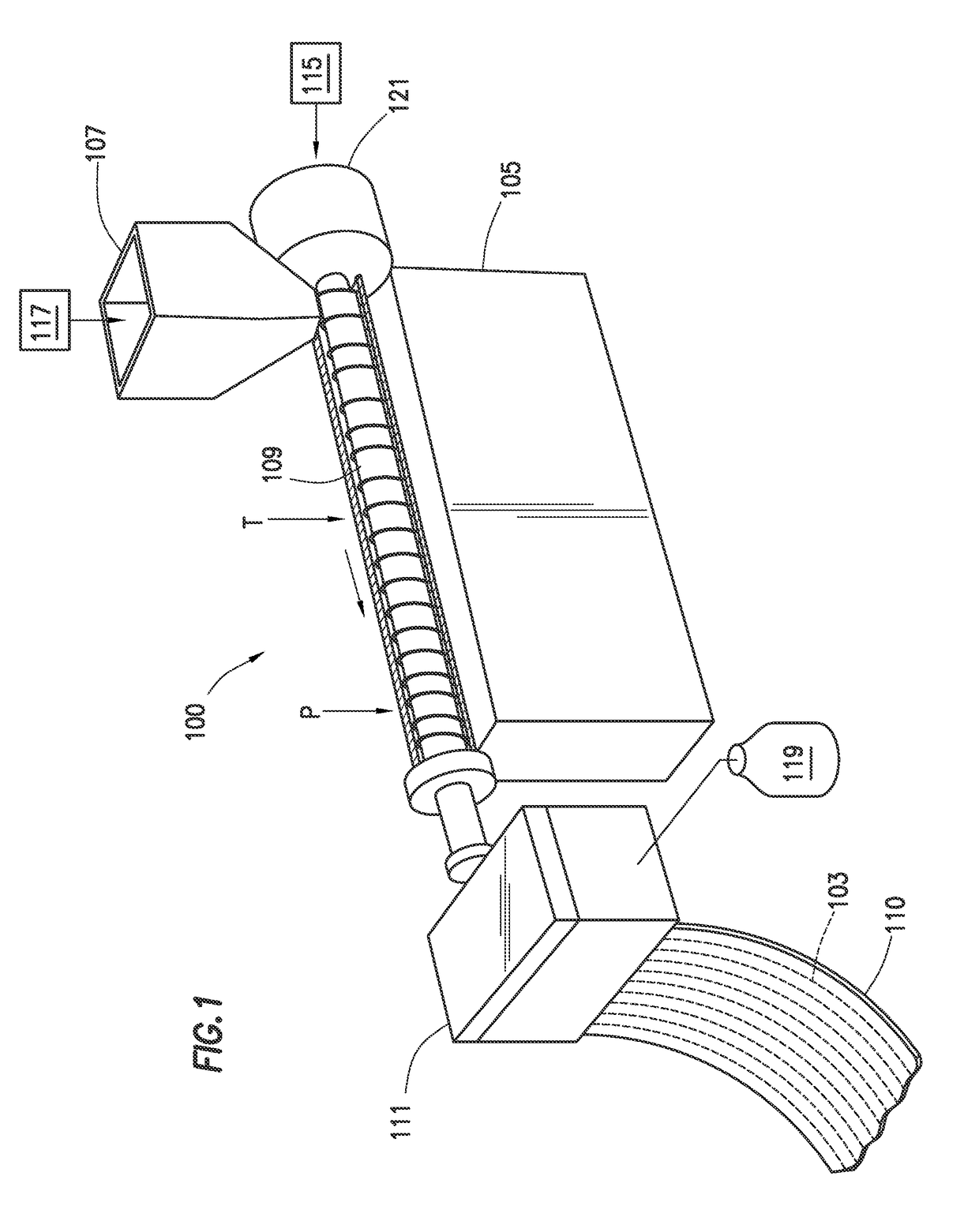

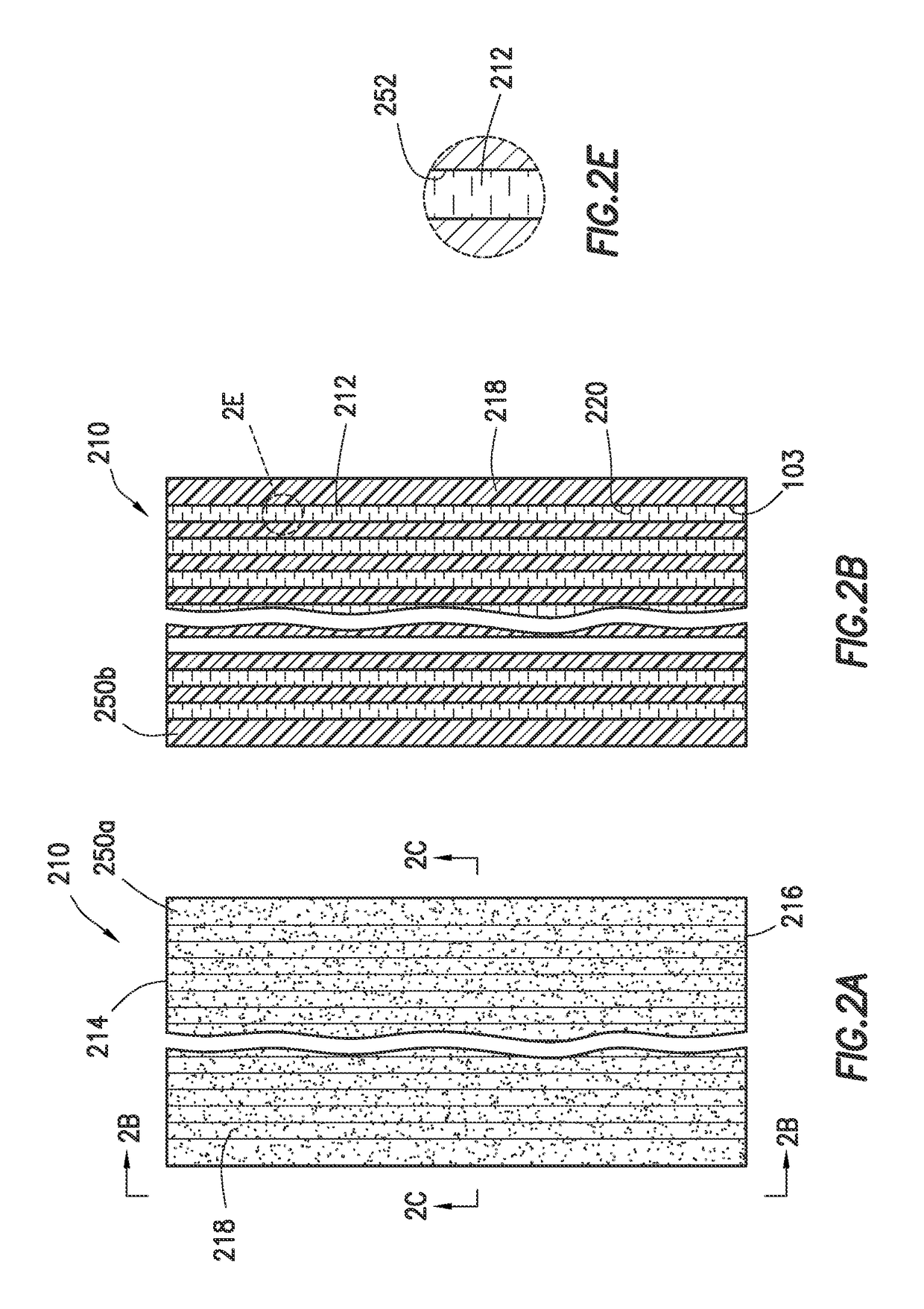

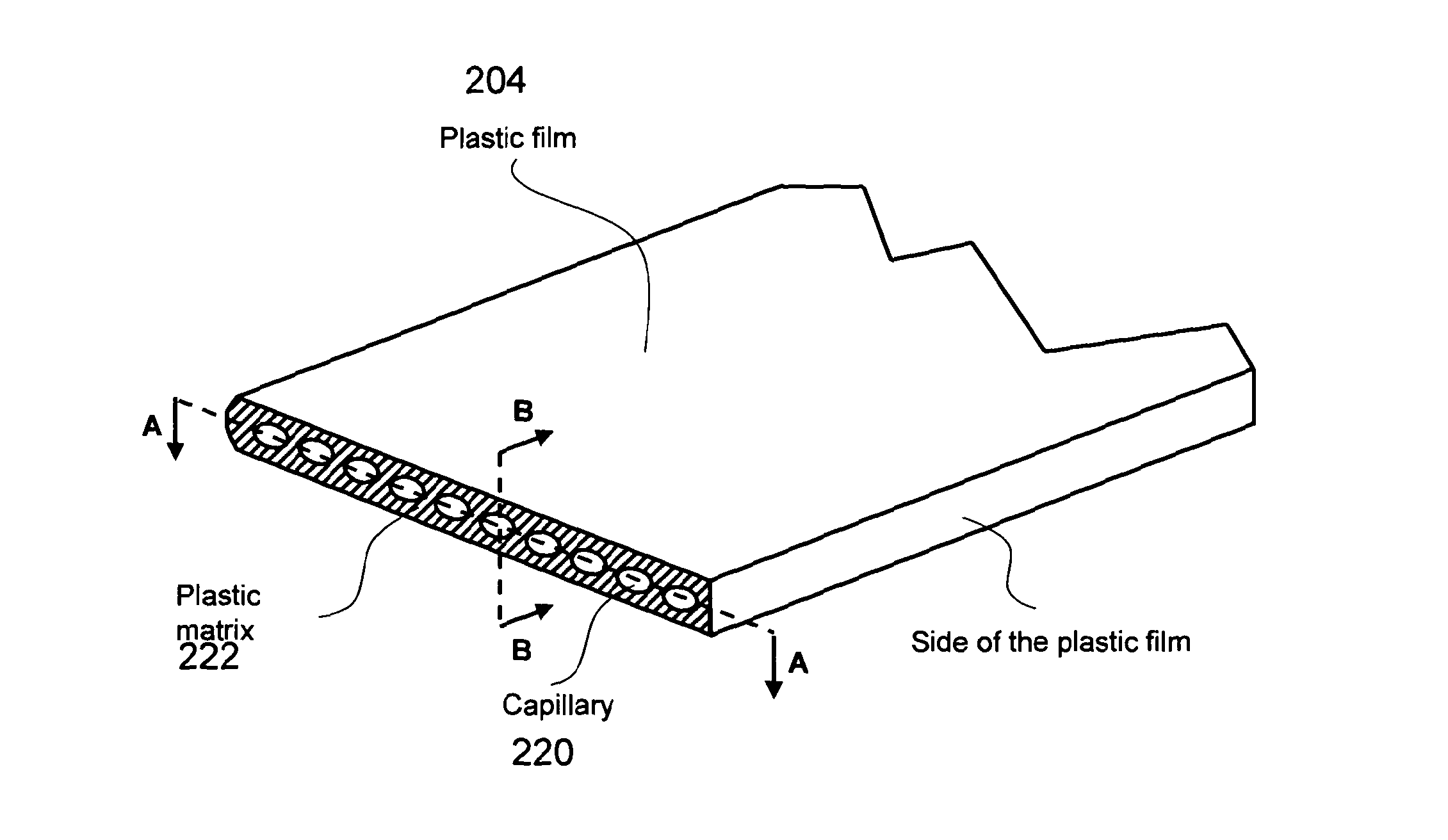

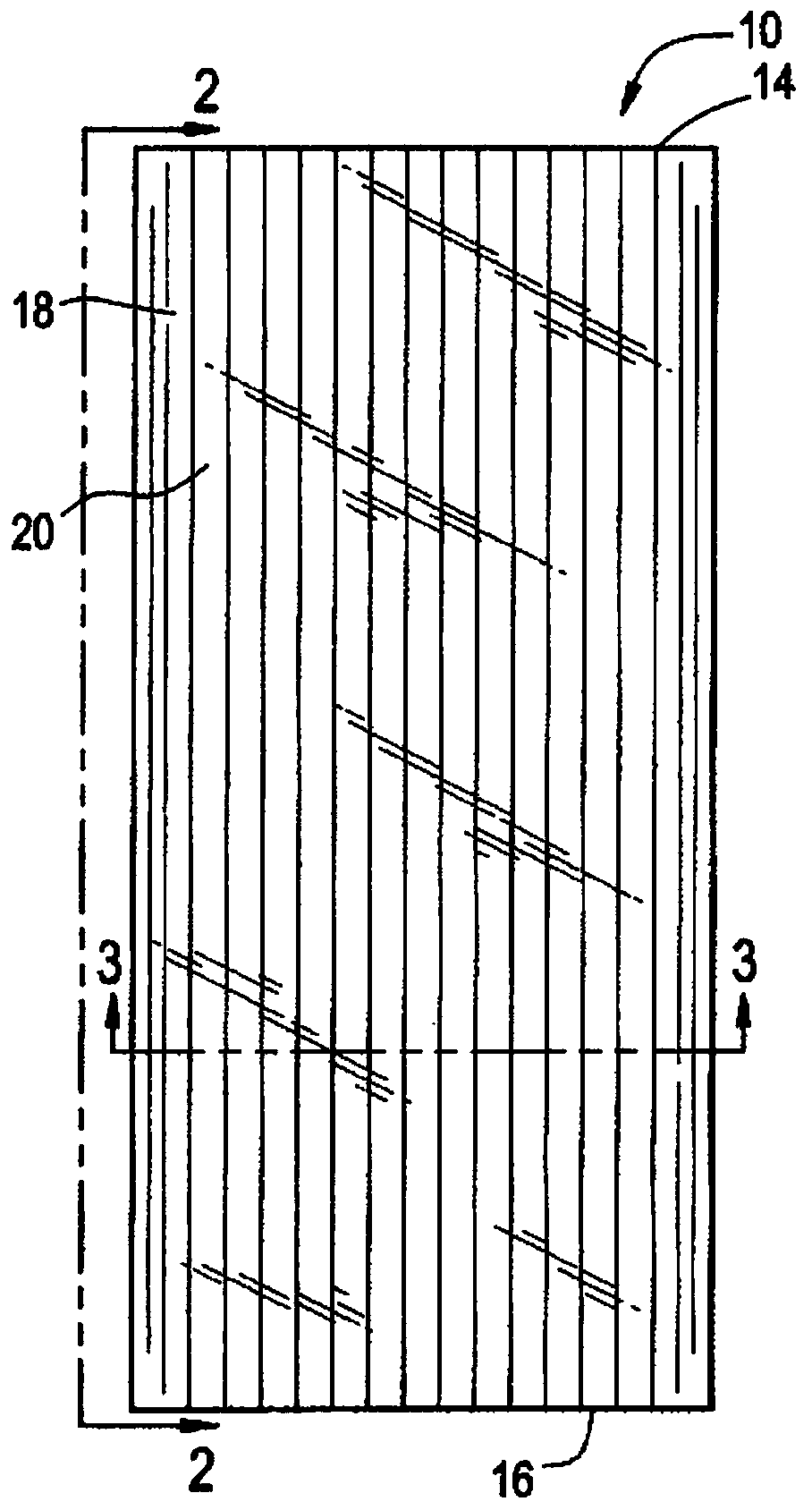

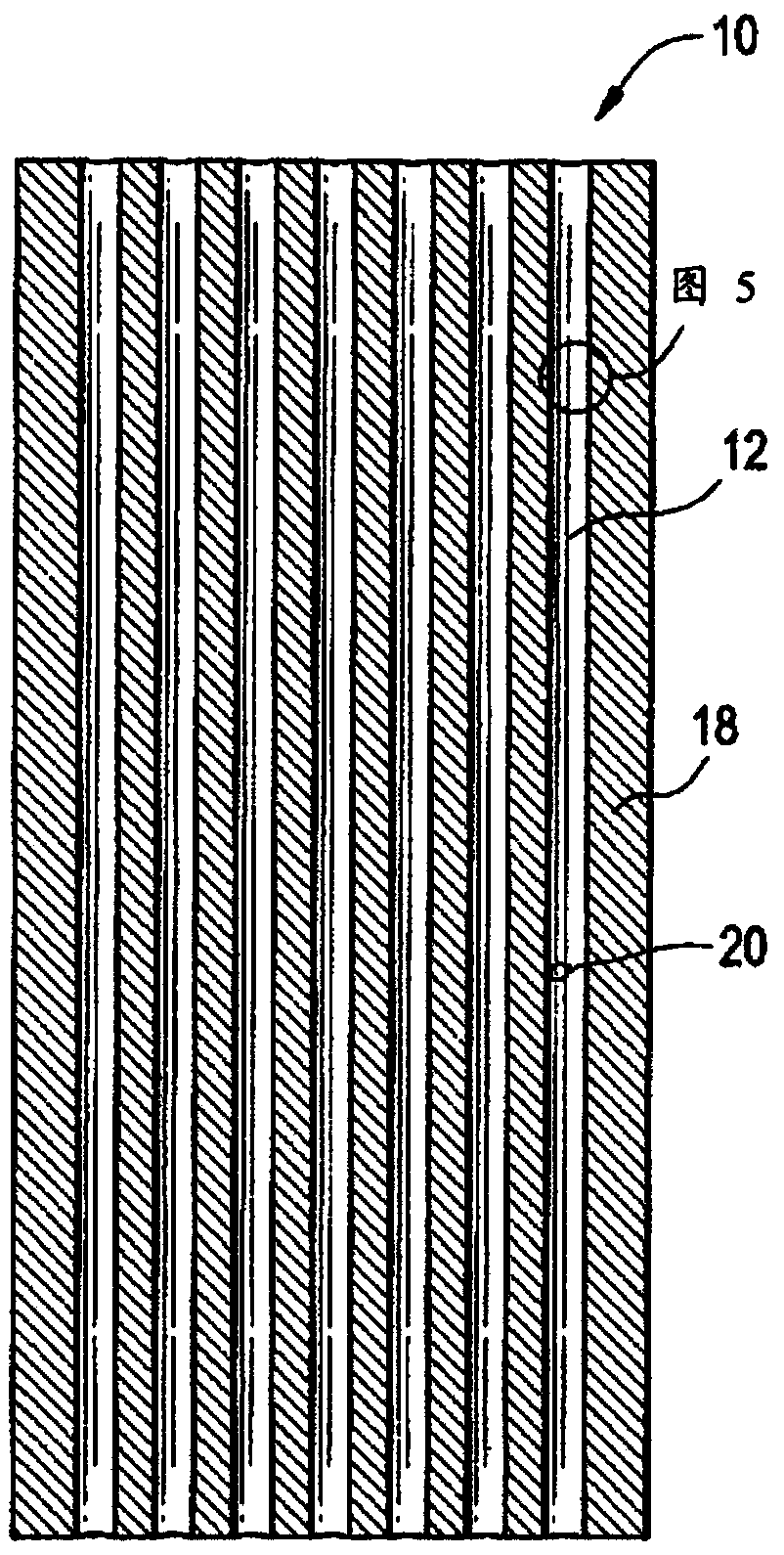

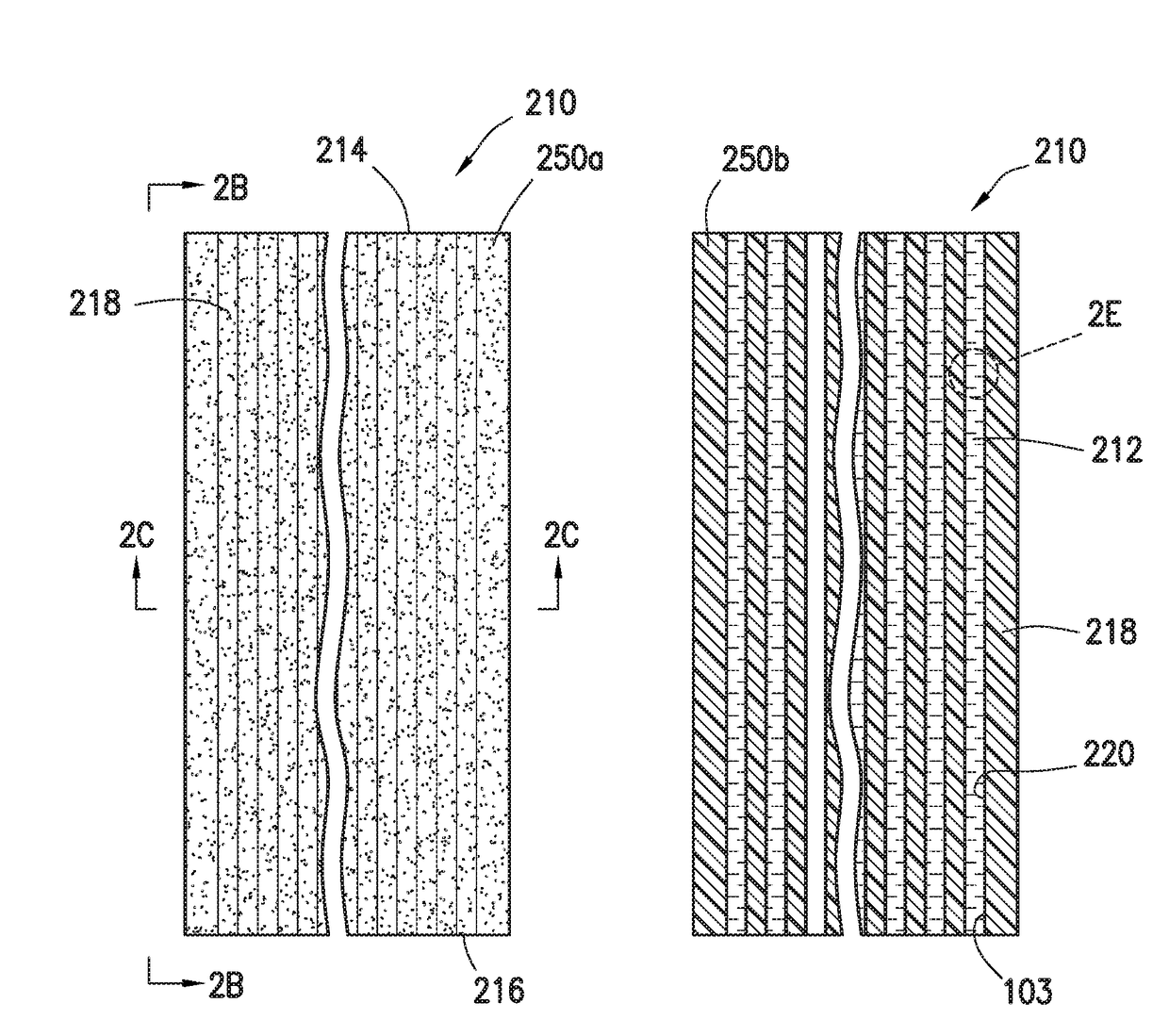

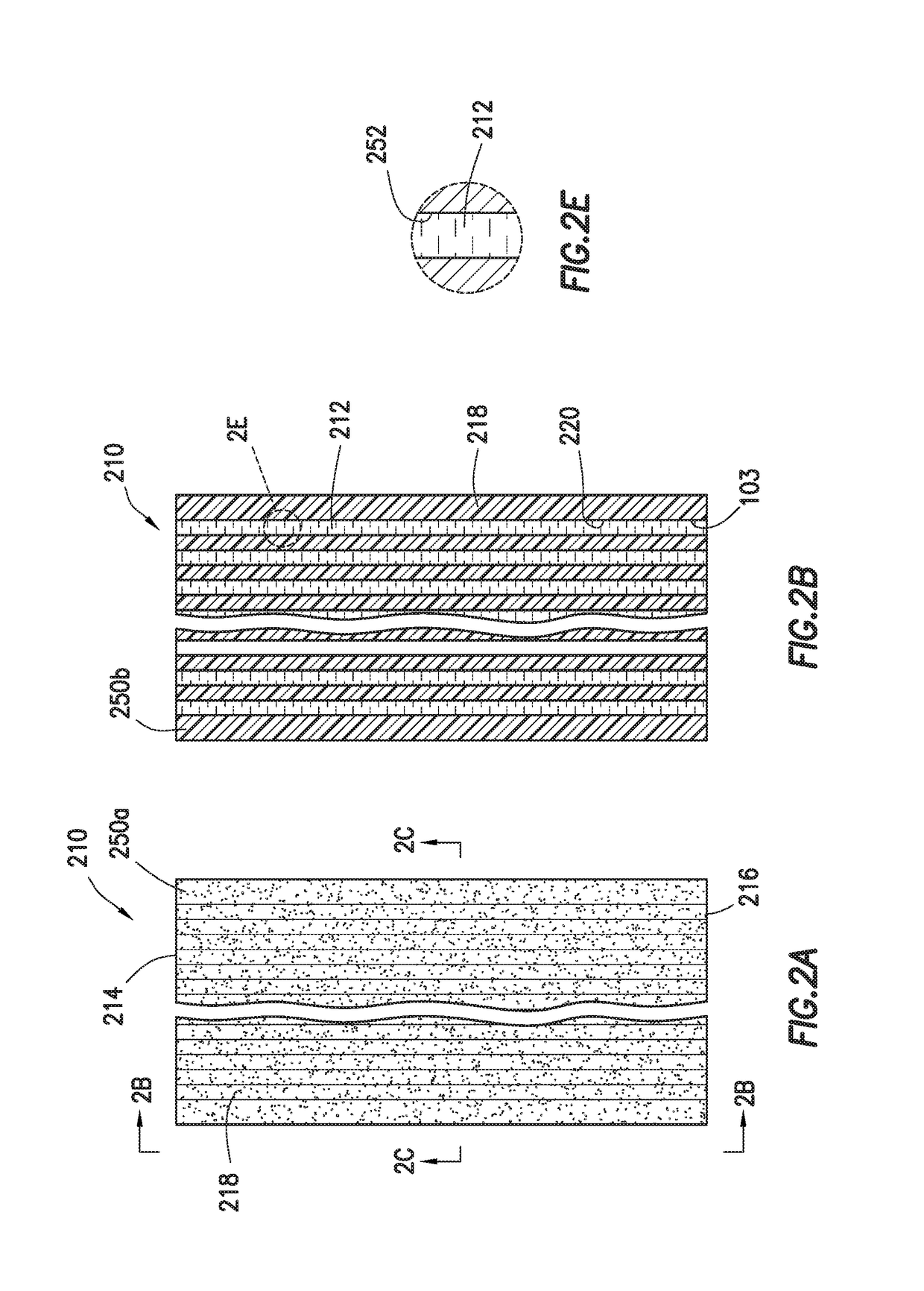

Microcapillary films containing phase change materials

The instant invention provides microcapillary films containing phase change materials. The inventive microcapillary film containing phase change materials according to the present invention has a first end and a second end, and comprises:(a) a matrix comprising a thermoplastic material, (b) at least one or more channels disposed in parallel in said matrix from the first end to the second end of said microcapillary film, wherein said one or more channels are at least 5 [mu]m apart from each other, wherein each said one or more channels have a diameter in the range of at least 5 [mu]m; and (c) at least one or more phase change materials disposed in said one or more channels; wherein said microcapillary film has a thickness in the range of from 10 [mu]m to 2000 [mu]m.

Owner:DOW GLOBAL TECH LLC

Eye cream containing plant extract

InactiveCN104069015APromotes moderate crosslinkingGood for healthCosmetic preparationsToilet preparationsGlycerolSkin hyperpigmentation

The invention discloses eye cream containing plant extract. The eye cream comprises the following components in percentage by mass: 35-75 percent of blueberry anthocyanin, 1-15 percent of active plant peptides, 5-20 percent of glycerinum, 1-10 percent of vitamin E, 1-5 percent of amino acid humectant and 5-25 percent of purified water. According to the eye cream, blueberry anthocyanin can be used for effectively stopping generation of hard protease and inhibiting the activity of the hard protease to stop free radical or elastase from degrading hard protein, so that the skin health condition can be improved from the inside, the micro-capillary circulation of skin around eyes can be improved, and dark circle and other eye skin problems can be solved; vitamin E can be used for relieving skin hyperpigmentation; the amino acid humectant can be used for effectively regulating the skin moisture content; the active peptide which is traditionally used in healthy foods is used in the eye cream, and the cream is introduced to skin base in an 'absorption' manner, the nutrition supply of skin is increased, and the skin immunity is improved.

Owner:GUANGZHOU DAAO COSMETICS

Novel anti-seepage PCCP (Prestressed Concrete Cylinder Pipe) and production method

InactiveCN104180085AImprove compactnessNot corrodedPretreated surfacesCorrosion preventionSurface layerPre stress

The invention discloses a novel anti-seepage PCCP (Prestressed Concrete Cylinder Pipe) and a production method. The novel anti-seepage PCCP is characterized in that the surface of the novel anti-seepage PCCP is formed by coating a flat, dense and smooth cement slurry anti-seepage protection layer on the surface of the outer layer of a traditional PCCP again. The novel anti-seepage PCCP and the production method, disclosed by the invention have the beneficial effects that the production and processing method is simple and convenient, the surface of the produced novel anti-seepage PCCP is smooth, the density of the protection layer of the surface layer is high, micro capillary channels which are mutually communicated are not formed in an outer mortar protection layer, the waterproof performance is very high, a pipe core of a steel cylinder and a prestressed steel wire can be effectively prevented from being corroded by an external corrosion environment, the service life of a pipeline is prolonged, and an accident caused as the pipeline is corroded can be prevented from happening.

Owner:山东沃特管业有限责任公司

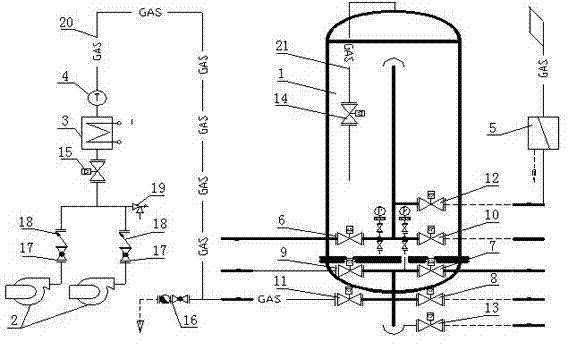

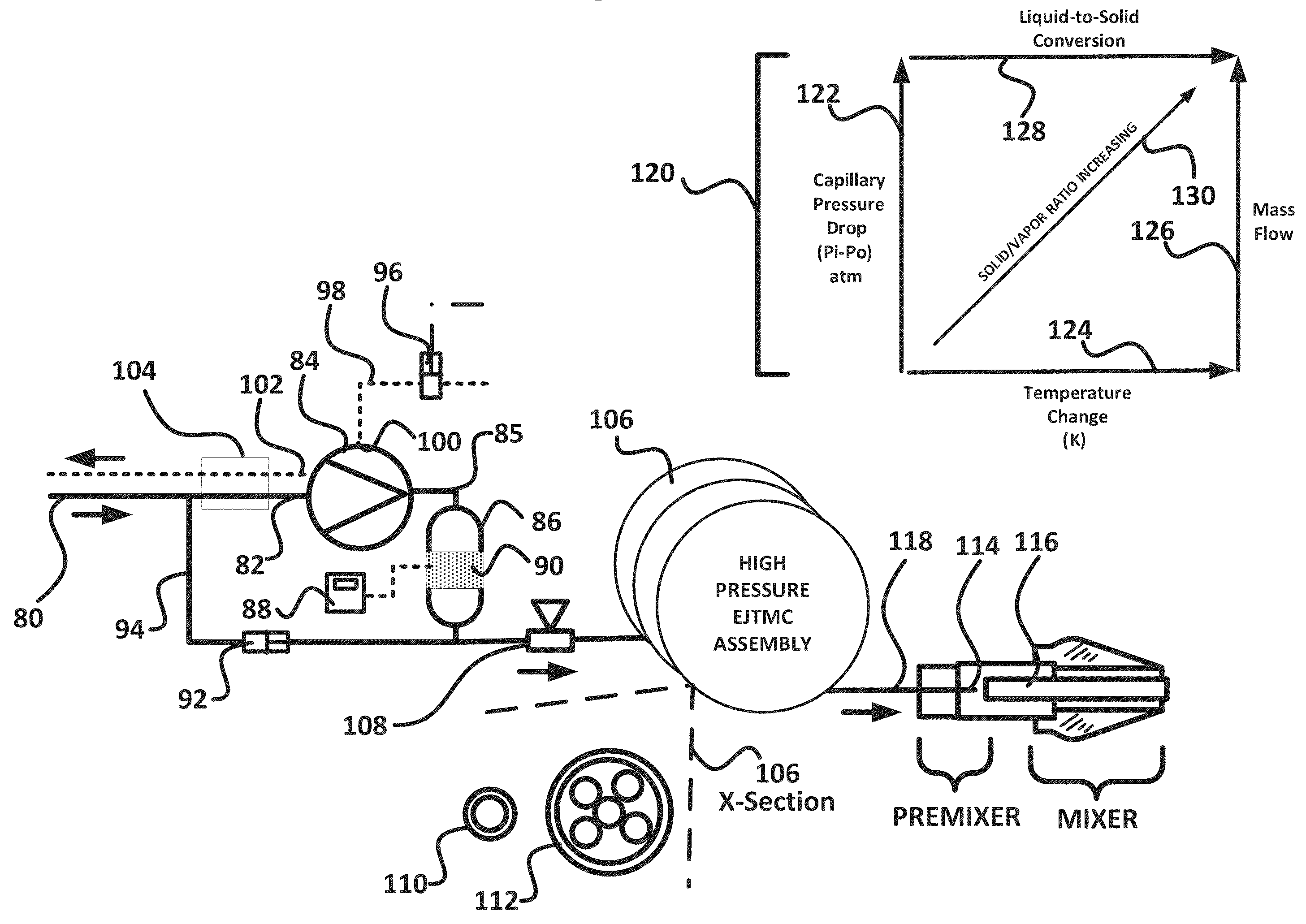

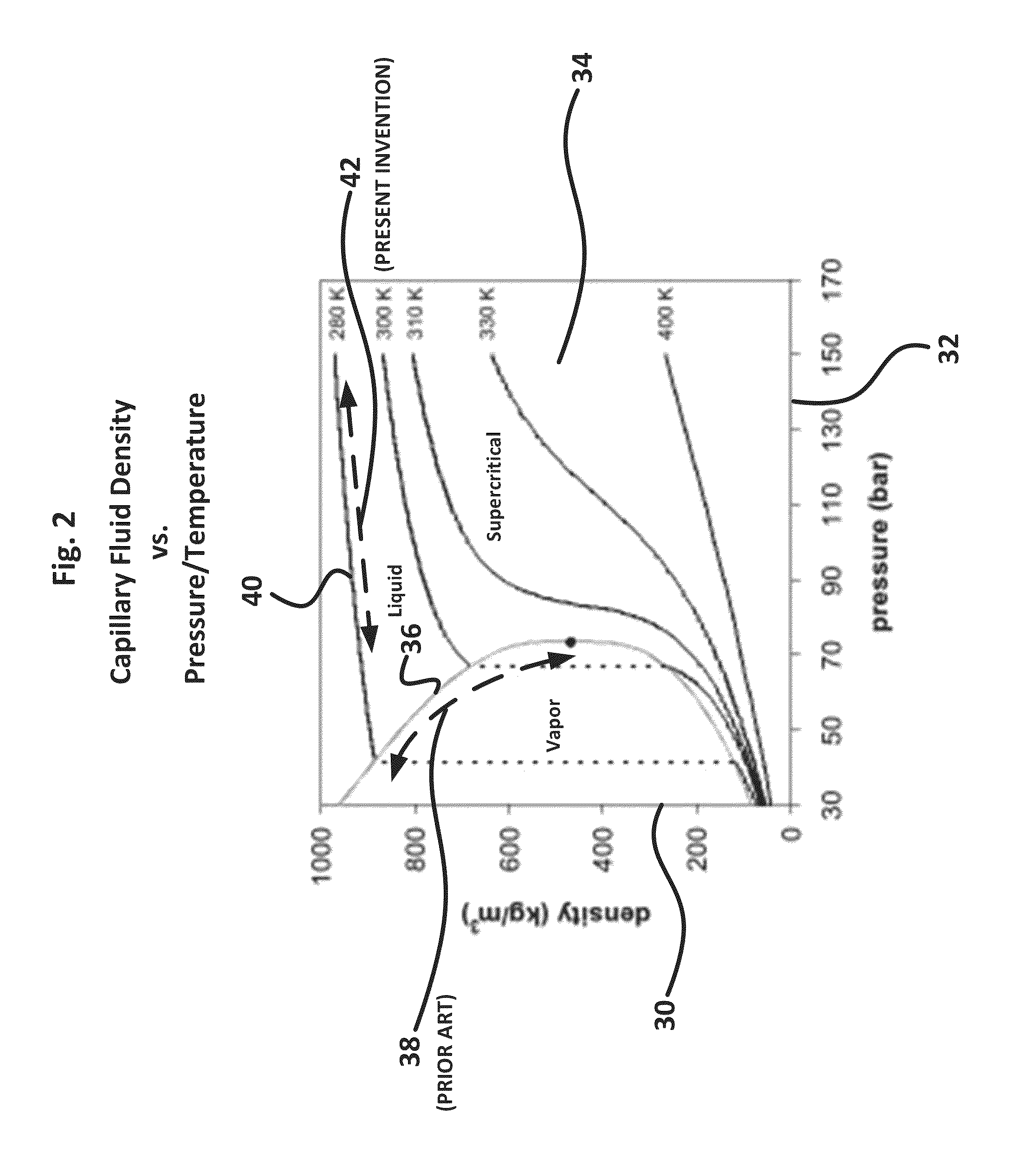

CO2 composite spray method and apparatus

A method and apparatus is disclosed for the production, delivery and control of microscopic quantities of minute solid carbon dioxide (CO2) particles having uniform density and distribution for use in a CO2 Composite Spray process, which employs compression of liquid carbon dioxide to form a supersaturated liquid, which is then condensed via micro-capillaries into minute and highly energetic solid carbon dioxide particles, which are injected into a propellant gas stream.

Owner:HITACHI HIGH-TECH CORP

Novel uniformly flowing liquid lithium limiter structure applied to fusion device

ActiveCN107910075ARealize the supplyEvenly distributedNuclear energy generationThermonuclear fusion reactorEngineeringLiquid lithium

The invention discloses a novel uniformly flowing liquid lithium limiter structure applied to a fusion device, which comprises a collection box, wherein the bottom end of the collection box is provided with double built-in electromagnetic pump, a limiter base is arranged above the collection box, the base of the limiter base is provided with a heating wire and a thermocouple, the outer surface ofthe inner side of the limiter base is clamped with supply pipes connected with liquid lithium, a pump channel is welded between two electrodes in the double built-in electromagnetic pump, the pump channel is communicated with the supply pipes above, the top of the limiter base is provided with a distribution box, and the distribution box is integrally molded and has a structure with uniformly distributed distribution holes. The novel uniformly flowing liquid lithium limiter structure can better achieve supply of the liquid lithium by using a device toroidal field and the additional direct current driving double built-in electromagnetic pump structure, can realize uniform distribution of the liquid lithium through the integrally molded distribution box, and can effectively improve the spreading uniformity of the liquid lithium by using the limiter base with good lamination and a micro-capillary structure perpendicular to the flowing direction of the liquid lithium.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

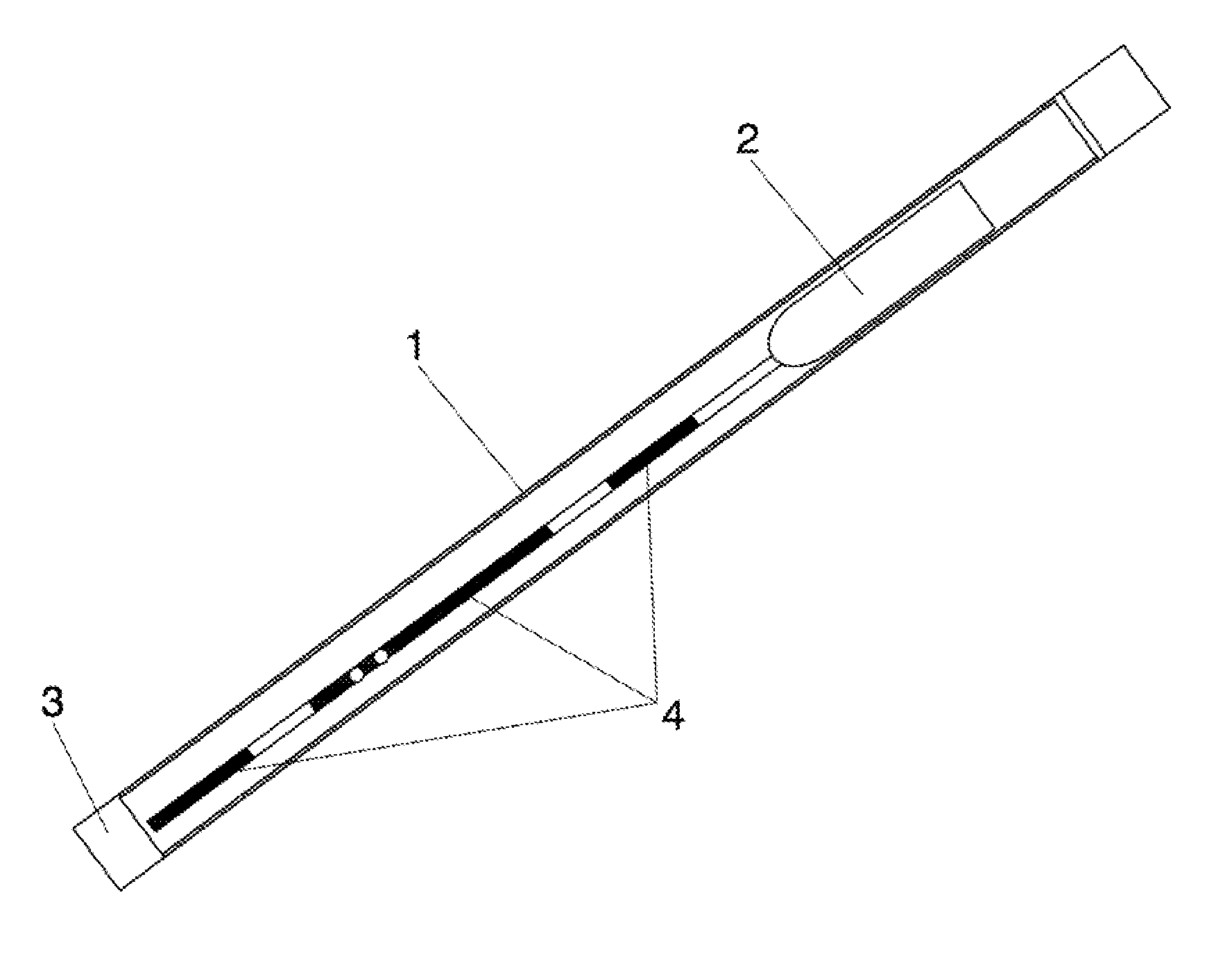

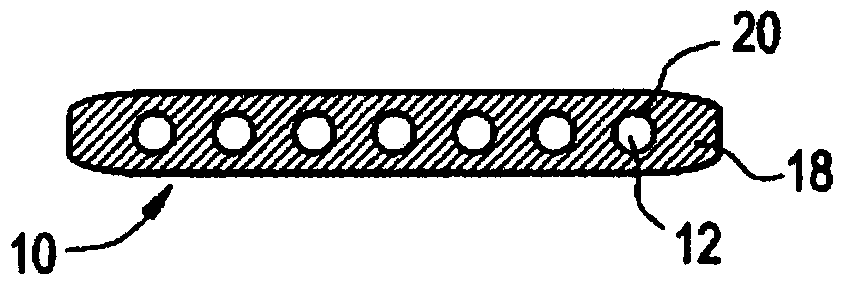

Peelable cable jacket having designed microstructures and methods for making peelable cable jackets having designed microstructures

Coated conductors comprising a conductor and a peelable polymeric coating at least partially surrounding the conductor, where the peelable polymeric coating comprises from 1 to 8 microcapillaries that define individual, discrete void spaces. Also disclosed are methods for making such coated conductors.

Owner:DOW GLOBAL TECH LLC

LED explosion-proof lamp

ActiveCN105546495ALow reliabilityAvoid high ambient temperatureLighting heating/cooling arrangementsLighting safety devicesEngineeringPhase change

The invention provides an LED explosion-proof lamp. The LED explosion-proof lamp comprises a power source cavity and a light source cavity located on two sides of a micro capillary groove composite phase change cooling heat radiator. In the light source cavity, an LED light source installation extension plate is installed between the surface of the micro capillary groove composite phase change cooling heat radiator and a light source. The lateral surface of the heat radiator is formed by a plurality of vertically arranged heat radiation fins in a surrounding mode, and gaps exist between the heat radiation fins. On the premise of not affecting explosion-proof safety, an explosion-proof structure and the micro capillary groove composite phase change technology heat radiator are combined, the low-efficiency heat radiation method that a traditional explosion-proof lamp only depends on an explosion-proof outer shell for heat radiation is changed, the LED lamp is more widely used in the explosion-proof field, and the lighting effect of the lamp and the reliability of the light source are higher. A power source and the light source are separated by the heat radiator, the heat radiation effect is reinforced, the temperature of the application environment of the power source is lowered, and the reliability and the service life of the power source are better guaranteed.

Owner:湖南玖泓节能科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com