Regenerating method of active carbon filter

A technology of activated carbon filter and activated carbon filter layer, which is applied in the regeneration field of activated carbon filter, which can solve the problems of low cost, high cleaning and regeneration cost, inability to effectively restore the adsorption function, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

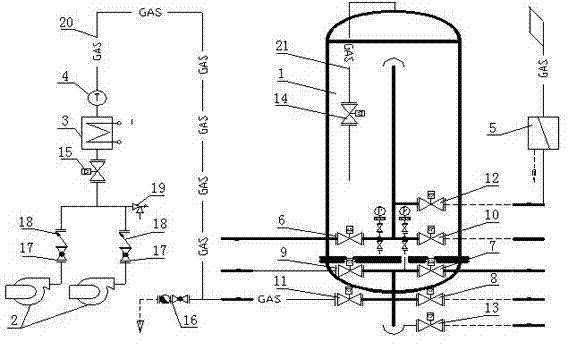

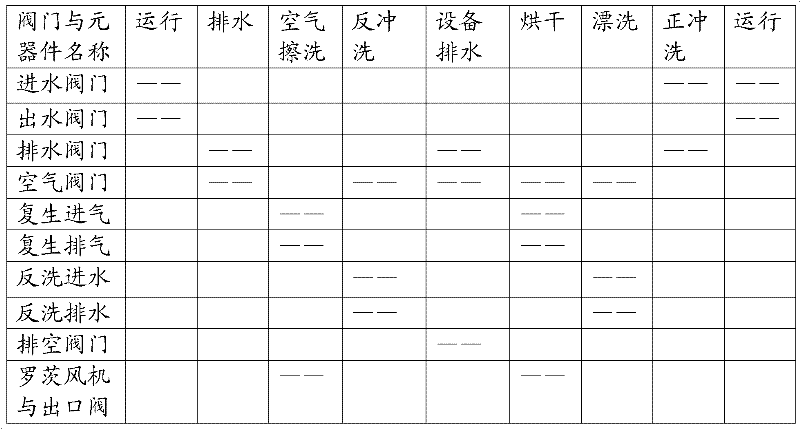

[0028] 1. Activated carbon filter regeneration device

[0029] The regeneration device and components used in the activated carbon filter regeneration method of the present invention include: an activated carbon filter 1; a Roots blower 2; an air electric heater 3; a temperature controller 4; a dust collector 5 and a system valve. The system valves include: water inlet valve 6; water outlet valve 7; drain valve 8; backwash water inlet valve 9; backwash drain valve 10; rebirth intake valve 11; rebirth exhaust valve 12; Valve 14; Roots blower outlet valve 15. The Roots blower 2 is provided with a primary valve 17 , a check valve 18 , and an outlet safety valve 19 . The electric air heater 3 is connected to the Roots fan outlet valve 15, the temperature controller 4 is connected to the electric air heater 3, and the temperature controller 4 is connected to the regenerative intake valve 11 through the first air delivery pipe 20 , the regenerative exhaust valve 12 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com