Backlight module

A backlight module and light source technology, applied in the field of heat dissipation structure, can solve the problems of light guide plate deflection, uneven heat dissipation, high thermal resistance, etc., to avoid the generation of local hot spots and solve the effect of uneven heating and deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and embodiments. After any person skilled in the art understands the preferred embodiments of the present invention, they can be changed and modified by the technology taught by the present invention without departing from it. Spirit and protection scope of the present invention.

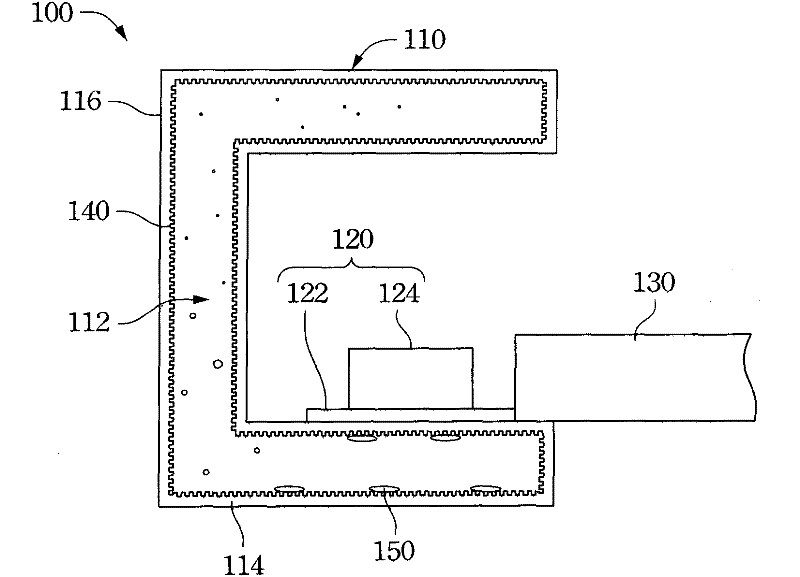

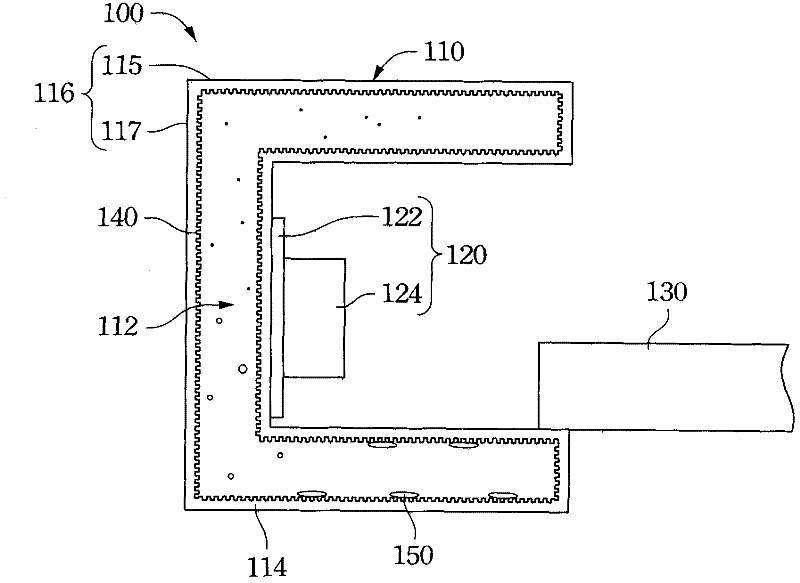

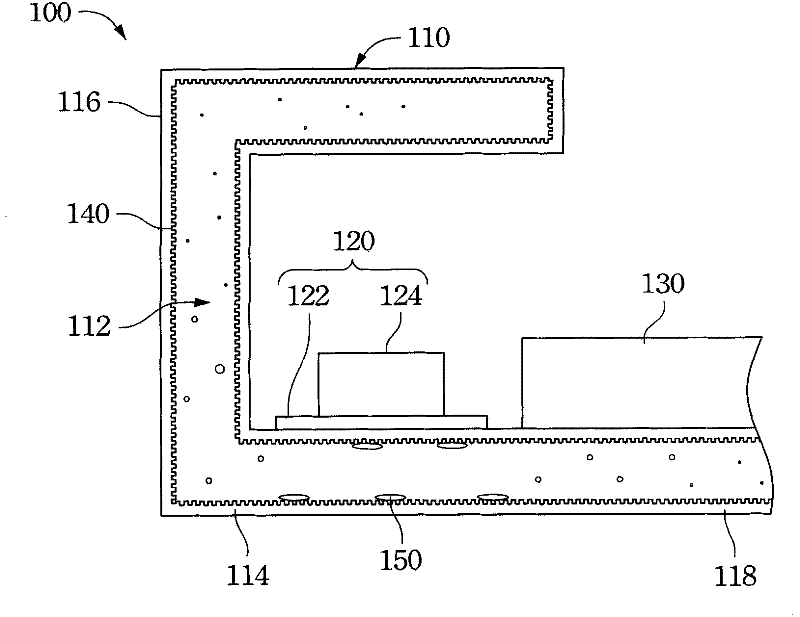

[0019] refer to figure 1 , is a partial cross-sectional view illustrating the first embodiment of the backlight module of the present invention. The backlight module 100 includes a bracket 110 , a light source 120 disposed on the bracket 110 , and a light guide plate 130 located on one side of the light source 120 . The bracket 110 has a cavity 112 , and the cavity 112 is the interior of the whole bracket 110 . The backlight module 100 further includes a microcapillary structure 140 formed on the inner surface of the cavity 112 , and a fluid 150 located in the cavity 112 .

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com