Preparation method of sapphire micro-capillary and die used in preparation method

A microcapillary and sapphire technology, applied in the field of sapphire microcapillary preparation, can solve the problems of poor concentricity between the inner hole and the sapphire tube, unsuitable sapphire tube, etc., and achieve good transparency, high product yield, and good crystal integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a sapphire microcapillary, using the edge-limited film feeding and pulling growth technology, comprising the following preparation method:

[0024] 1), the selection of raw materials, select high-purity aluminum oxide as raw materials;

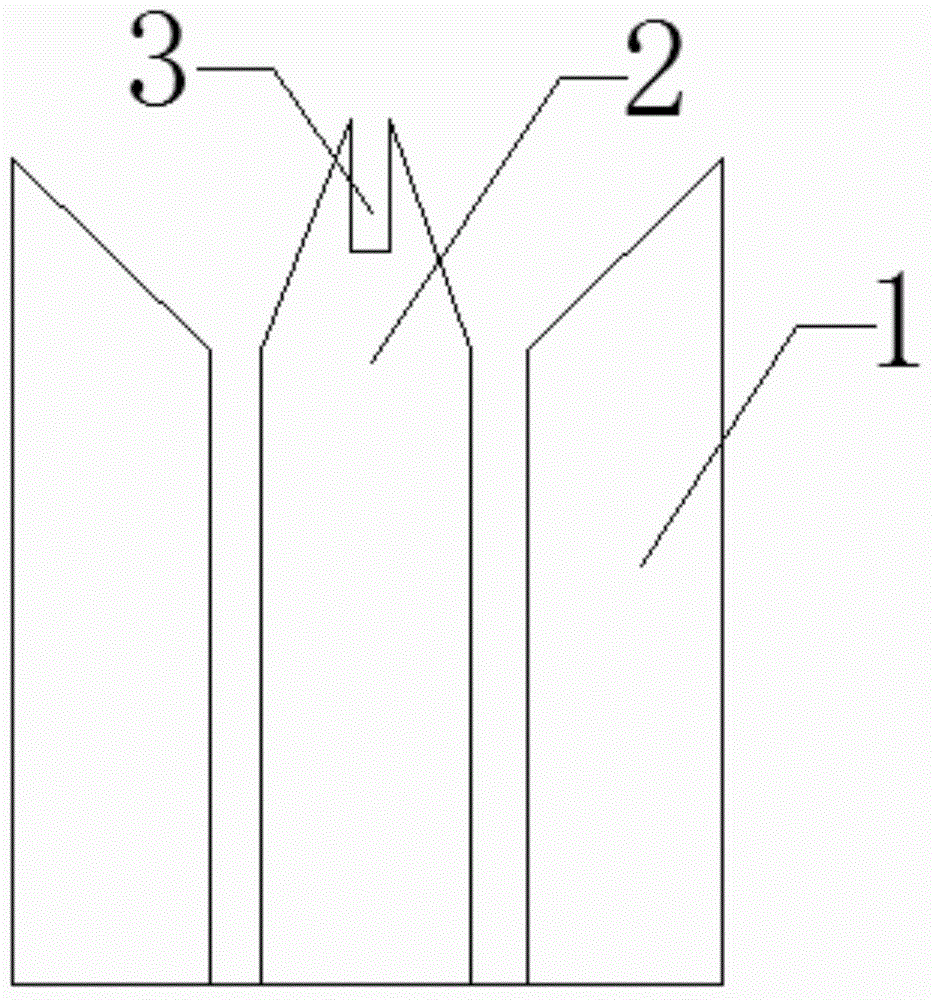

[0025] 2) The processing of the mold, the mold is divided into two parts, the inner mold and the outer mold. Both the inner mold and the outer mold are processed to a mirror level, and then a small hole is ground in the middle of the top of the inner mold, and then the small hole Process the top of the inner mold into a tapered shape as a benchmark, and then chamfer the outer mold. The concentricity between the small hole on the top of the inner mold and the edge of the inner mold is less than 0.01mm, and the clamping surface between the slope of the outer mold and the outer wall of the inner mold The angle is 100°; the diameter of the small hole of the inner mold is 0.1mm, and the depth is 2mm; the distance betwe...

Embodiment 2

[0029] A method for preparing a sapphire microcapillary, using the edge-limited film feeding and pulling growth technology, comprising the following preparation method:

[0030] 1), the selection of raw materials, select high-purity aluminum oxide as raw materials;

[0031] 2) The processing of the mold, the mold is divided into two parts, the inner mold and the outer mold. Both the inner mold and the outer mold are processed to a mirror level, and then a small hole is ground in the middle of the top of the inner mold, and then the small hole Process the top of the inner mold into a tapered shape as a benchmark, and then chamfer the outer mold. The concentricity between the small hole on the top of the inner mold and the edge of the inner mold is less than 0.01mm, and the clamping surface between the slope of the outer mold and the outer wall of the inner mold The angle is 120°; the diameter of the small hole of the inner mold is 0.2mm, and the depth is 3mm; the distance betwe...

Embodiment 3

[0035] A method for preparing a sapphire microcapillary, using the edge-limited film feeding and pulling growth technology, comprising the following preparation method:

[0036] 1), the selection of raw materials, select high-purity aluminum oxide as raw materials;

[0037] 2) The processing of the mold, the mold is divided into two parts, the inner mold and the outer mold. Both the inner mold and the outer mold are processed to a mirror level, and then a small hole is ground in the middle of the top of the inner mold, and then the small hole Process the top of the inner mold into a tapered shape as a benchmark, and then chamfer the outer mold. The concentricity between the small hole on the top of the inner mold and the edge of the inner mold is less than 0.01mm, and the clamping surface between the slope of the outer mold and the outer wall of the inner mold The angle is 110°; the diameter of the small hole of the inner mold is 0.4mm, and the depth is 2mm; the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com