Producing device and its producing method for capillary tissue micro groove of heat pipe inner wall

A technology for manufacturing equipment and micro-grooves, applied in the field of the manufacture of capillary micro-grooves and capillary micro-grooves, can solve the problem of inconvenient operation, poor contact between the metal woven mesh and the inner wall of the heat pipe, damage to the chip, etc. problem, to achieve the effect of excellent heat transfer performance, reliable capillary structure, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

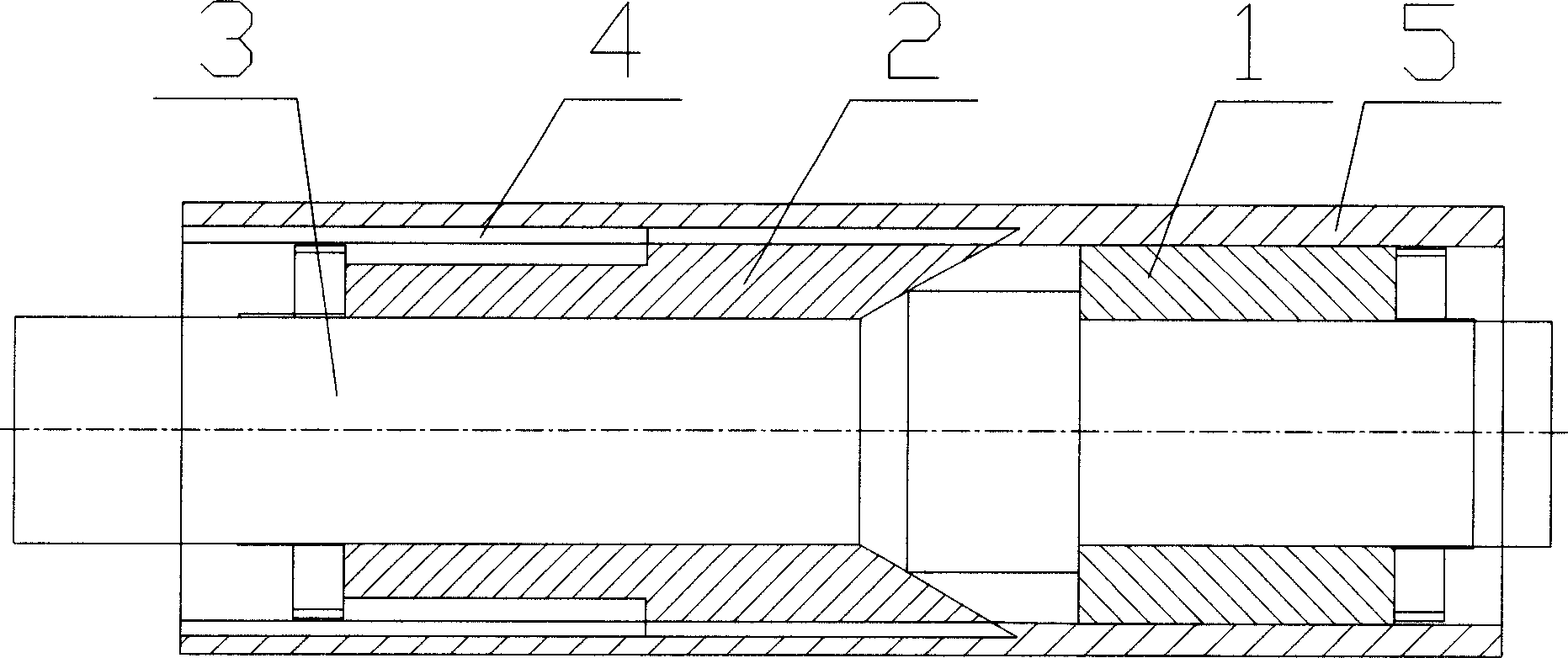

[0025] like figure 1 As shown, the manufacturing equipment of the heat pipe with capillary micro-grooves on the inner wall of the present invention is mainly composed of a positioning rod 1, a cutter 2 and a pull rod 3; .

[0026] When working, fix the base tube 5 of the heat pipe of the workpiece on the frame, make the pull rod pass through the base tube, be clamped by the traction device and drive the pull rod 3 to move, and when the pull rod 3 moves from one end of the base tube to the other end under the action of tension, The positioning rod 1 plays the role of positioning and guiding, and drives the cutter 2 to advance in the axial direction, and the cutting edge on the cutter plows the capillary micro-groove structure 4 on the inner wall of the base tube 5 .

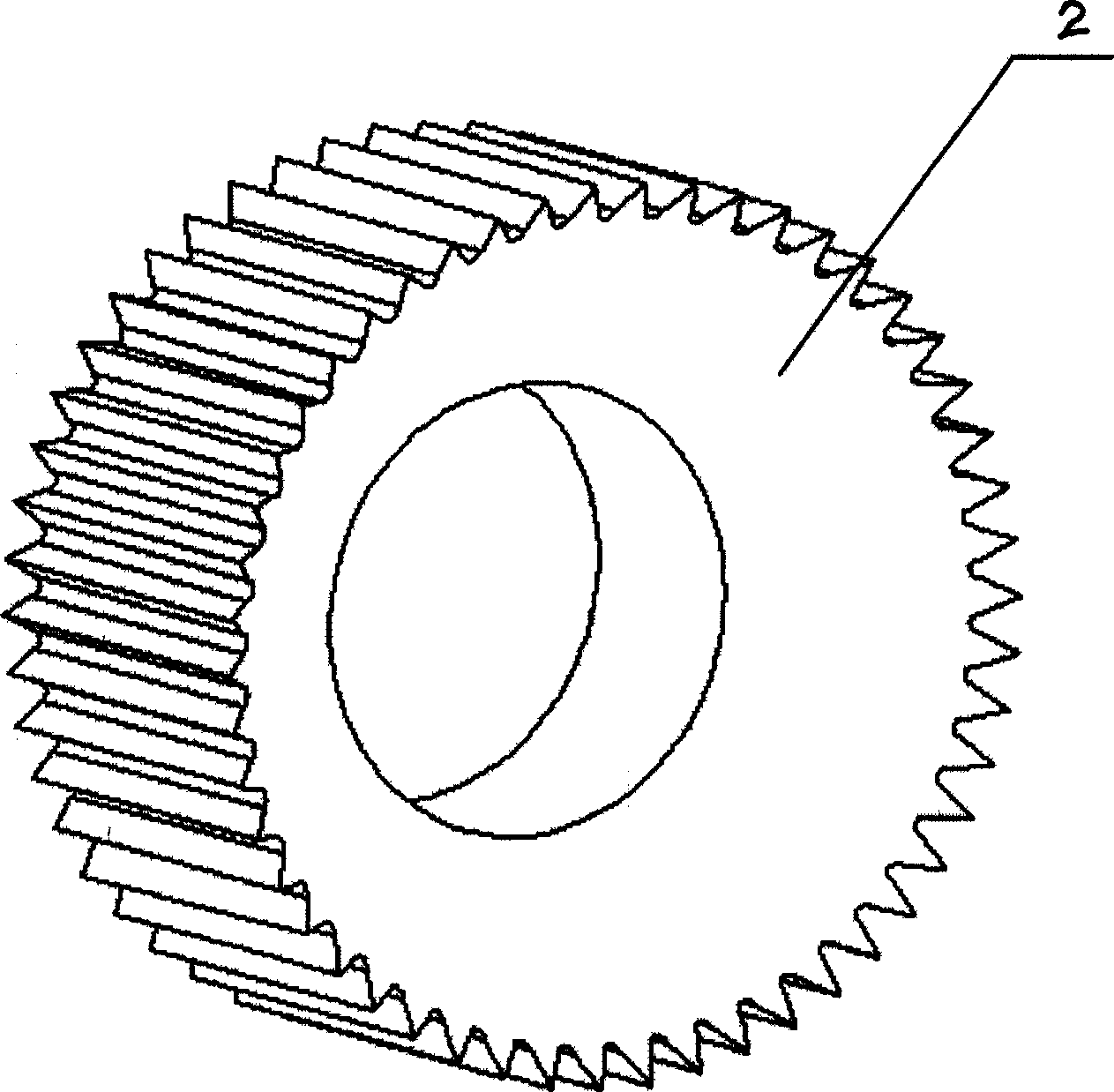

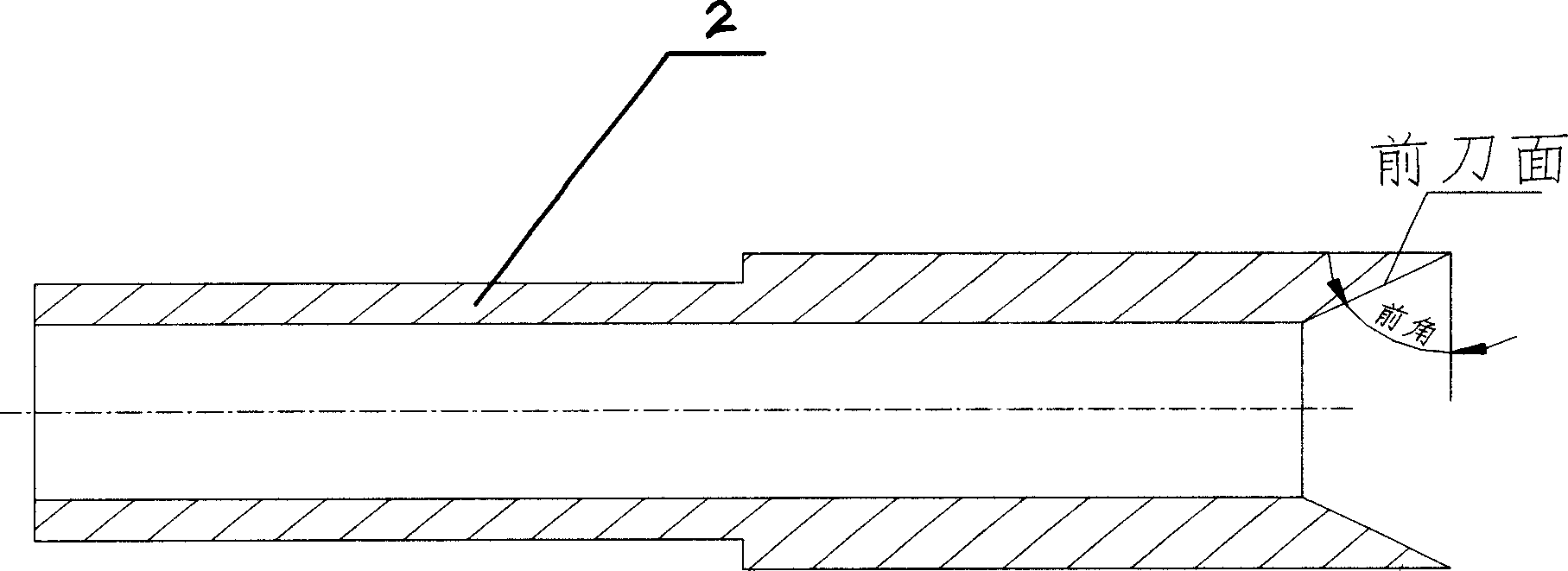

[0027] like figure 2 , 3 As shown, the tool is cylindrical, and several alternate cutting edges and grooves are evenly distributed along the circumference of the outer surface, and the rake face is processed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com