Hollow-core polarization-maintaining anti-resonance optical fiber and preparation method thereof

An anti-resonant, hollow-core technology, applied to multi-layer core/clad optical fibers, clad optical fibers, glass manufacturing equipment, etc., can solve the problems of difficult design and preparation of hollow-core polarization-maintaining optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a hollow-core polarization-maintaining anti-resonant optical fiber proposed in this embodiment comprises the following steps:

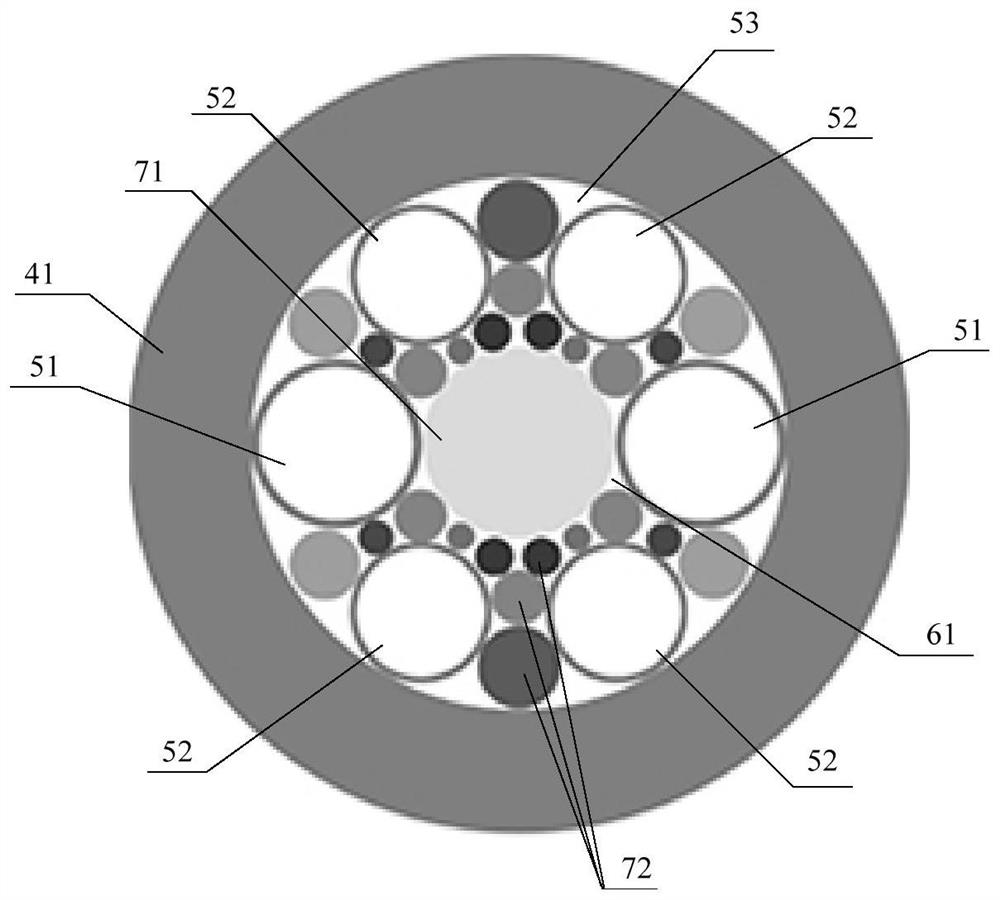

[0037] Step 1: If Figure 1a As shown, a solid casing 41 is selected; then in the tube hole of the solid casing 41, a total of 6 microcapillaries are arranged in a ring evenly spaced around the tube wall, so that the outer walls of all the microcapillaries are in contact with the solid casing 41. The inner walls of the two microcapillaries are close to each other, and the outer diameters of the two microcapillaries are greater than the outer diameters of the remaining four microcapillaries, and the two large diameter microcapillaries are defined as the first microcapillary 51, while the remaining four small diameter microcapillaries are defined as the first microcapillary 51. The capillary is defined as the second microcapillary 52, and the standard for the position arrangement of all the first microcapillary 51 and the se...

Embodiment 2

[0046] A method for preparing a hollow-core polarization-maintaining anti-resonant optical fiber proposed in this embodiment comprises the following steps:

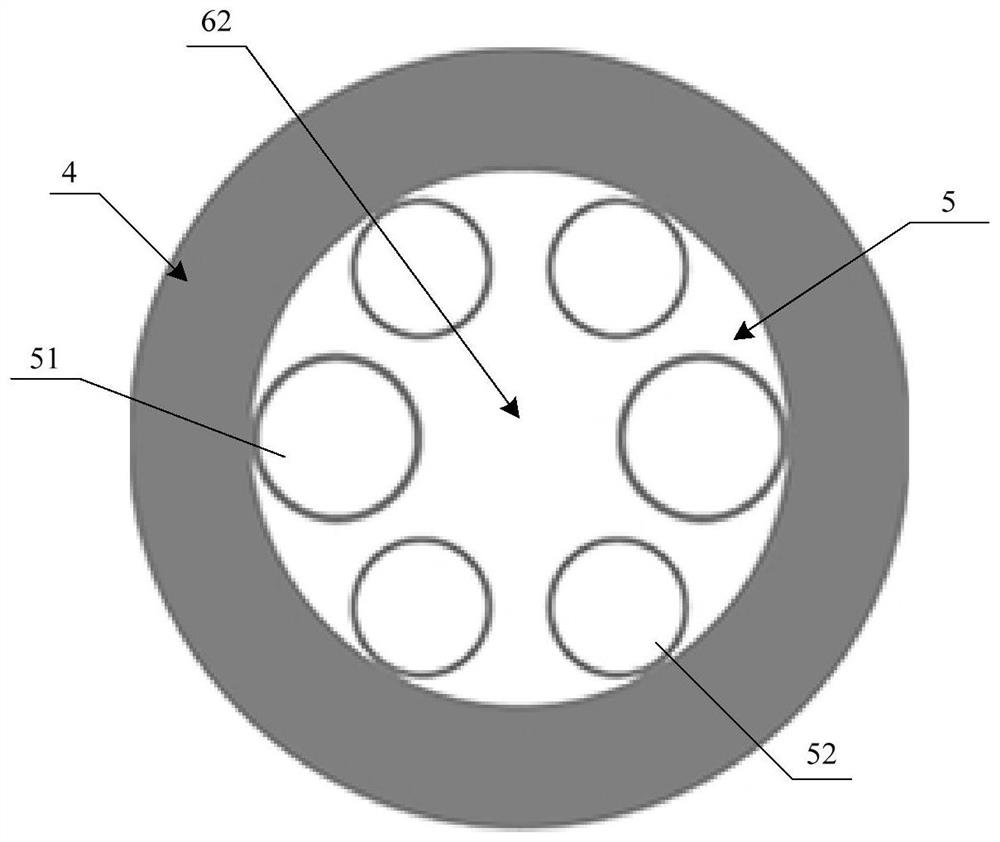

[0047] Step 1: If Figure 2a As shown, select a solid sleeve 41; then in the tube hole of the solid sleeve 41, close to the wall of the solid sleeve 41 and arrange a circle of 6 microcapillaries evenly in a circle, that is, the outer walls of all the microcapillaries Closely attached to the inner wall of the solid casing 41, wherein the outer diameters of two microcapillaries are smaller than the outer diameters of the remaining four microcapillaries, and these two small-diameter microcapillaries are defined as the first microcapillary 51, and the remaining four microcapillaries are defined as the first microcapillary 51. The microcapillary with a large diameter is defined as the second microcapillary 52, and the standard for the position arrangement of all the first microcapillary 51 and the second microcapillary 52 alon...

Embodiment 3

[0057] A method for preparing a hollow-core polarization-maintaining anti-resonant optical fiber proposed in this embodiment comprises the following steps:

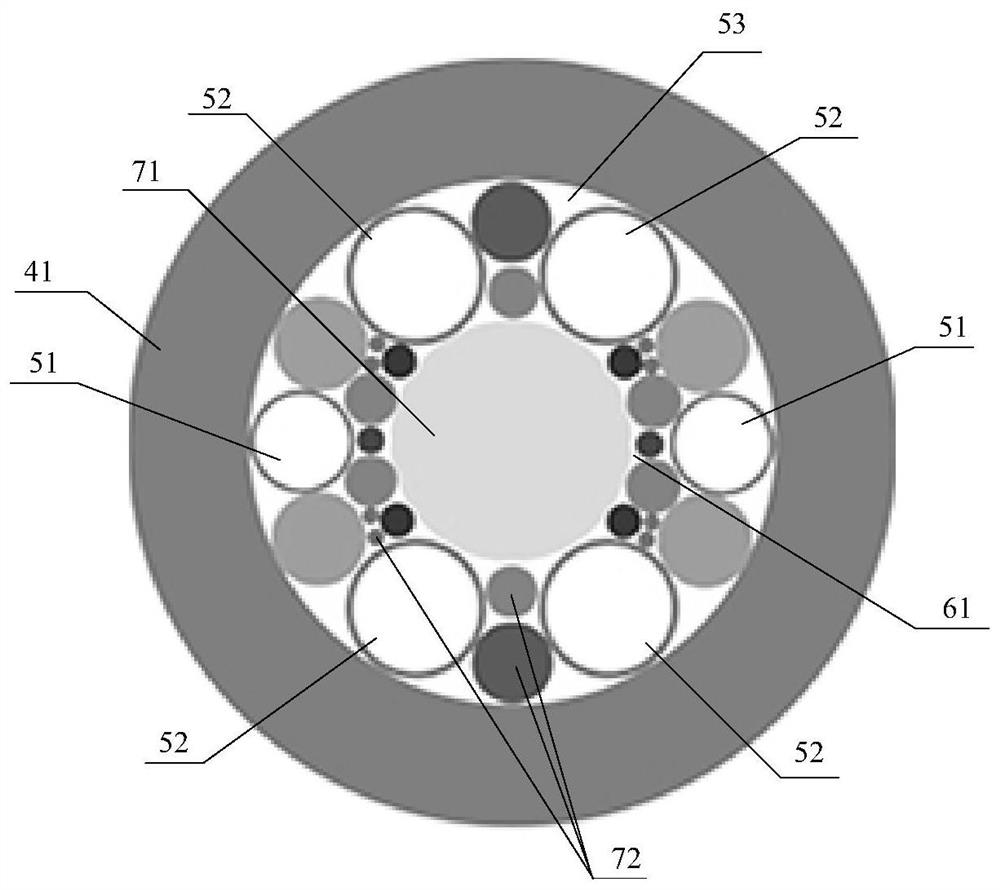

[0058] Step 1: If Figure 3a As shown, select a solid sleeve 41; then in the tube hole of the solid sleeve 41, close to the wall of the solid sleeve 41 and arrange a circle of 6 microcapillaries evenly in a circle, that is, the outer walls of all the microcapillaries Closely attached to the inner wall of the solid casing 41, wherein the outer diameter of one microcapillary is smaller than the outer diameters of the remaining five microcapillaries, and this one small-diameter microcapillary is defined as the first microcapillary 51, and the remaining five microcapillaries are defined as the first microcapillary 51. The microcapillary with a large diameter is defined as the second microcapillary 52, and the standard for the position arrangement of all the first microcapillary 51 and the second microcapillary 52 along the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com