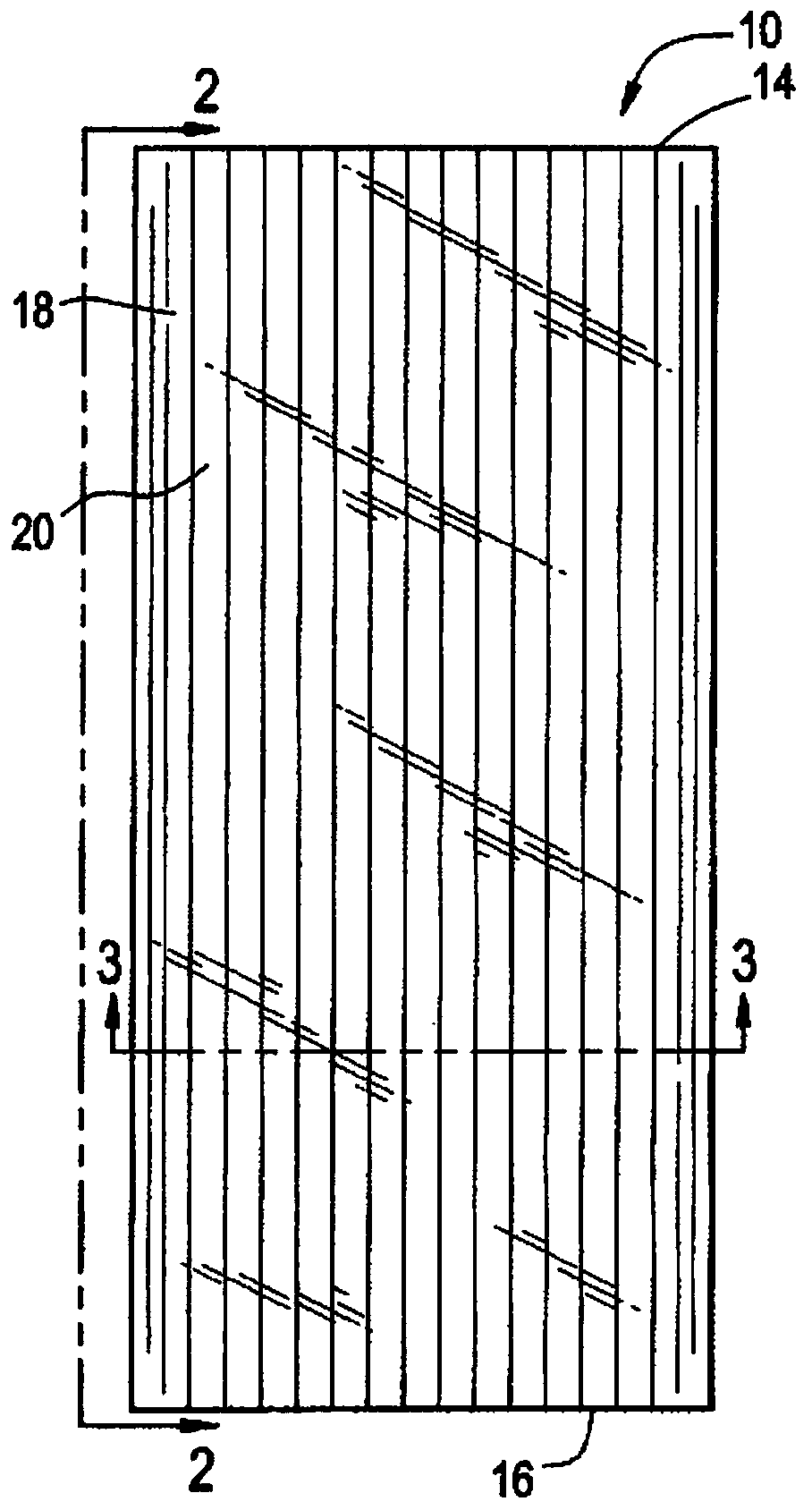

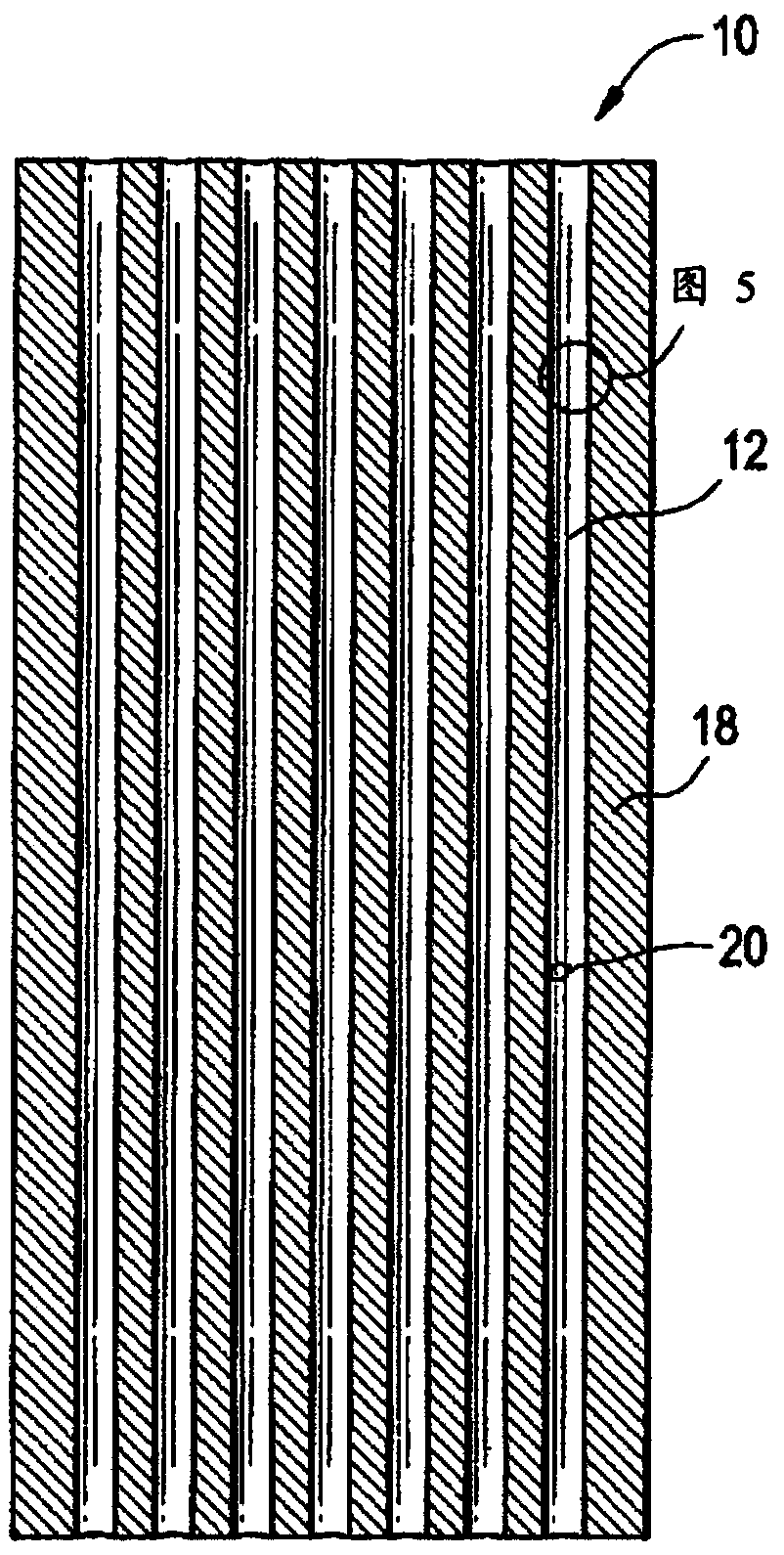

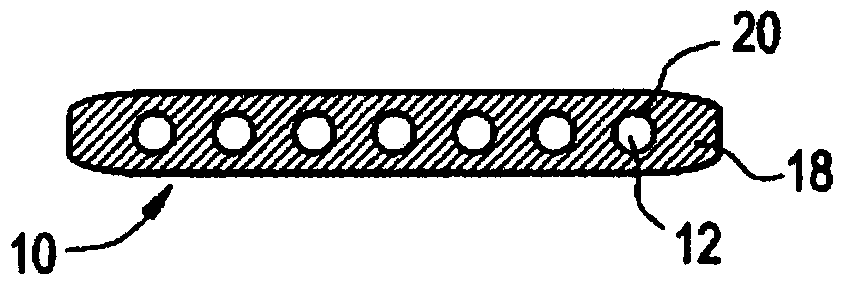

Microcapillary films containing phase change materials

A technology of phase change material and thermoplastic material, applied in the field of microcapillary membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] The inventive microcapillary membrane 1 comprising a phase change material was prepared according to the following procedure.

[0079] Matrix materials include linear low density polyethylene (LLDPE), which is known by the trade name DOWLEX TM NG5056G is available from The Dow Chemical Company and has a density of about 0.919 g / cm according to ASTM-D792 3 , according to the melt index measured according to ISO1133 (I 2 ) is about 1.1 g / 10 minutes. Phase change materials include methoxypolyethylene glycol, which goes by the trade name CARBOWAX TM MPEG750 is available from The Dow Chemical Company.

[0080] Both the primary and secondary extruders are single screw extruders. The main extruder was a Betol 1820J with a screw diameter of about 20 mm connected to a gear pump providing a non-pulstile polymer flow. Downstream of the microcapillary film die is a set of nip rolls equipped with an adjustable nip (Dr. Collin GmbH "Techline" CR72T). The secondary extruder was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com