A micropump based on capillary action and its application method

A capillary action and capillary pump technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, bioreactors/fermenters for specific purposes, etc., can solve the problem of high power consumption, complex manufacturing process and difficult integration and other problems, to achieve the effect of reducing production cost, easy integration, and simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

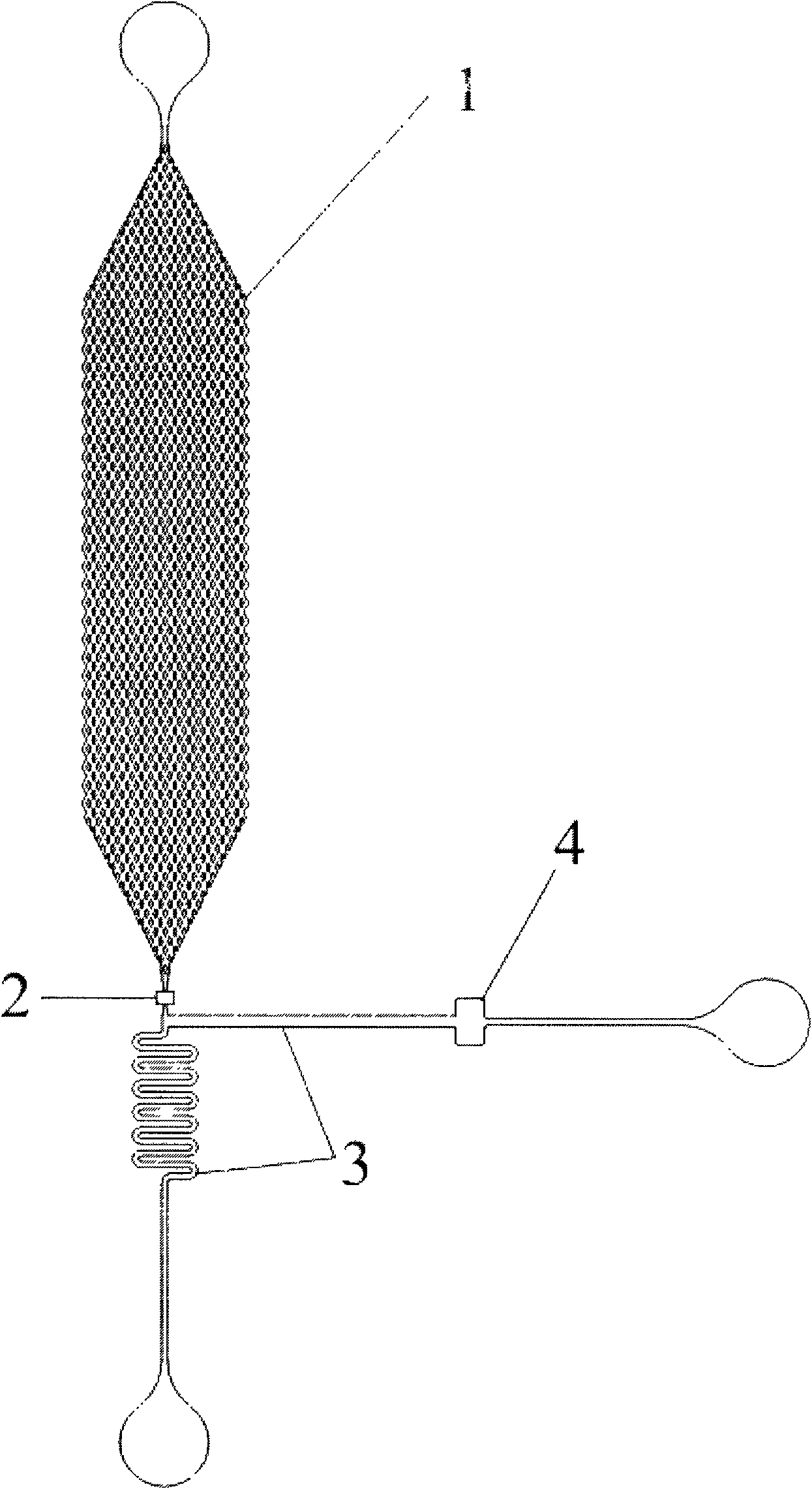

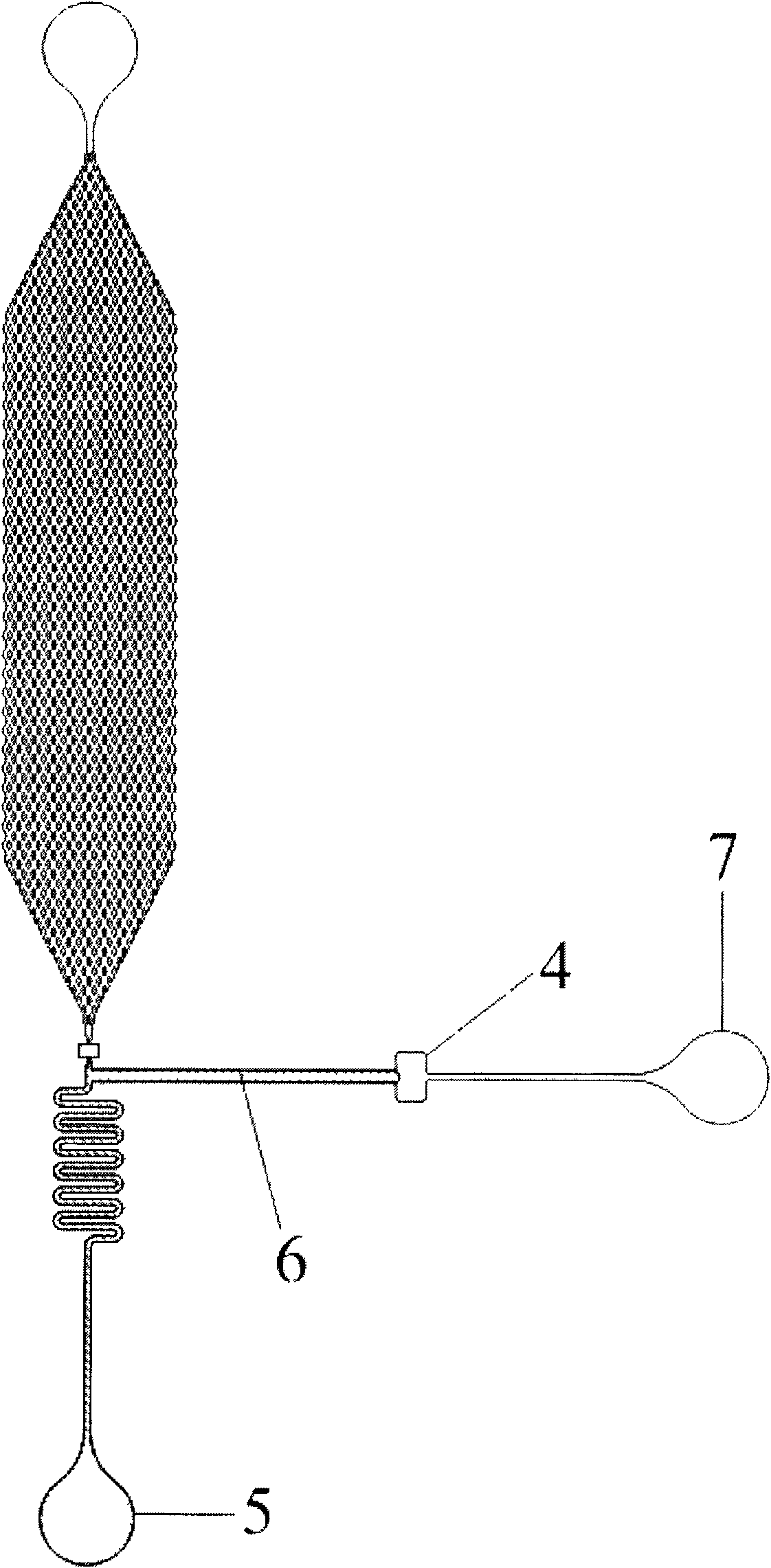

[0016] Such as figure 1 As shown, the main body of a micropump based on capillary action proposed by the present invention includes a micropipeline network 1 as a pump chamber, a partition valve 2 , a sample feeding micropipe 3 and a liquid storage microcavity 4 . The micropump can be applied to the cultivation and observation of a very small amount of cells or bacteria. The specific working process is as follows:

[0017] First, the culture solution 6 containing the cells or bacteria to be cultured is dropped into the inlet 5, and the culture solution is used to automatically fill the sampling micropipe 3 by capillary force. During the filling process of the culture solution, the original air in the sampling pipeline passes through and The air port 7 connecting the sampling micropipe and the liquid storage microcavity is discharged. When the culture solution advances to the connection between the sampling micropipe 3 and the separation valve 2 or the liquid storage microchamb...

Embodiment 2

[0019] The present invention proposes that the capillary micropump can also realize quantitative micro-mixing or micro-reaction through double-body combination. The following is a combination of double-body capillary micropumps applied to protein crystallization to illustrate its characteristics and usage methods. The specific process is as follows:

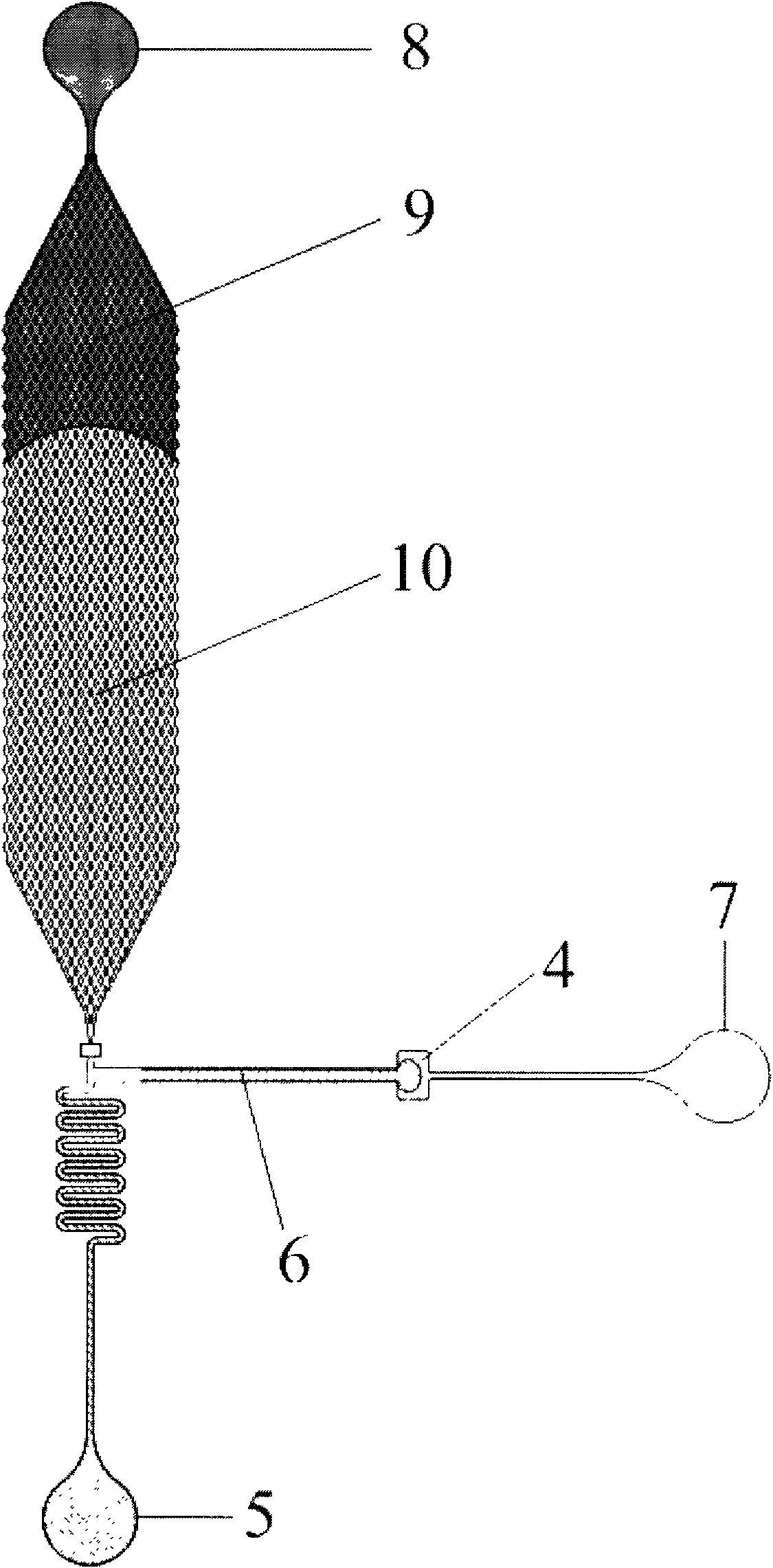

[0020] First, the protein liquid 11 and the crystallization reagent 12 are respectively dropped into the two inlets of the conjoined capillary micropump. The injection and control methods are similar to those in Example 1, and the capillary force and capillary valve are also used to realize the two liquids. autofill and stop of the (eg Figure 4 shown); then, at the two inlets of the capillary pump cavity (i.e. the micropipeline network) of the two-body combination, the driving liquid 9 is dripped at the same time, and the driving method is similar to that of Example 1, and the capillary action is used to compress the liquid in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com