Energy-saving ammonia-nitrogen wastewater treatment method and device

An ammonia nitrogen wastewater and treatment device technology, which is applied in the field of ammonia nitrogen treatment, can solve the problems that the effluent cannot meet the national first-level or second-level discharge standards, the requirements for pretreatment of effluent are harsh, and the cost of treatment chemicals is high. The effect of high safety performance and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

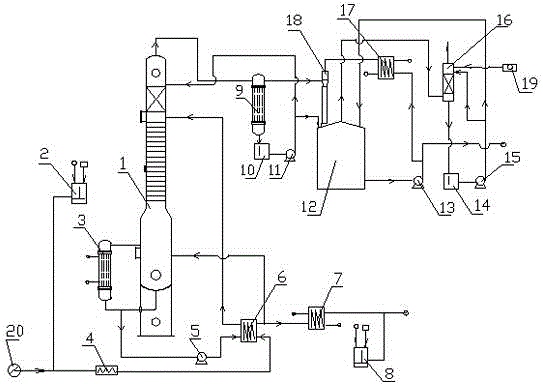

Image

Examples

Embodiment Construction

[0027] The processing method step of the present invention is:

[0028] 1. First add the composite ammonia decomposition catalyst and sodium hydroxide to the ammonia nitrogen wastewater to adjust the pH value to 10.5-11.5 (the pH value of the effluent is not lower than 9.0), and then mix it with the feed mixer and send it to the feed heat exchanger for further processing. Heat exchange and temperature rise, decompose the combined ammonia in ammonia nitrogen wastewater into free ammonia, make ammonia escape from the wastewater quickly under operating conditions, and then transport it to the upper part of the deamination tower and flow to the lower part, and at the same time pass through the reboiler from the deamination tower Steam is delivered to the lower part of the ammonia tower, so that the ammonia nitrogen wastewater and high-temperature steam are in vapor-liquid contact in the medium in the deammonization tower. Then discharge the deamination wastewater;

[0029] 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com