Thermal power generation system with function of exhaust steam recovery

A technology for thermal power generation and spent steam recovery, which is applied in steam application, energy industry, steam engine installations, etc., can solve the problems of unsolvable cooling source loss of condenser, unutilized heat, and low efficiency, so as to solve the problem of thermal pollution. problems, significant energy saving and emission reduction, and the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

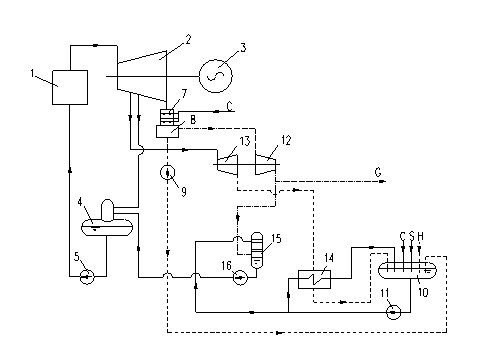

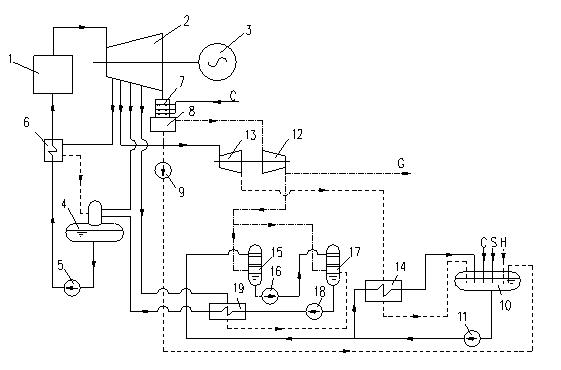

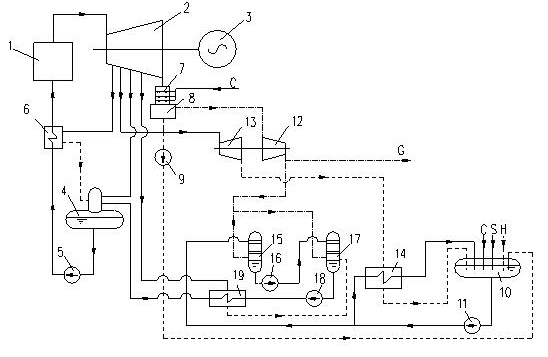

[0018] The idea of the present invention is to use a centrifugal steam compressor to recover exhausted steam, and divide the boosted exhausted steam into two channels: one for external heating, and one for sending into a membrane type steam-water mixing heater to mix and exchange heat with condensed water. The hot water is used as boiler feed water. After booster pump boosts the pressure, it passes through deaerator and feed water pump to the boiler.

[0019] see figure 1 , the present invention consists of a boiler 1, a steam turbine 2, a generator 3, a deaerator 4, a feed water pump 5, a water spray cooling device 7, a steam exhaust heat well 8, a heat well condensate pump 9, a closed pressure condensate tank 10, a main Condensate pump 11, centrifugal steam compressor 12, small steam turbine 13, small steam turbine exhaust steam cooler 14, membrane type steam-water mixing heater 15, booster water pump 16. The working process of the present invention is as follows: the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com