Condensate pump

a condensate pump and condensate technology, applied in the direction of positive displacement liquid engines, heating types, lighting and heating apparatuses, etc., can solve the problem of reliability over many years, and achieve the effect of reducing maintenance requirements, preventing vibration transmission, and being easy to observ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

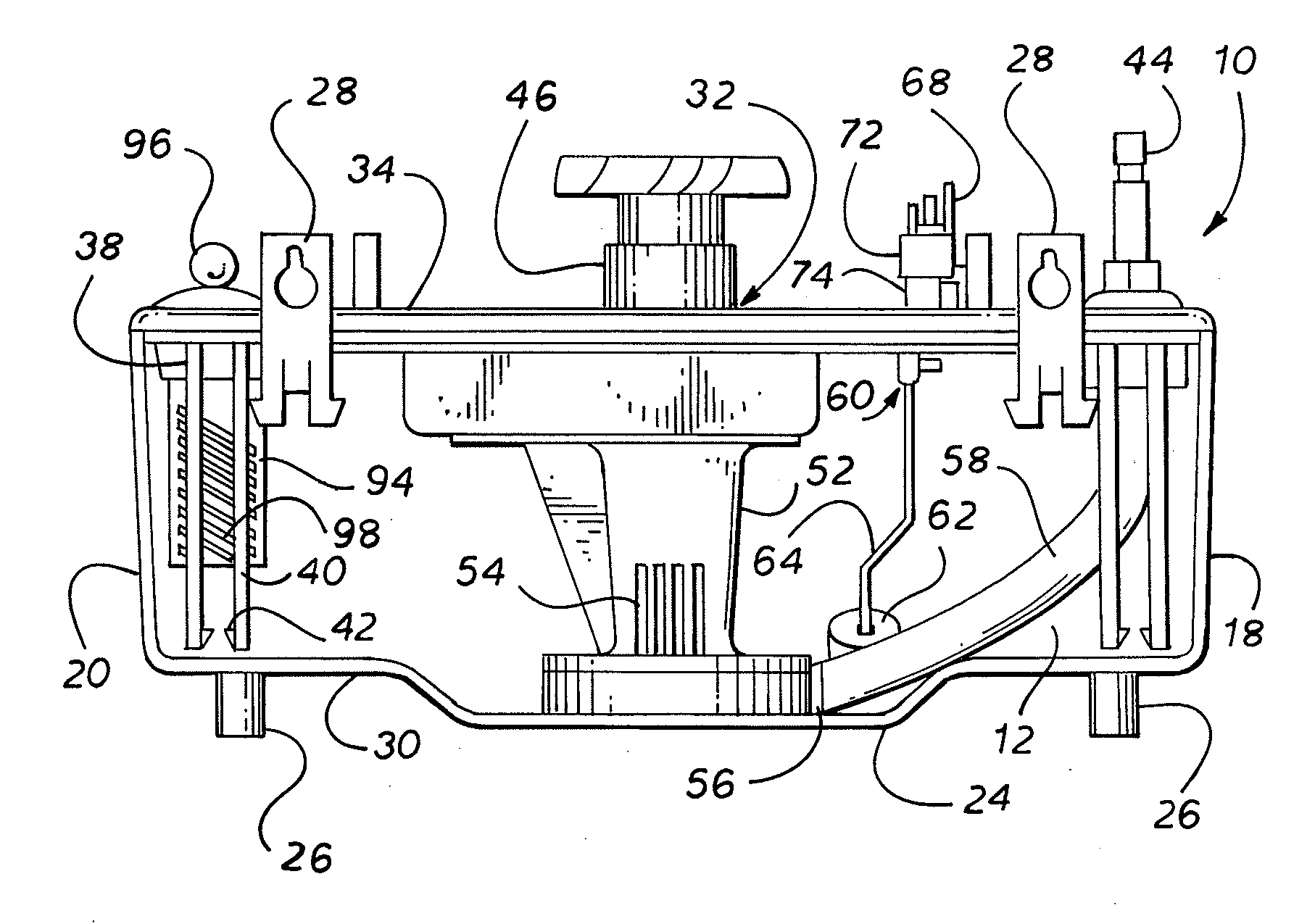

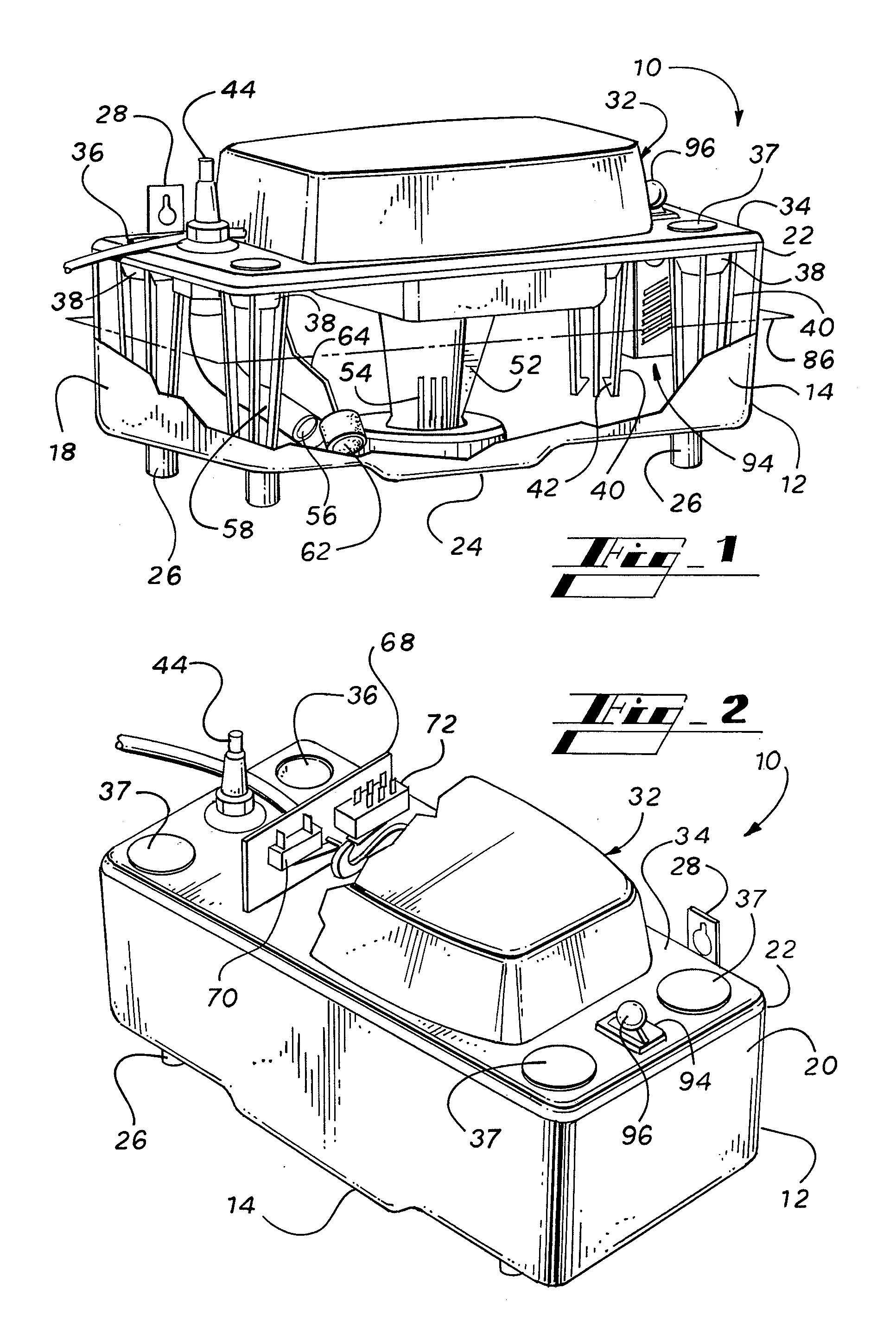

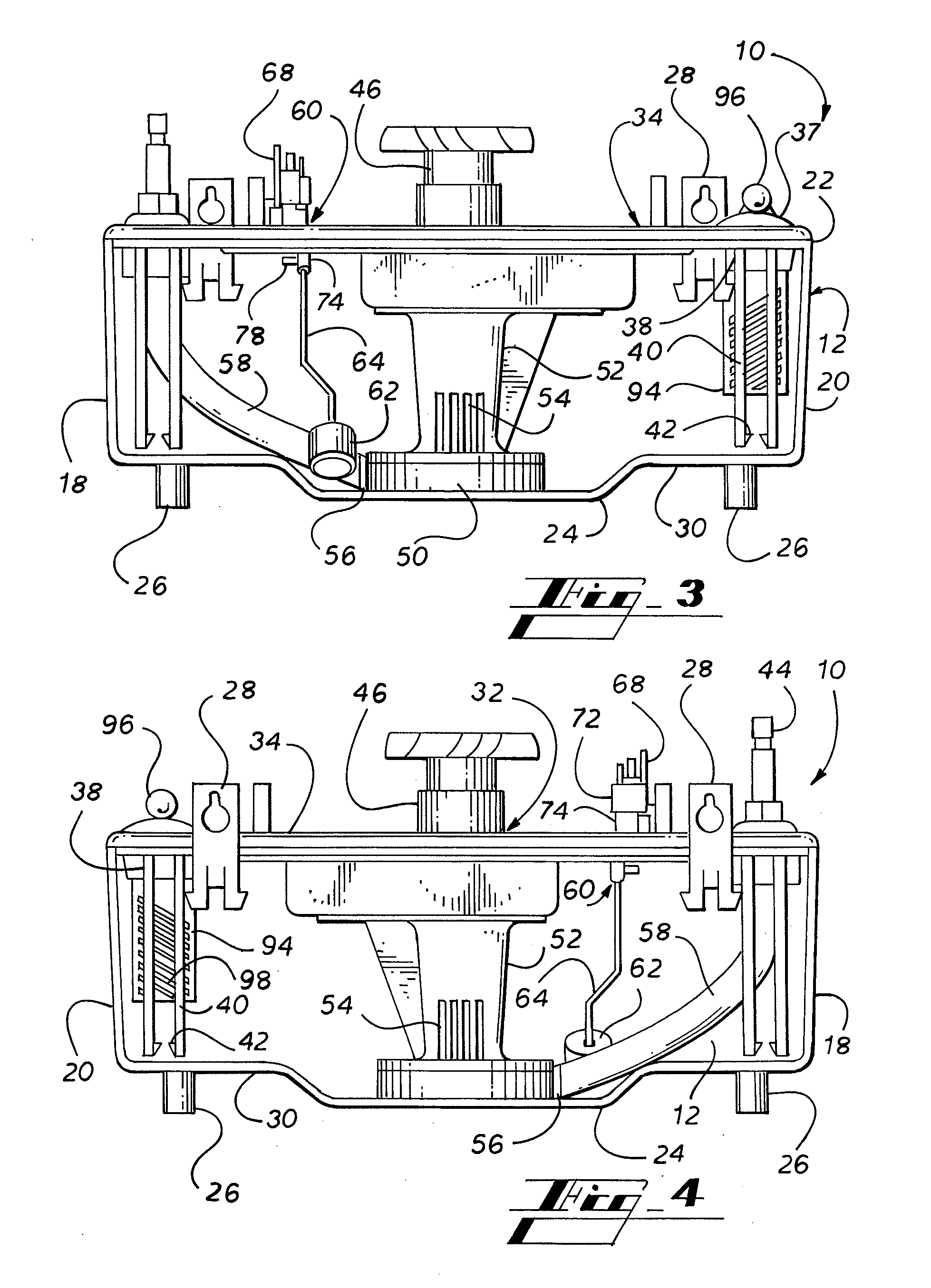

[0020] Turning to FIG. 1, a condensate pump 10 comprises a reservoir 12 and a top assembly 32. The reservoir 12 comprises a water tight container with an open top defined by a periphery. In on embodiment the reservoir comprises a front panel 14, a back panel 16, a left side panel 18, a right side panel 20, and a bottom panel 30. The reservoir may be of any geometric shape. The reservoir 12 has rubber support legs 26 located on the four corners of the bottom panel 30. The reservoir 12 further has a flange 22 around the top periphery on which the top assembly 32 rests. In addition, hanger brackets 28 are mounted to the reservoir on the back panel 16. The hanger brackets 28 are used to mount the reservoir 12, on a wall or other elevated support in order to make later access to the condensate pump 10 in some cases easier. The reservoir 12 is constructed of a clear plastic material, such as polypropylene, so that the water level in the reservoir can be observed without removing the top a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com