Coal-fired power generation and waste heat power generation coupling system for private station of cement kiln

A waste heat power generation and power generation system technology, applied in cement production, waste heat treatment, mechanical equipment, etc., can solve problems such as increased operational difficulty, increased initial investment, and complex structure of single-pressure steam turbines, and achieves improved thermoelectric conversion efficiency and reduced coal consumption. The effect of less quantity and saving one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

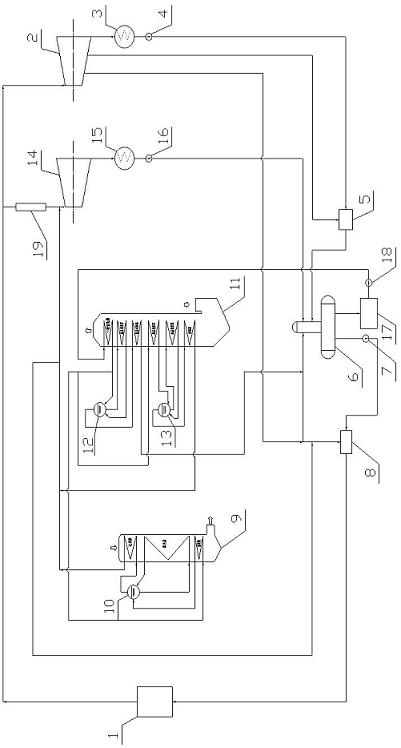

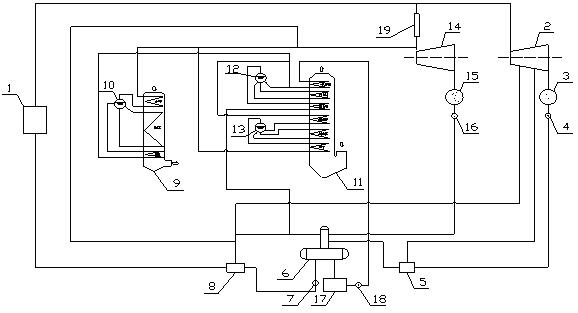

[0017] The structure of this embodiment is as figure 1 As shown, a coupling system for coal-fired power generation and waste heat power generation in a cement kiln self-contained power station includes a coal-fired boiler 1, a coal-fired power generation condensing steam turbine 2, a condenser 3, a condensate pump 4, a low-pressure heater 5, and an oxygen removal 6. Electric feed water pump 7. High pressure heater 8. Waste heat boiler at kiln tail 9. Steam drum at kiln tail 10. Waste heat boiler at kiln head 11. Low pressure steam drum at kiln head 12. Steam drum at kiln head 13. Waste heat turbine 14. Waste heat power generation Condenser 15, waste heat power generation condensate pump 16, intermediate water tank 17, feed water pump 18, temperature and pressure reducer 19.

[0018] The following procedures are described below:

[0019] (1) The working process of cement kiln waste gas waste heat: the cold air exchanges heat with clinker in the grate cooler of the cement kiln ...

Embodiment 2

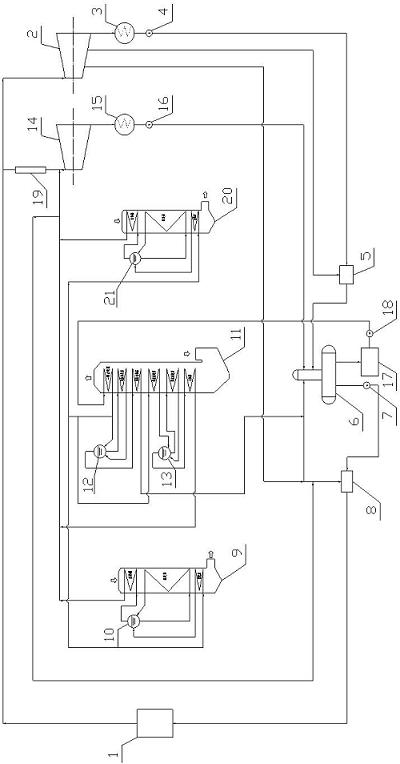

[0024] The structure of this embodiment is as figure 2 As shown, it is described in the following steps:

[0025] (1) The working process of the exhaust gas is as follows: a bypass air pipe is introduced at the end of the cement kiln, and the air volume accounts for about 15% of the total air volume. After heat exchange, the working medium in the waste heat boiler 20 is recycled to equipment such as cement kiln raw material mill and coal mill for further utilization.

[0026] (2) The working process of the circulating working fluid: the circulating working medium is pressurized by the intermediate water tank 17 and then by the feed water pump 18. After the pressurization, there are two water supply channels, and the other is the first-level economizer leading to the waste heat boiler 11 at the kiln head. The other road leads to the economizer of the waste heat boiler 20 at the kiln tail, and generates superheated steam after exchanging heat with the hot air drawn from the by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com