Cogeneration system by firing coil assisted by biomass and solar energy

A combined power generation and power generation system technology, applied in solar thermal power generation, solar heating systems, solar thermal energy, etc., can solve the problems of large harmful gas emissions, low energy utilization rate, high coal consumption, etc., to reduce coal consumption and improve gasification efficiency , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

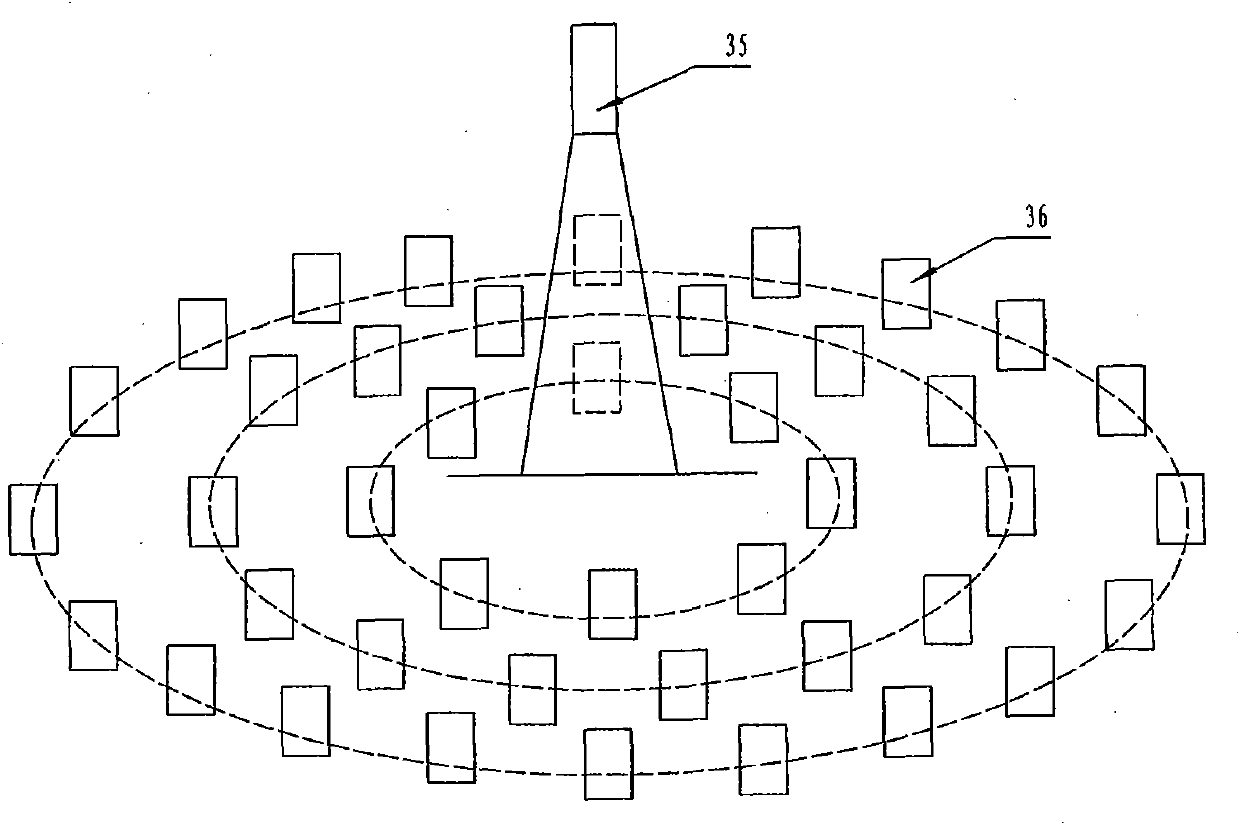

[0023] The invention provides a coal-fired combined power generation system assisted by biomass and solar energy. The system consists of a coal-fired boiler, steam turbine, generator, condenser, condensate pump, deaerator, drain pump, feed water pump, heater, series auxiliary system and tower solar air preheating system, in which the series auxiliary system consists of The biomass gasification device is connected in series with the parabolic trough solar heat collector field; the tower solar air preheating system is composed of a compressor and a tower solar heat collector in series.

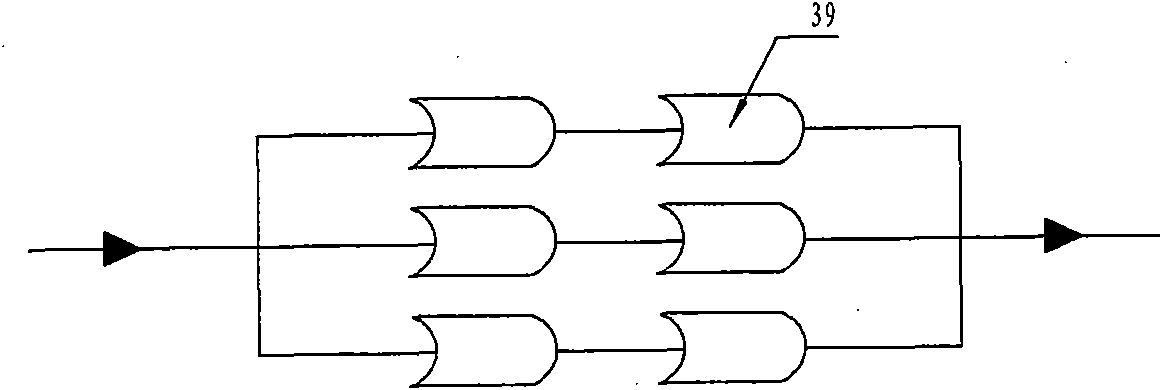

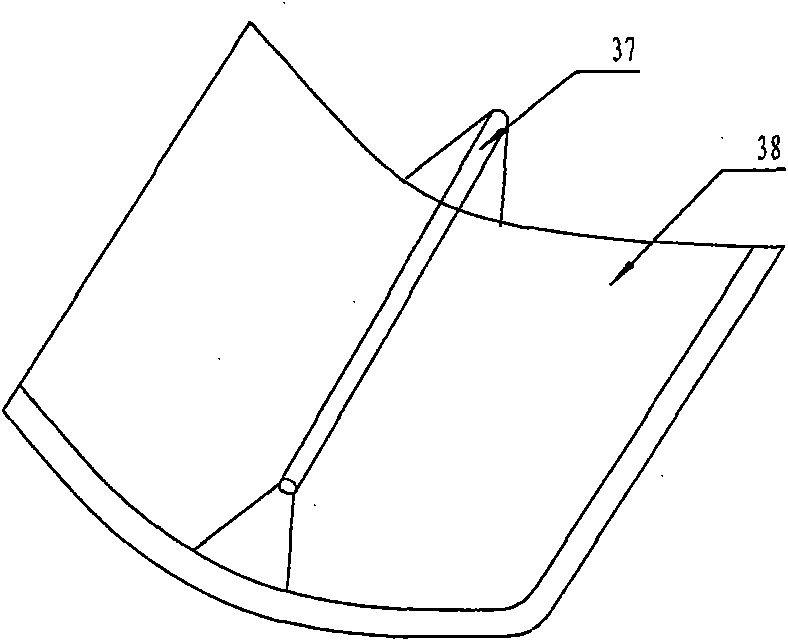

[0024] see figure 2 , image 3 , the parabolic trough solar heat collector field is composed of parabolic trough solar heat collectors 39 connected in series and in parallel. The main structure of the parabolic trough solar heat collector 39 is a parabolic trough concentrator 38 and a heat exchange tube 37. What flows in the heat exchange tube 37 is a heated working fluid, and the parabolic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com