Air-breathing pulse detonation engine and detonation method thereof

A pulse detonation and engine technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve performance loss, pneumatic valve forward flow resistance and reverse flow control can not be solved well, large frontal area and other problems , to achieve the effect of simple structure, shortened length and improved engine thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

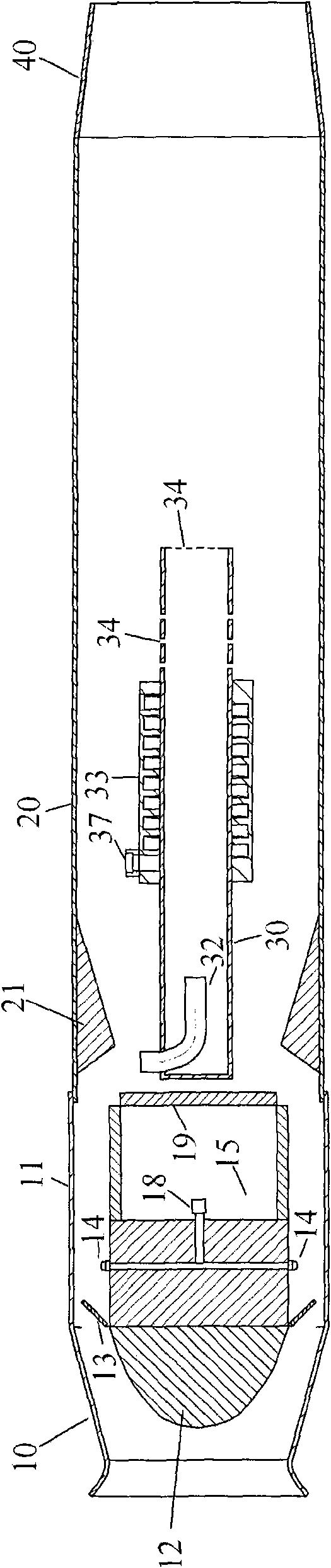

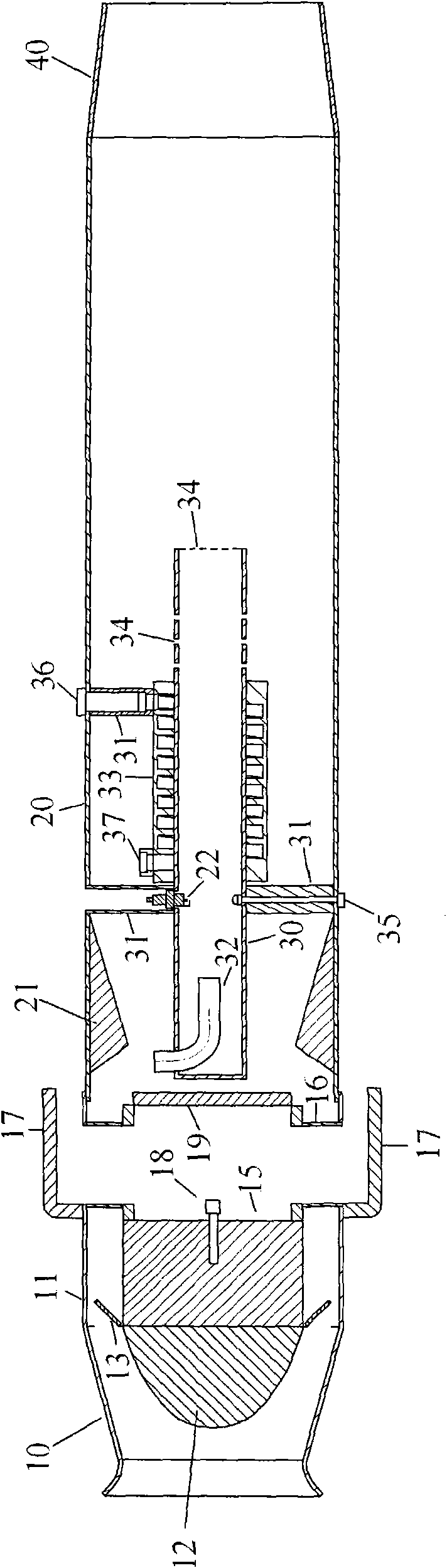

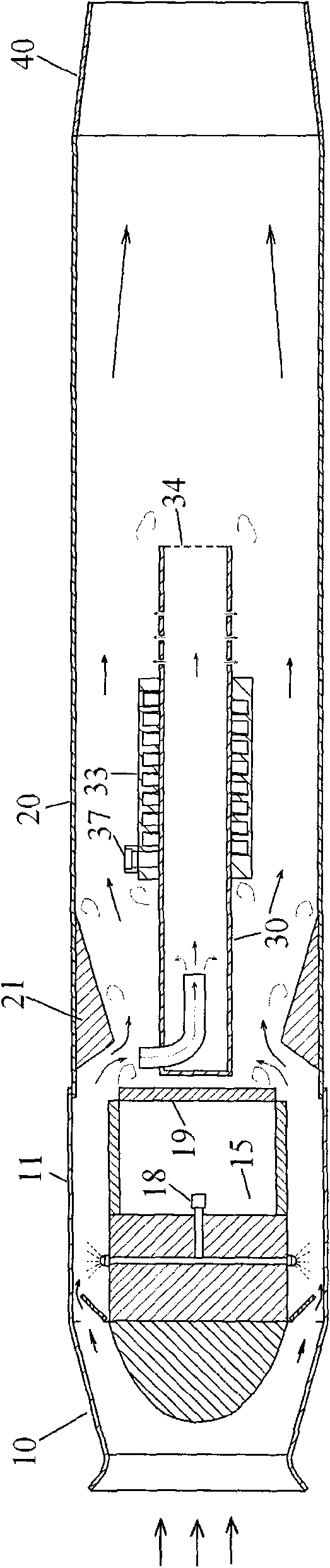

[0035] The engine has two sets of mutually independent intake and oil inlet systems, an intake duct, a detonation chamber, a detonator and a tail nozzle. The intake duct 10 is located at the front end of the engine, with the opening forward, as shown in Figure 1(a), including Inlet casing 11, air inlet central body 12, reed valve 13, main fuel nozzle 14, air release chamber 15, air release pipe 17 and main fuel nozzle oil inlet 18, central body support 16 and main fuel nozzle 14 distribution At different circumferential positions, hence no centrosome support in Fig. 1. In another direction (rotated by 90°) in the sectional view 1(b), the air inlet housing 11 is connected to the air inlet central body 12 through a plurality of central body brackets 16 uniformly distributed around the circumference. The air intake casing 11 is fixed, and the size of the air intake ring cavity can be adjusted by adjusting the front and rear axial positions of the air intake central body 12, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com