Combined pulse detonation engine detonation chamber

A technology of pulse detonation and engine, which is applied in mechanical equipment, intermittent injection devices, etc., can solve the problems that the shock wave focusing concave cavity is not concave, and does not form high-frequency detonation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is the first preferred solution, the two jet tubes can be ignited in time; that is, the two pre-detonation tubes are sequentially ignited, so that the operating frequency of the main detonation chamber is twice the operating frequency of the pre-detonation tube, thereby extremely Greatly improve the operating frequency of the engine.

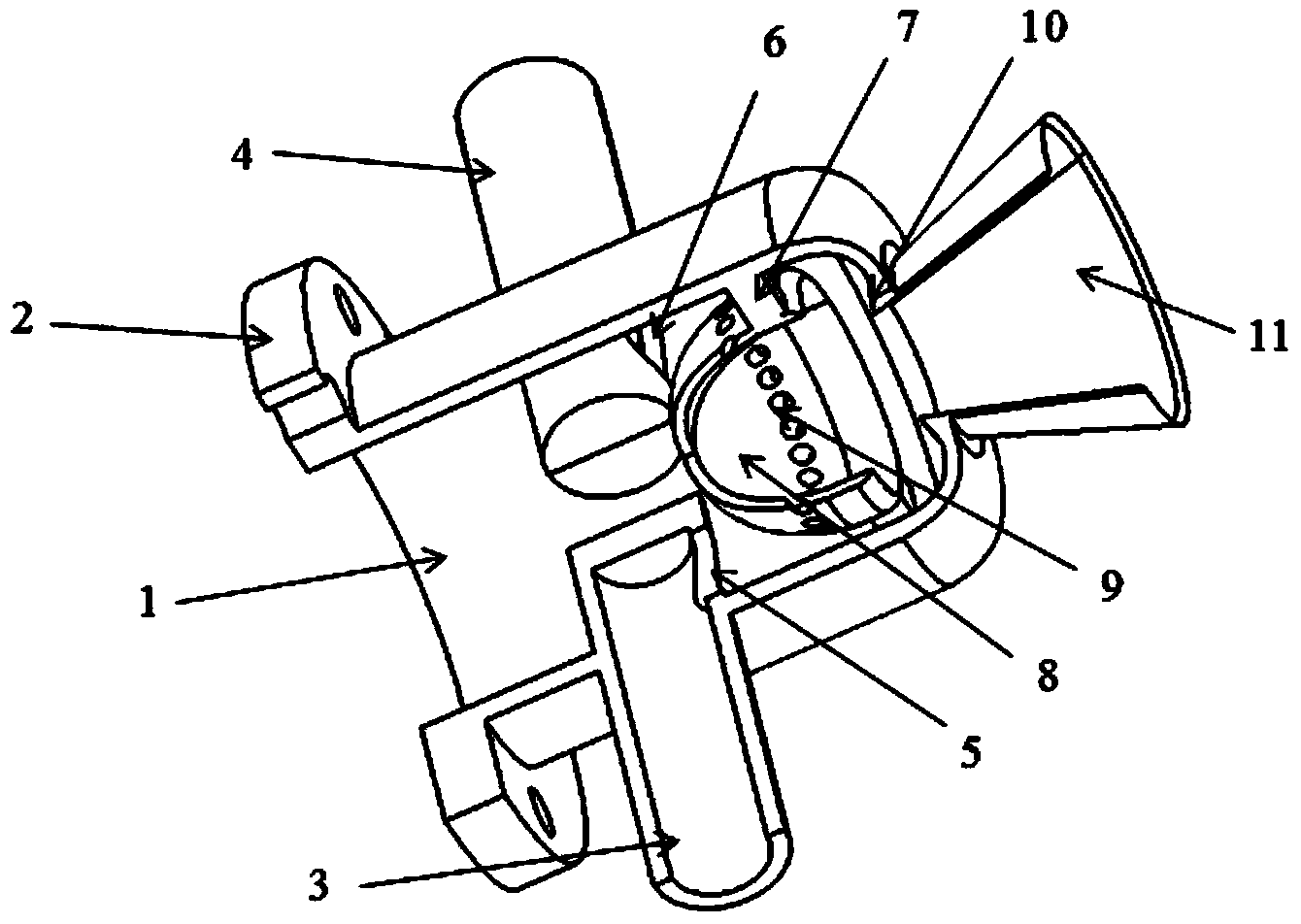

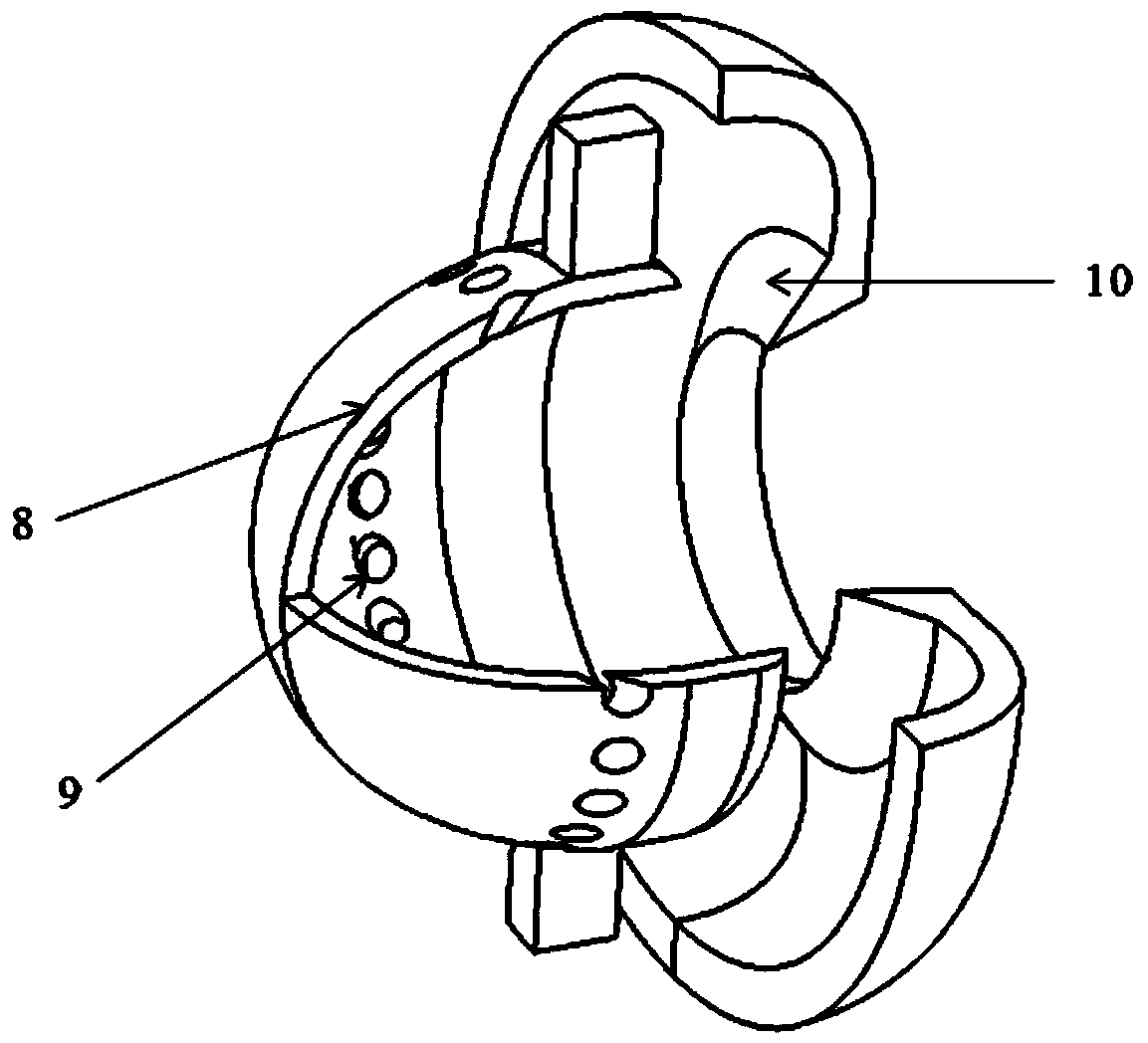

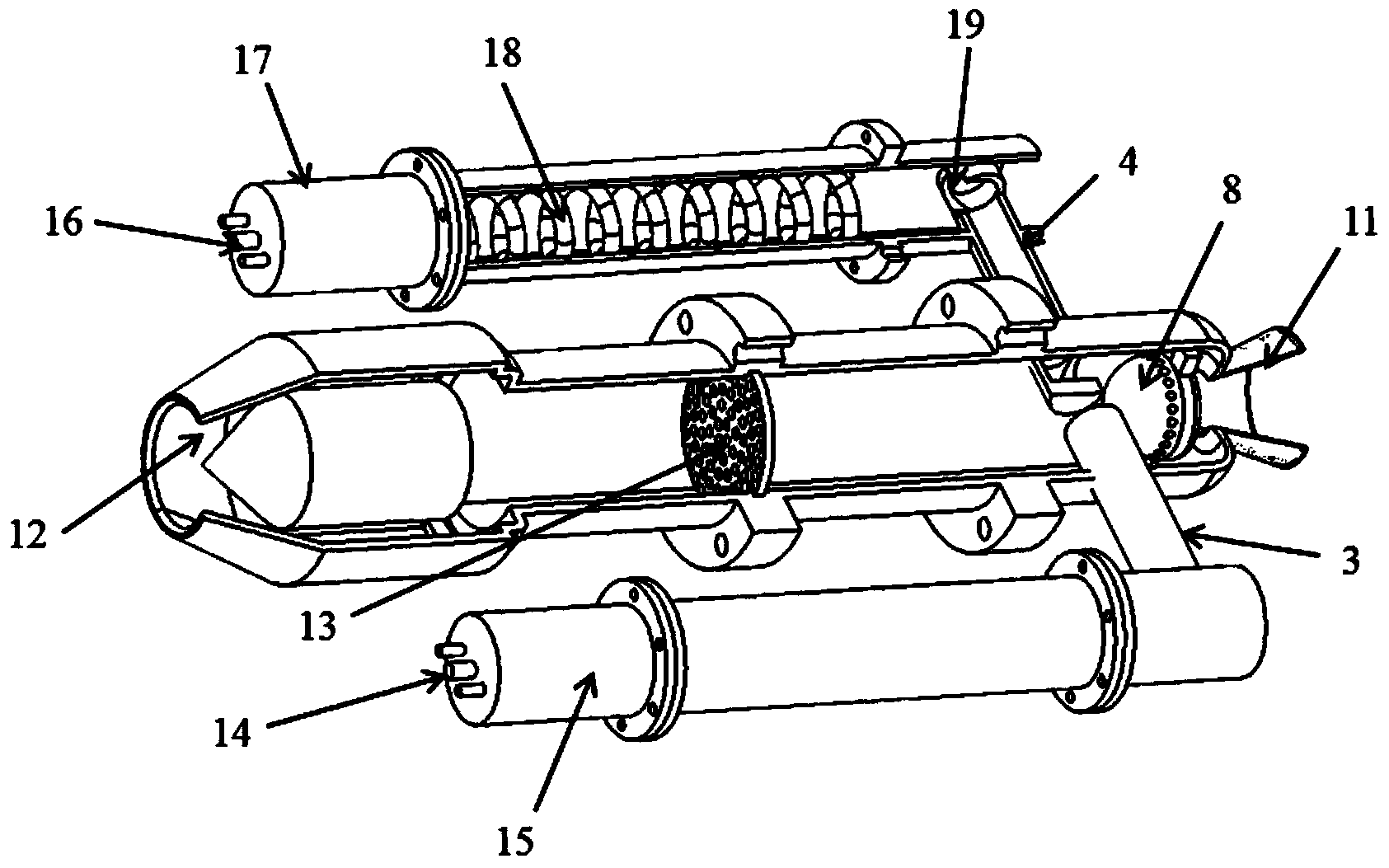

[0022] refer to figure 1 , figure 2 , image 3 , The detonation chamber of the combined pulse detonation engine of this embodiment consists of a main detonation chamber 1, a flange 2, a first jet pipe 3, a second jet pipe 4, a first jet pipe outlet 5, and a second jet pipe outlet 6 , strut 7, shock wave focusing cavity 8, oblique jet hole 9, deflector ring 10, tail nozzle 11, air inlet 12, orifice plate 13, first pre-explosion tube fuel inlet 14, first pre-explosion tube 15. The second pre-detonation tube fuel inlet 16, the second pre-detonation tube 17, the detonation enhancement device 18, the detonation jet drainage...

Embodiment 2

[0026] like Figure 4As shown, as the second preferred solution of the present invention, the number of jet tubes can be multiple, and a cross-symmetrical layout is formed with the engine 20 as the central axis under the permission of the space size. This cross-symmetrical layout can ensure the formation of detonation waves. In addition, more jet tubes can be divided into multiple groups, and each group of jet tubes is sequentially ignited to work. The operating frequency of the main detonation chamber of the engine is the operating frequency of the pre-explosion tube multiplied by the number of groups, thereby greatly increasing the operating frequency of the engine. In this embodiment, the four pre-explosion tubes are divided into two groups, and the two groups of pre-explosion tubes are fixed in a cross-symmetrical manner. The two opposite pre-explosion tubes form a group. And the filling of oxidant, so as to precisely control the ignition of the main detonation chamber 1....

Embodiment 3

[0028] As a third preferred solution of the present invention, the jet tube is arranged in a ring around the main detonation chamber 1, and this ring layout makes the pre-explosion tube a small booster engine, which is used as a booster device for supersonic flight of the engine.

[0029] When the detonation chamber of the combined pulse detonation engine of the present invention was working, the pre-explosion tube became a system independently, and the fuel and The oxidant is precisely controlled by the solenoid valve to realize accurate control of the ignition time of the main detonation chamber 1. The main detonation chamber 1 starts to fill the main detonation chamber 1 with the fully mixed and atomized fuel-air mixture within the unit working cycle. When the main detonation chamber 1 is filled, the detonation wave formed by the pre-detonation tube passes through the first jet tube 3 And the second jet tube 4 starts firing the main detonation chamber. A deflagration wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com