Internal explosion experiment based test method for quantitative evaluation on energy release of thermobaric explosive

A technology of thermobaric explosives and energy release, applied in the direction of material explosiveness, etc., can solve the problems of high test cost, randomness of explosion test, high risk, and difficulty in realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

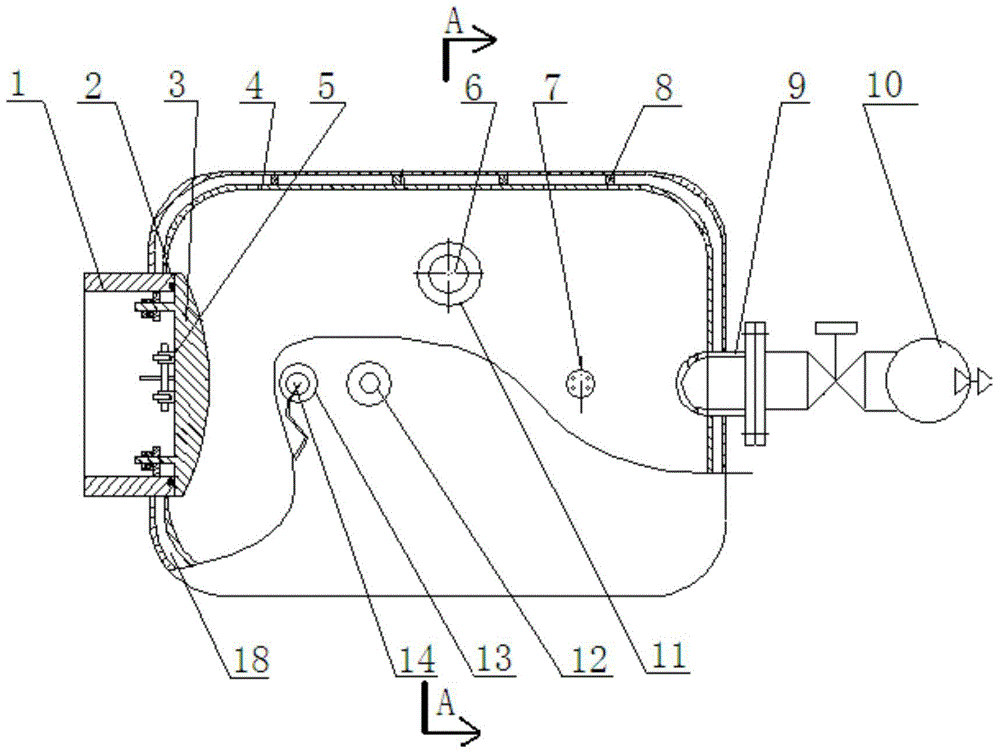

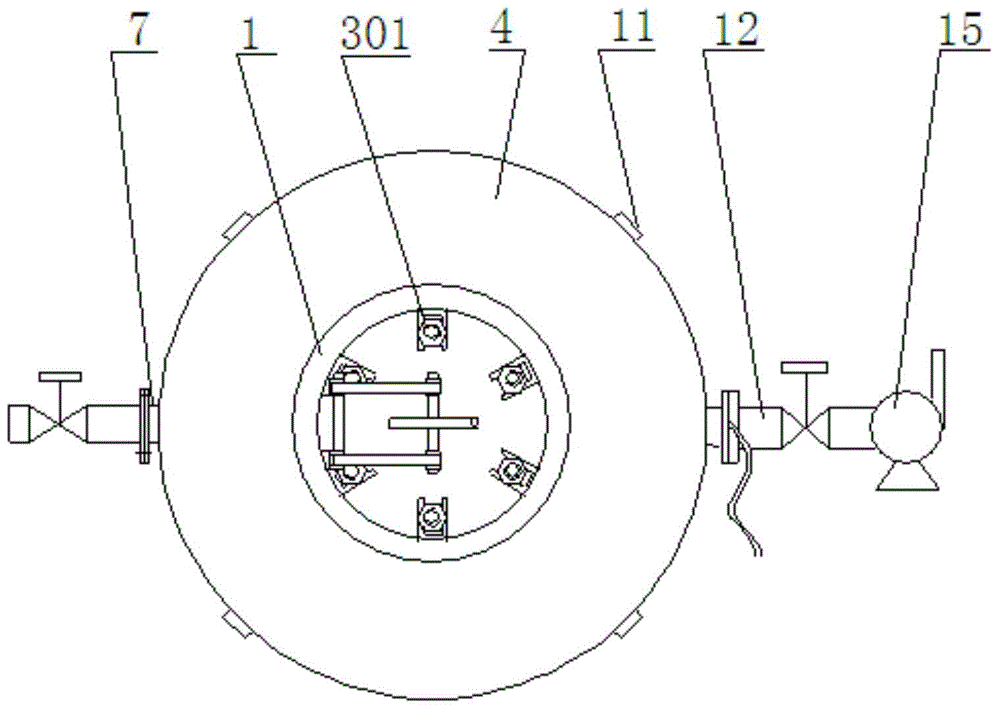

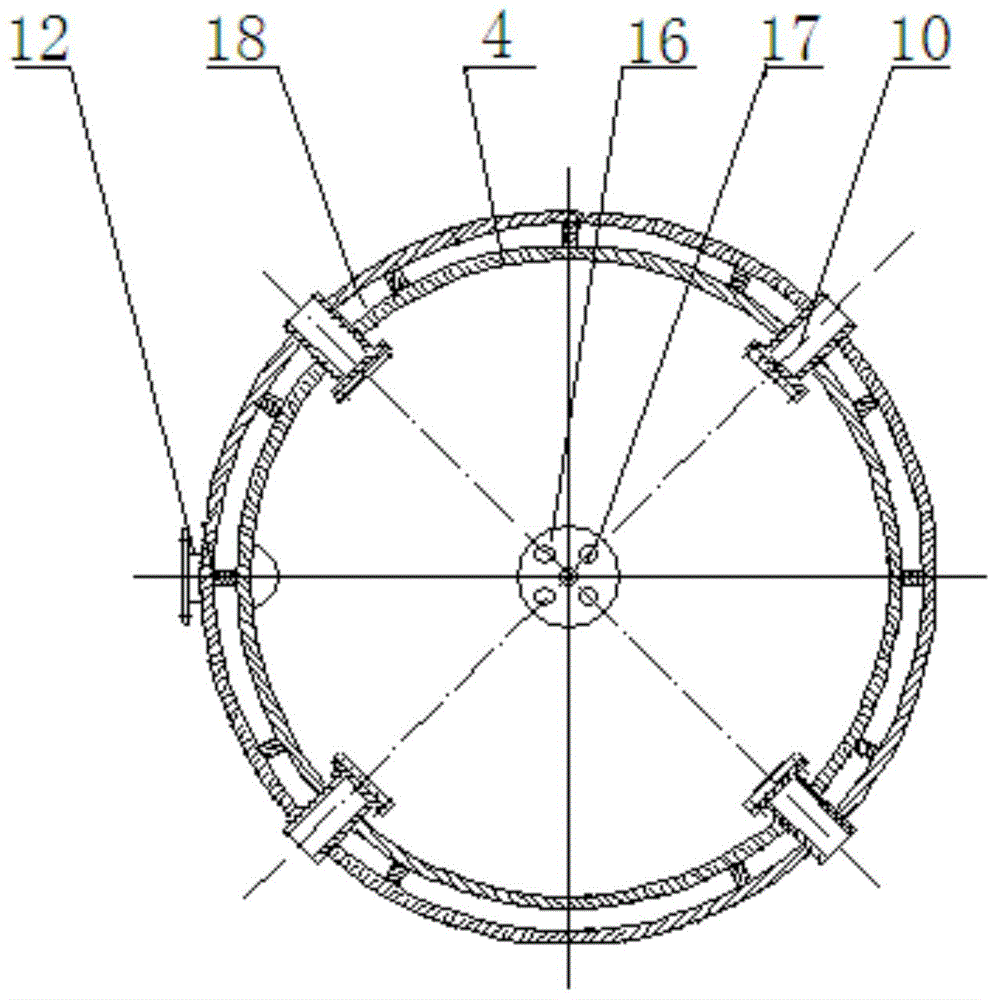

[0142] It should be noted that the inner diameter of the test explosion tank used in this example is φ2.6m, and the volume is 26m 3 , the impact resistance is less than 7kgTNT equivalent; the mass ratio of the test temperature and pressure explosive components is 64.4% HMX, 30% Al, 1.4% fluororubber, 4.2% DOA, and the molecular formula is C 1.242 h 2.410 N 1.870 o 1.451 f 0.05226 Al 1.193 , wherein the valence of the C atom is -4, the valence of the H atom is +1, the valence of the O atom is -2, the valence of the F atom is -1, and the valence of the Al atom is +3, and the TNT equivalent coefficient of the thermobaric explosive is tested is 1.8.

[0143] The present embodiment provides a method for quantitative testing of the energy release of thermobaric explosives based on the internal explosion test, the method comprising the following steps:

[0144] Step 1, the determination of the test device;

[0145] Use the test explosion tank to carry out the internal explosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com