Method for detecting deflagration in coal mill outlet coal dust pipeline, and detection system thereof

A pulverized coal pipeline and detection system technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of incompletely effective, reliable, timely detection, large amount of operation and maintenance, and high price, so as to avoid large-area The effects of equipment burnout, reliable sampling signal, and timely alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. First of all, it should be noted that the present invention is not limited to the following specific embodiments. Those skilled in the art should understand the present invention from the spirit embodied in the following embodiments, and each technical term can be optimized based on the spirit of the present invention. broad understanding. The same or similar components in the figures are denoted by the same reference numerals.

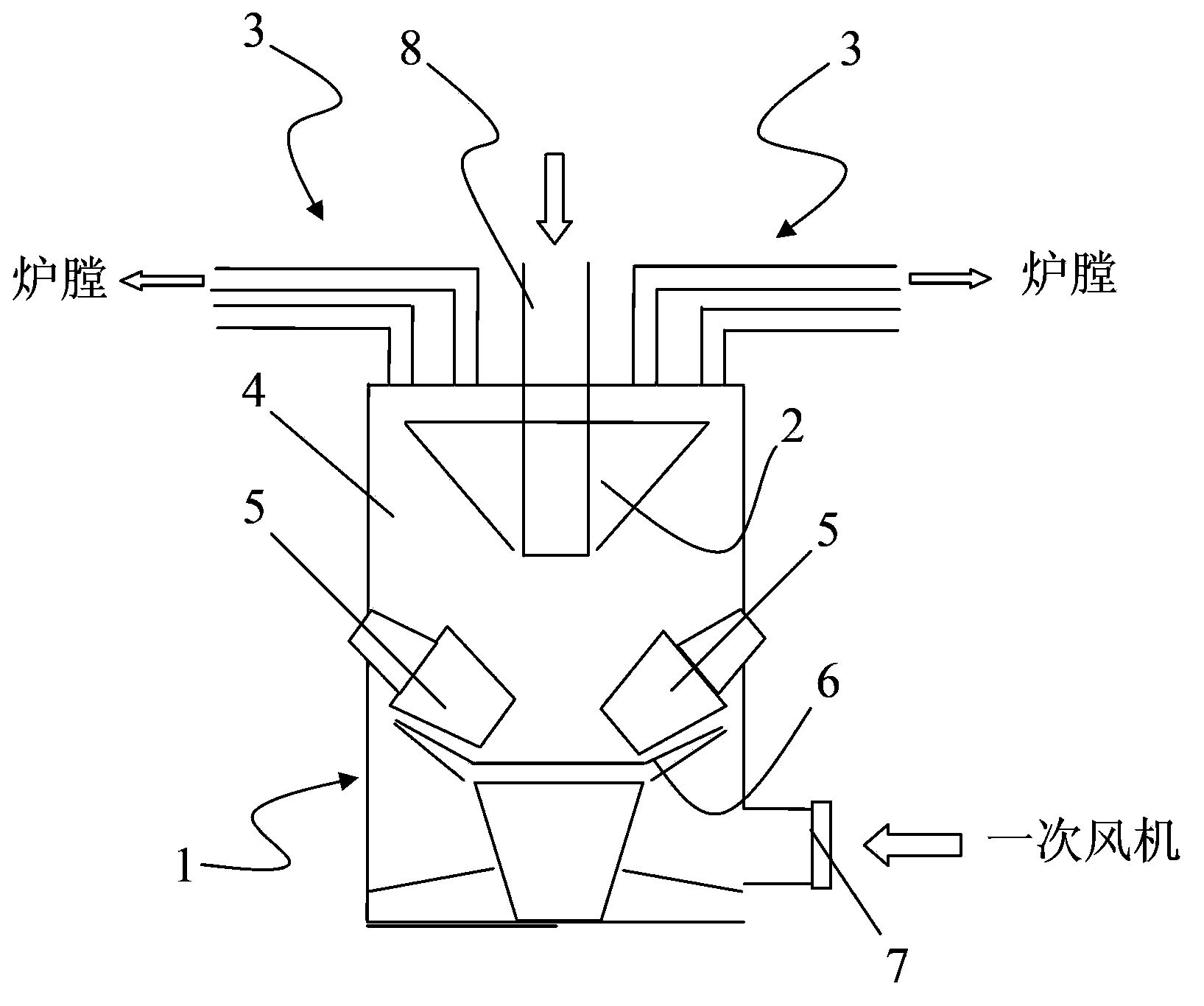

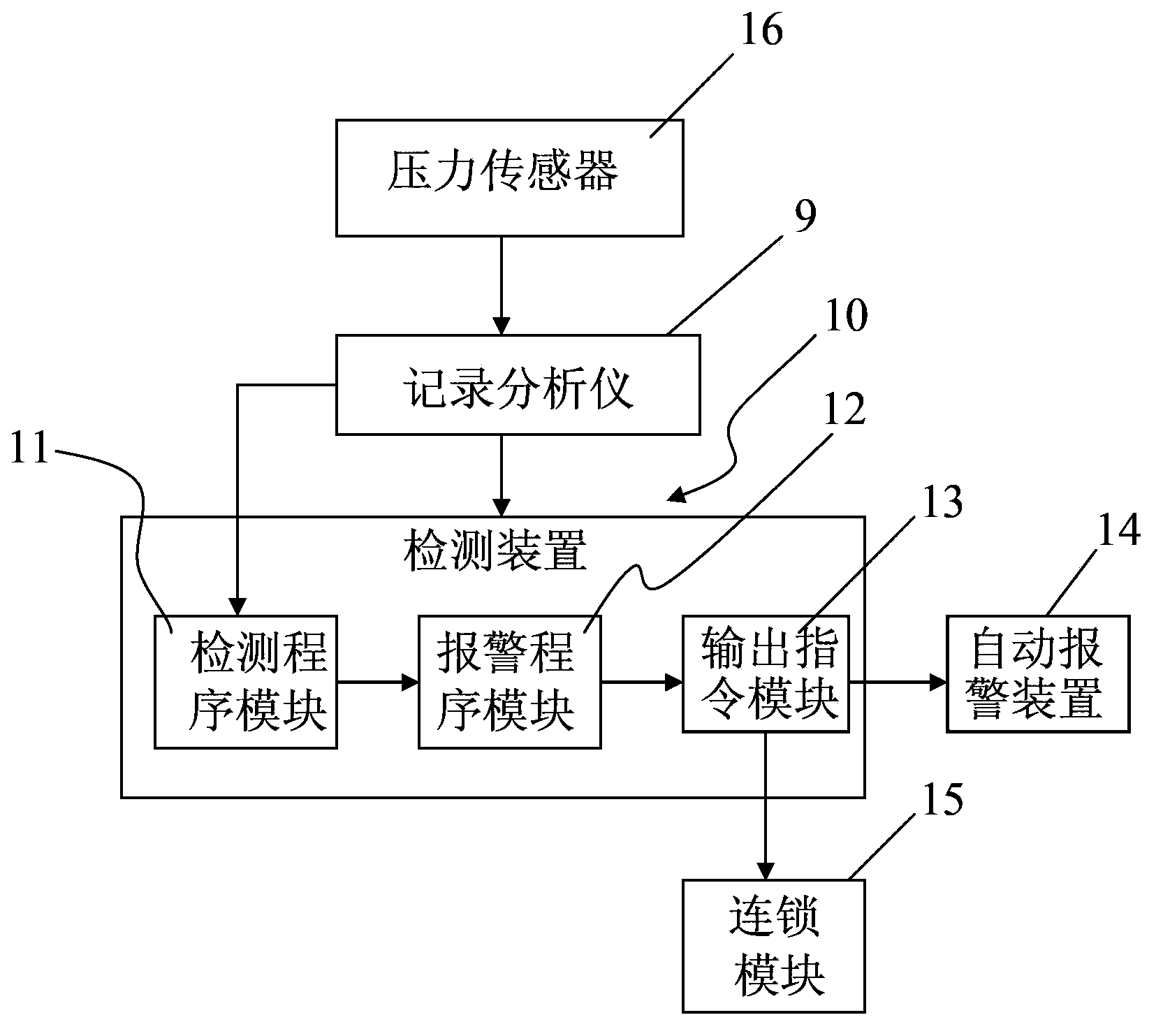

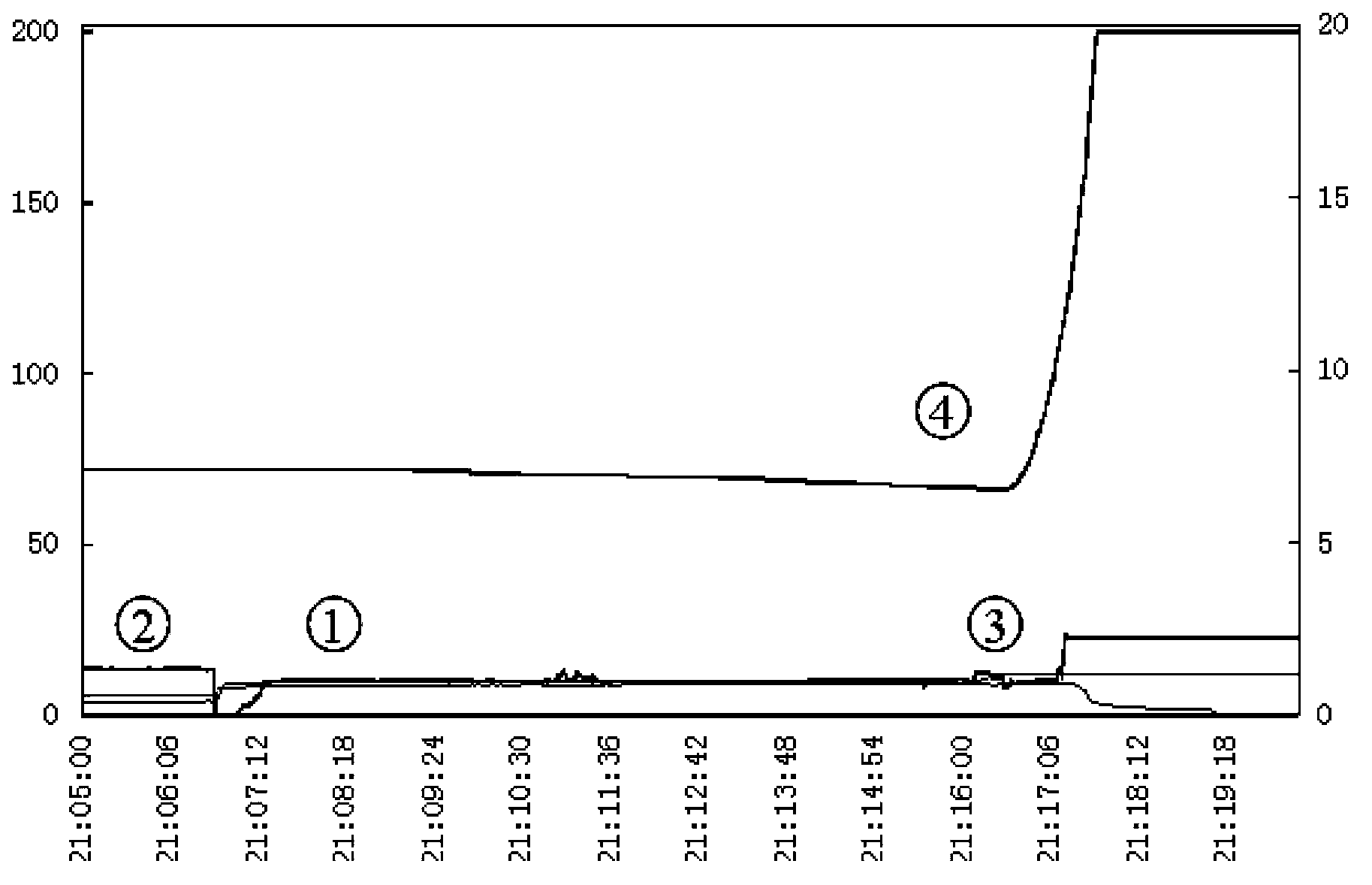

[0031] Coal-fired power plant boiler pulverization system consists of coal storage bunker, coal feeder, coal mill, primary fan, sealing fan and coal powder export pipeline. figure 1 A part of the fat powder system is shown: the coal pulverizer 1 and the pulverized coal outlet conveying pipeline 3 . The coal mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com