Pulse fracturing sand injector for horizontal wells

A pulse pressure, horizontal well technology, used in directional drilling, wellbore/well components, and production fluids, etc., can solve the problems that the fracturing bomb structure is not suitable for the horizontal well body structure, and the fracture is not supported by sand. The effect of increasing production is obvious, prolonging the time of increasing production, and the effect of safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

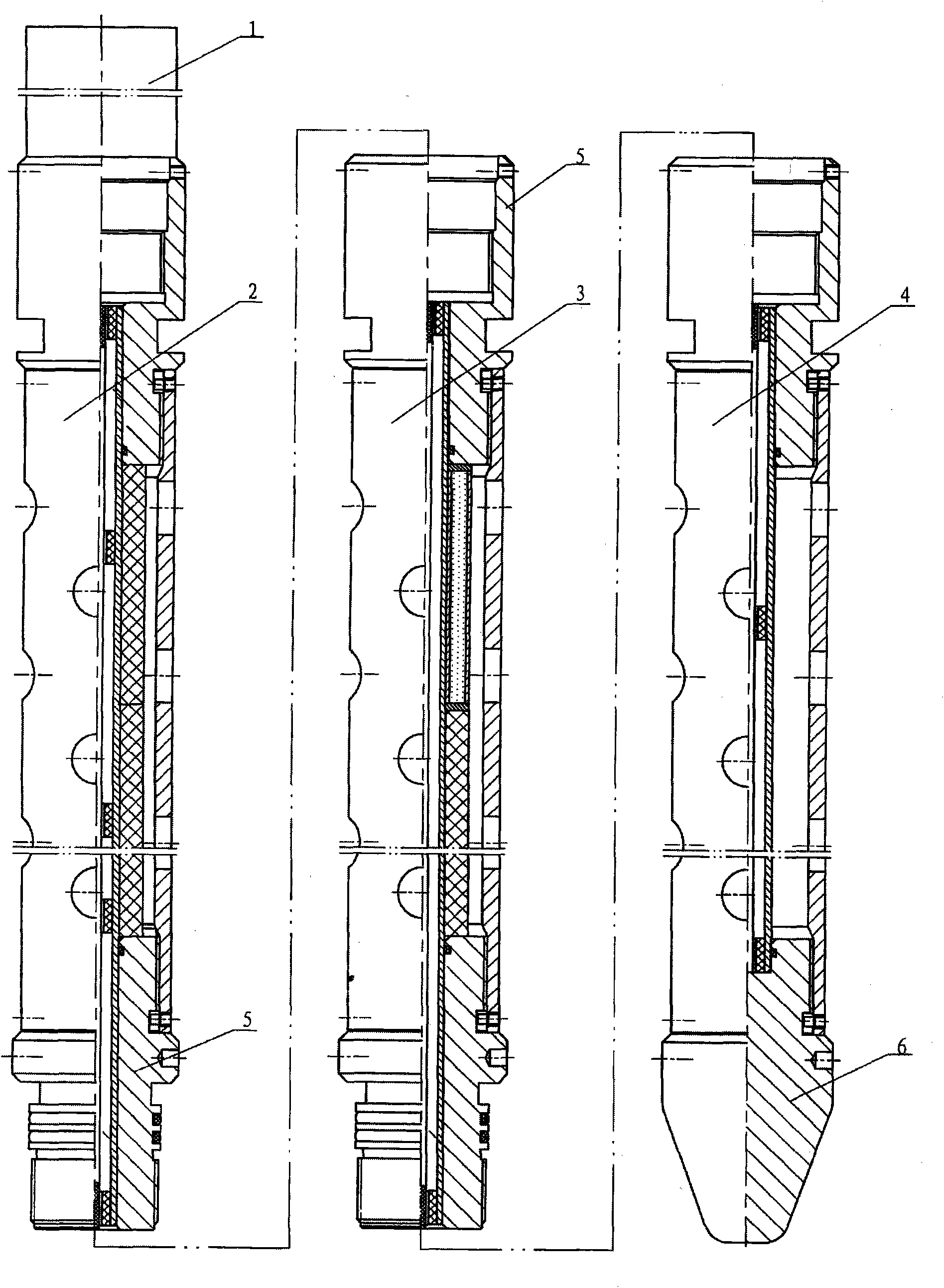

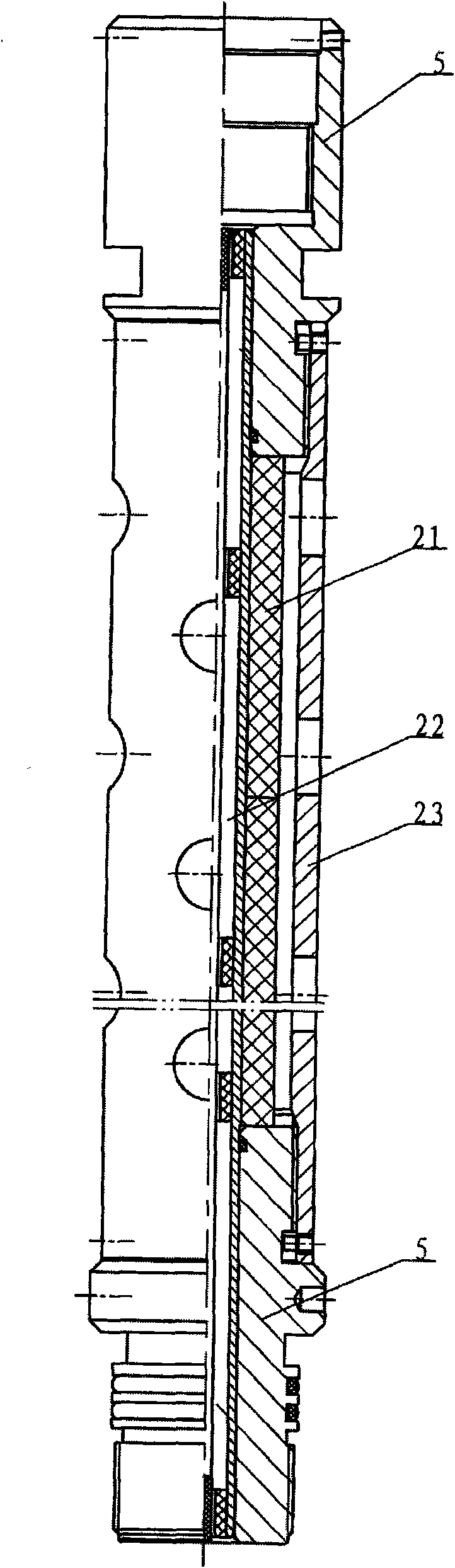

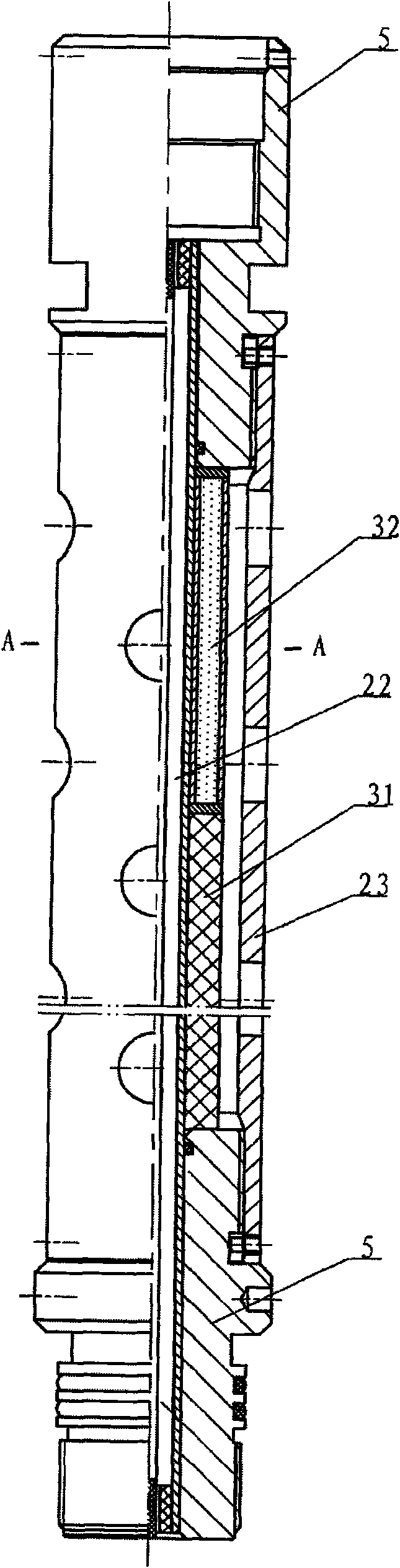

[0019] See attached figure 1 , the horizontal well pulse fracturing sanding device of the present invention is formed by sequentially connecting an igniter 1, a fracturing gun assembly 2, a sanding gun assembly 3, an interlayer gun assembly 4, an intermediate joint 5 and a gun tail 6; The cracking gun assembly 2, the sanding gun assembly 3, the interlayer gun assembly 4 and the intermediate joint 5 are combined into gun bodies of different lengths as required, the fracturing gun assembly 2 is connected to the igniter 1 through the intermediate joint 5, and the gun tail 6 is passed through the intermediate joint 5 is connected with the interlayer gun assembly 4 to form pulse fracturing sand adding devices of different lengths.

[0020] The fracturing gun assembly 2, the sanding gun assembly 3 and the interlayer gun assembly 4 all include a screen tube 23 with the same shape and diameter, and there are evenly distributed through holes on the screen tube 23; the through holes are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com