Safety rapid processing technique for strong zhiji rock burst

A processing technology and technology for rock burst, which is applied in the field of safe and rapid processing technology for strong to extremely strong rock bursts, and can solve the problems of long time, closed arches, and the inability of arches to stick to surrounding rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

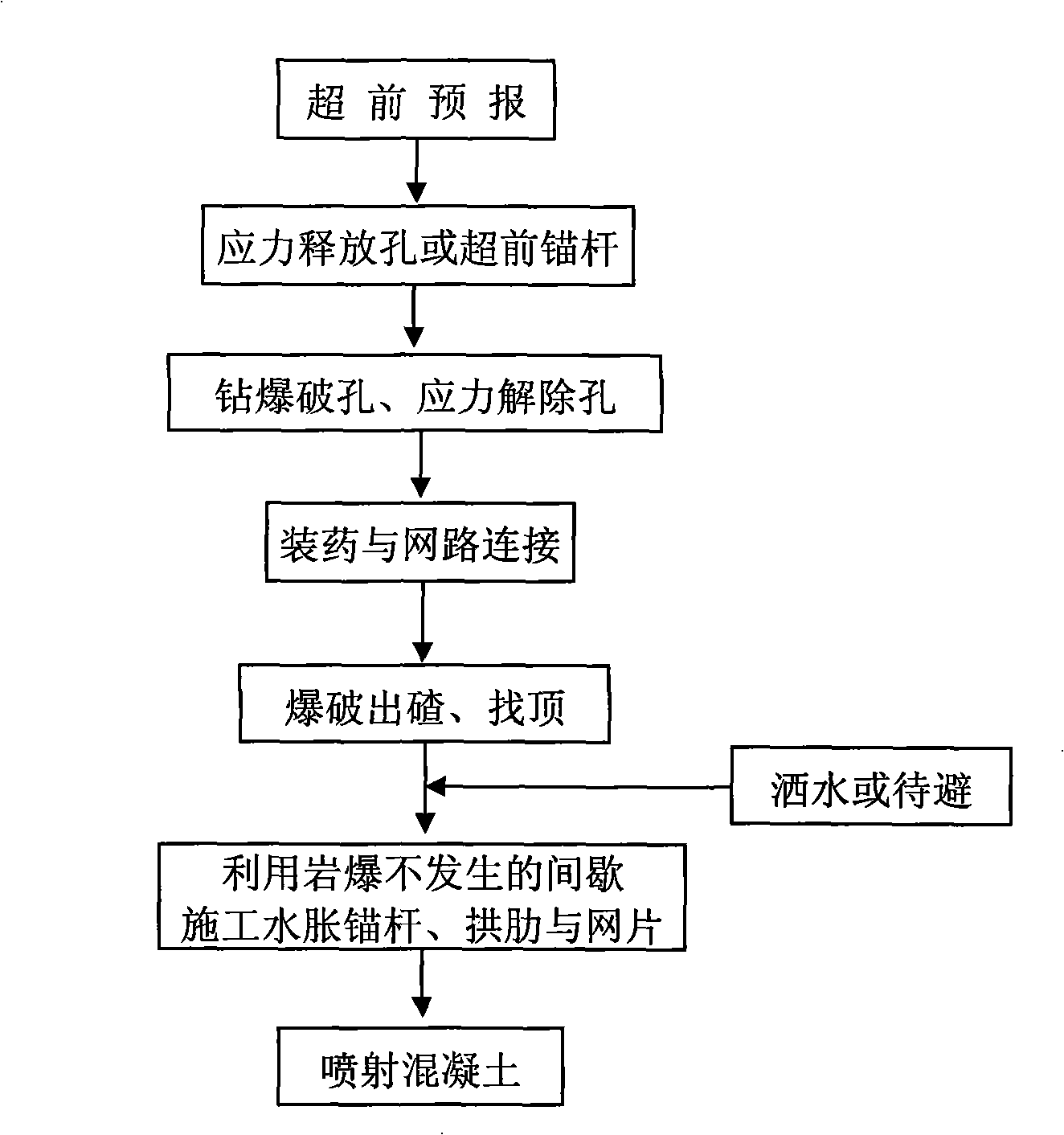

[0020] Such as figure 1 Shown is the construction process flowchart of the embodiment of the present invention.

[0021] The first step is to adopt the prediction method of rockburst or use the general geophysical prospecting method and engineering geological analysis method to analyze the geological conditions in front of the tunnel. When there is a strong to extremely strong rockburst, the following construction techniques are adopted:

[0022] In the second step, an advance release hole or an advance bolt is made in the vicinity where rock bursts are prone to occur. The hole depth of the advanced stress release hole is twice the blasting cycle footage, the hole diameter should not be less than φ48mm, the hole spacing should not be greater than 50cm, and the external inclination angle should be controlled at 5-15°; ~28mm, the hole spacing is 40~60cm, and the external inclination angle is controlled at 5~15°. At the same time, the exposed end is connected with the radial anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com