MTPA curve fitting method for embedded permanent magnet synchronous motor and control system

A permanent magnet synchronous motor and curve fitting technology, which is applied in the control system, vector control system, motor generator control, etc., can solve the problem that the MTPA curve cannot take into account the calculation and accuracy requirements at the same time, and achieve high precision and simple calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

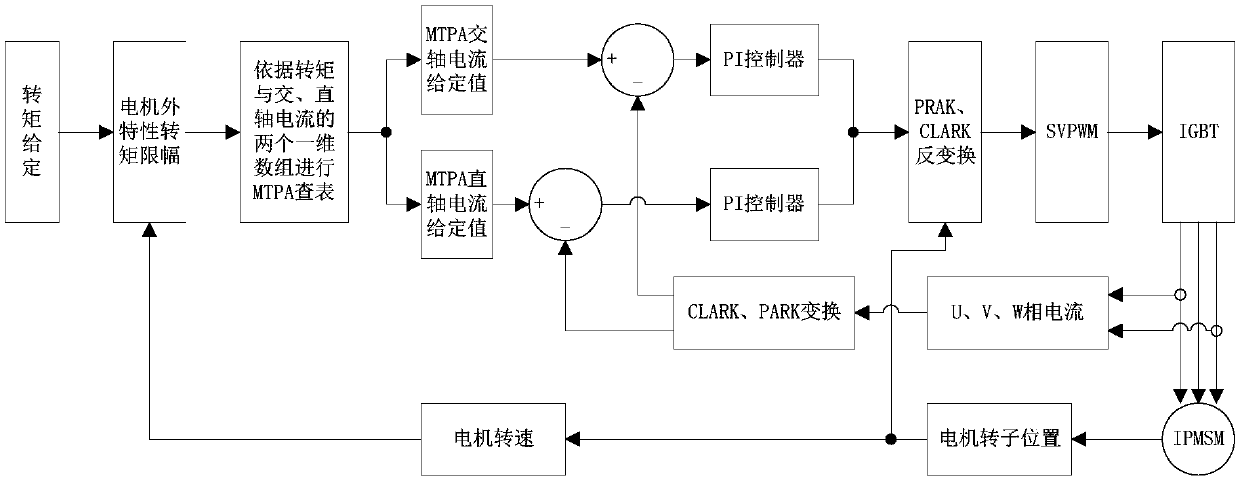

[0055] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

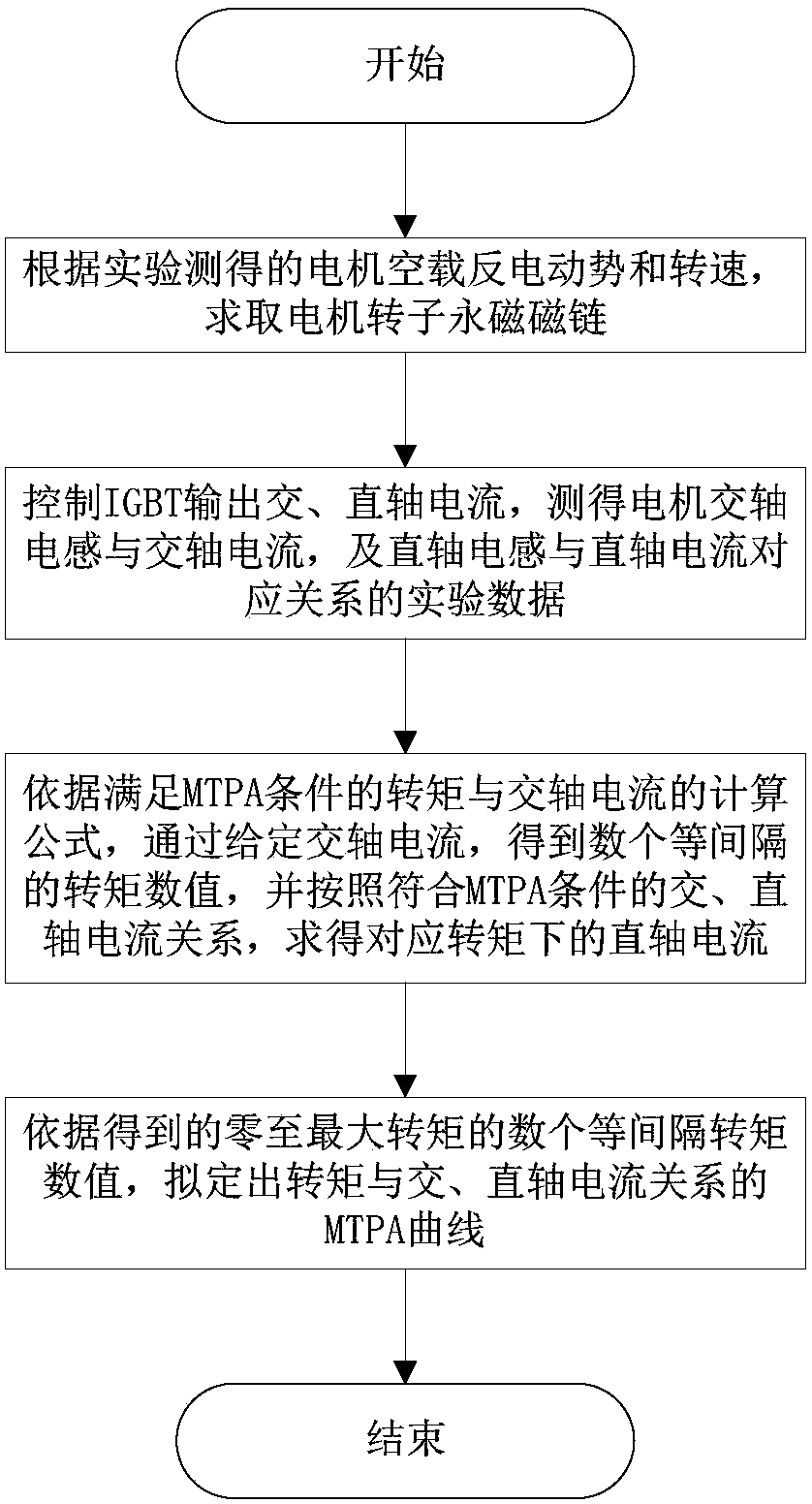

[0056] ⑴Develop the MTPA curve of the embedded permanent magnet synchronous motor

[0057] According to the no-load back electromotive force and speed measured by the experiment, the permanent magnet flux linkage of the motor rotor is obtained;

[0058] Control the IGBT to output AC and D-axis currents, and measure the experimental data of the motor's Q-axis inductance and Q-axis current, as well as the corresponding relationship between the D-axis inductance and the D-axis current;

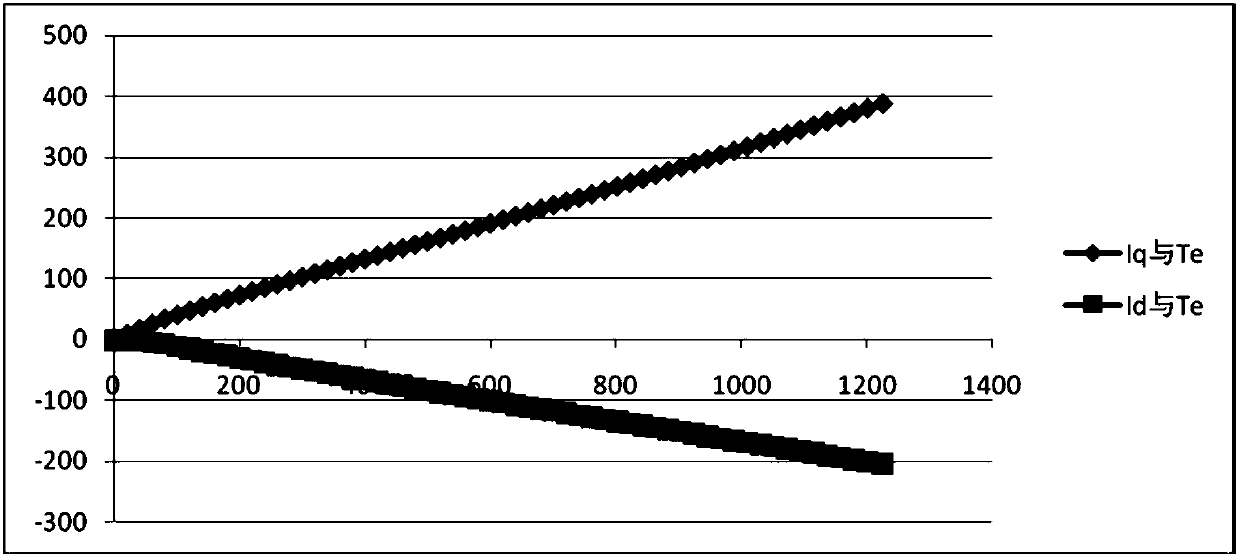

[0059] According to the calculation formula of the torque and the quadrature axis current satisfying the MTPA condition, by giving the quadrature axis current, several torque values at equal intervals are obtained, and the corresponding torque is obtained ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com