Plasma jet device and method for suppressing charge accumulation on epoxy resin surface

A technology of plasma and jet devices, applied in the direction of plasma, electrical components, coatings, etc., can solve the problems that are not suitable for large-scale industrial production applications, it is difficult to control the uniformity of various raw materials, and the production process requires high technical requirements. Suppresses the accumulation of surface charges, improves surface conductivity, and is inexpensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

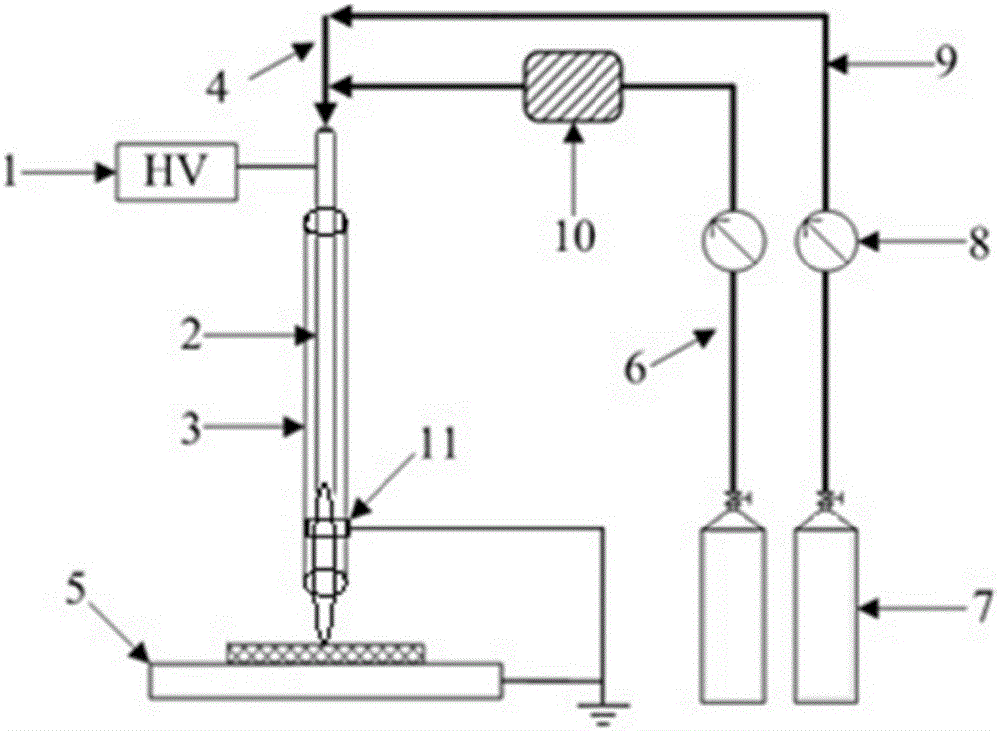

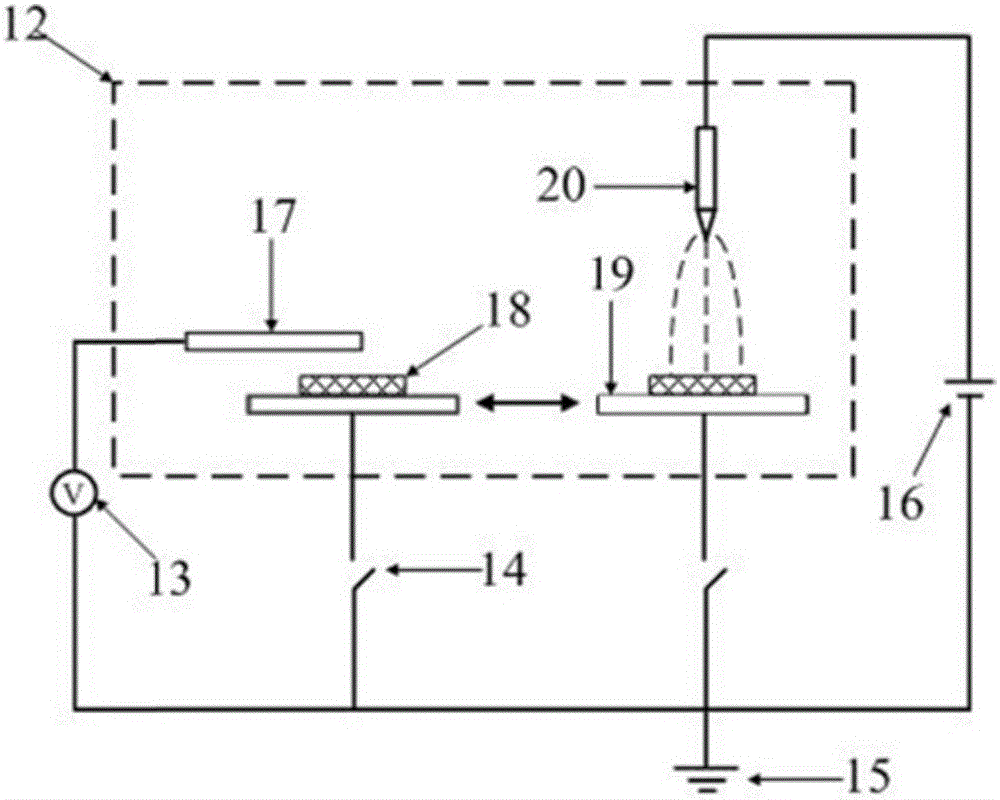

Method used

Image

Examples

Embodiment 1

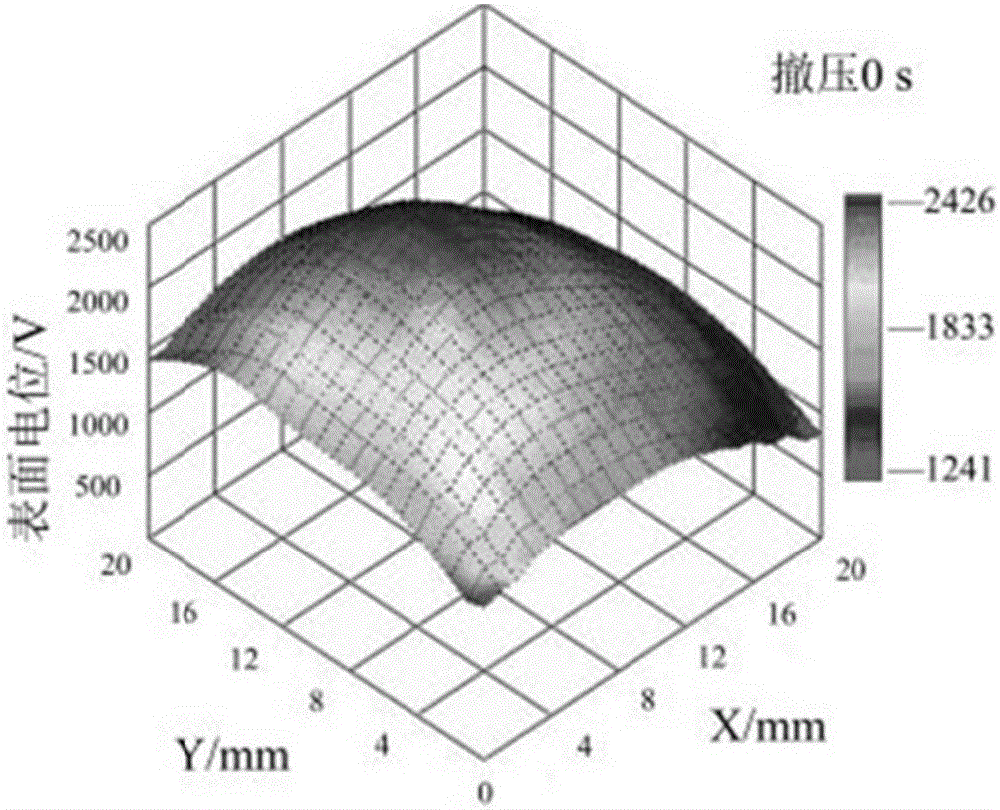

[0058] Use the surface potential measuring device to measure the surface potential of the untreated epoxy resin sample. Specifically, after charging for 1 min with a 5kV DC power supply, the voltages at the three moments of voltage withdrawal 0s, voltage withdrawal 900s, and voltage withdrawal 1800s are respectively measured. The surface potential is scanned and measured, and its three-dimensional distribution diagram is as follows Figure 3a ~ Figure 3c shown. When the pressure was removed for 0s, the surface potential distribution of the sample was conical, with an obvious bulge near the center of the sample, which decreased radially to the surroundings, and the highest potential point of 2426V was at the coordinate (8,16). After 900s and 1800s of depressurization, the surface potential distribution is still conical, and the surface potential decays rapidly in the first 900s of depressurization, and the highest value of the surface potential is 1105V after 1800s of depressur...

Embodiment 2

[0060] Atmospheric pressure plasma jet deposition was used to process 2mm thick epoxy resin samples, the discharge voltage amplitude was set to 18kV, the repetition frequency was 1500Hz, the jet nozzle was 10mm away from the sample surface, the inert gas was argon, the carrier gas flow rate was set to 500 sccm, and the excitation gas flow rate was set to For 2slm, the heating platform is preheated to 60°C, and the processing time is 60s.

[0061] Use the surface potential measuring device to measure the surface potential of the treated epoxy resin sample. Specifically, after charging with a 5kV DC power supply for 1min, the voltages at the three moments of voltage withdrawal 0s, voltage withdrawal 900s and voltage withdrawal 1800s are respectively measured. The surface potential is scanned and measured, and its three-dimensional distribution diagram is as follows Figure 3d ~ Figure 3e shown. When the pressure is removed for 0 s, the surface potential distribution of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com