Method for preparing lithium-ion secondary battery pole piece

A secondary battery, lithium ion technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex manufacturing process, high manufacturing cost, no thick pole pieces, etc., achieve high energy density, simple and easy preparation process The effect of line and rate performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

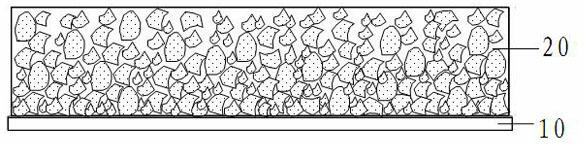

[0022] Embodiment 1: see figure 1 As shown, the pole piece prepared by the method of the present invention includes a current collector 10 and a diaphragm 20 arranged on the current collector 10, and the thickness of the diaphragm 20 is greater than or equal to 160 μm (preferably 160 to 3000 μm); From the surface of the current collector 10 to the direction away from the surface of the current collector 10, the porosity of the diaphragm 20 gradually increases.

[0023] Wherein, the pole piece includes a positive pole piece and a negative pole piece.

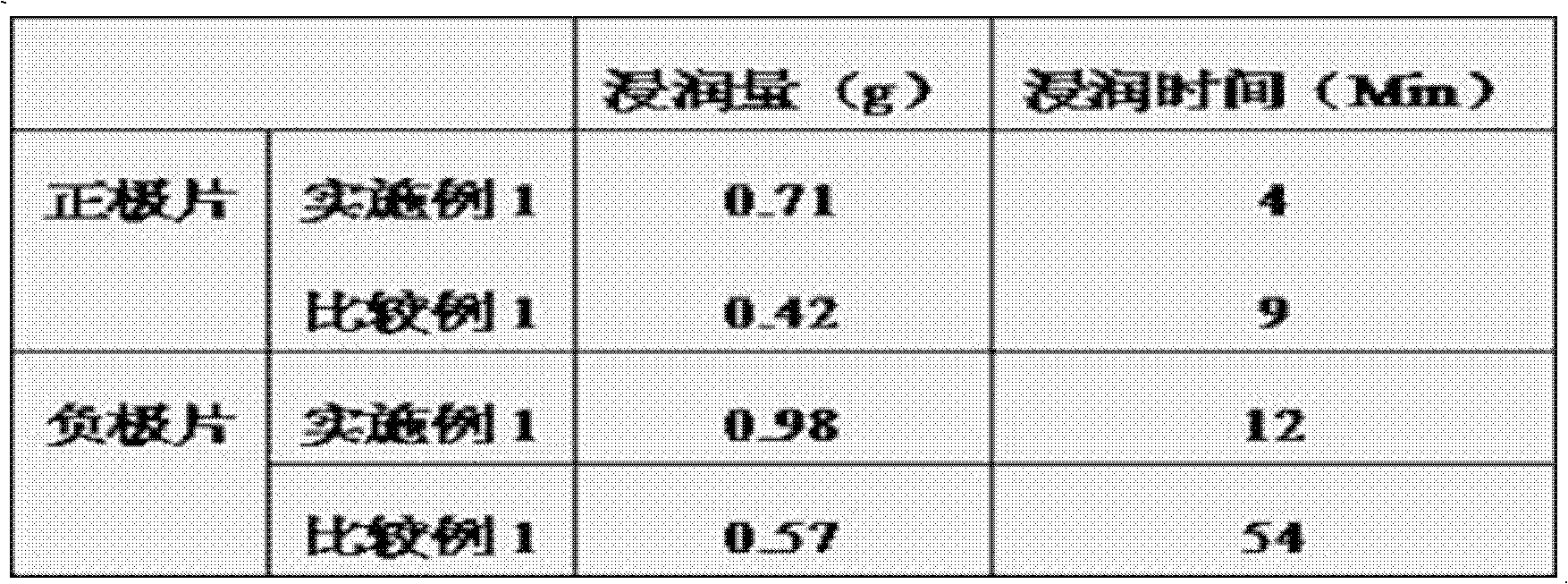

[0024] The production of the positive electrode sheet: the positive electrode active material lithium cobalt oxide (LiCoO 2), conductive agent carbon black, polymer binder polyvinylidene fluoride (PVDF) and dispersing solvent N-methylpyrrolidone (NMP) are uniformly mixed in a weight ratio of 96:2:2:80 to obtain a slurry, and then transfer Coating method The slurry is evenly coated on the aluminum foil current collector with a t...

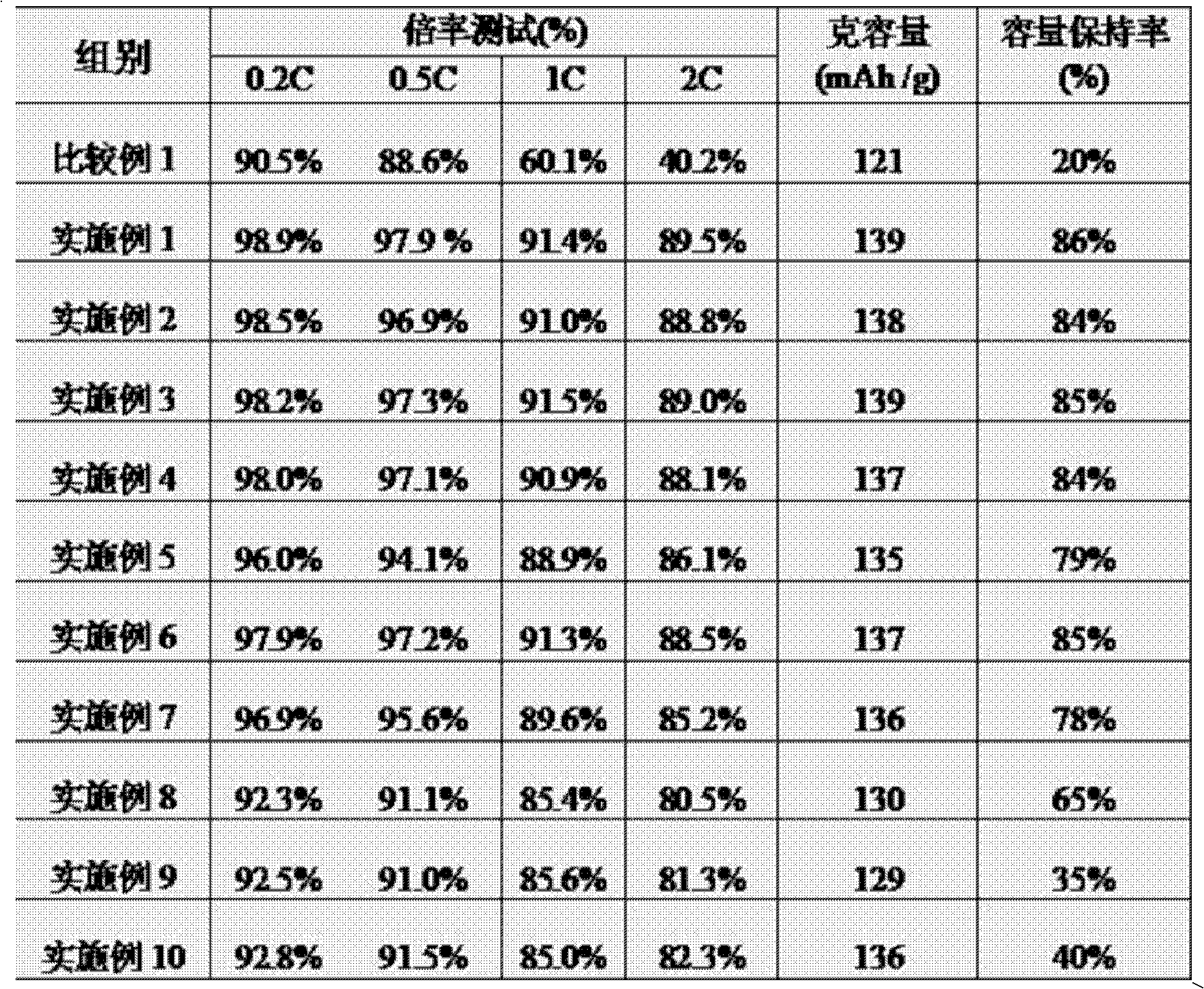

Embodiment 2

[0027] Embodiment 2: different from embodiment 1, the polymer binder in the making process of positive electrode plate is polyimide (PI), and dispersion solvent is dimethyl sulfoxide (DMSO), and non-solvent spraying quality is 5 wt% of the mass of the positive electrode active material, and the thickness of the positive electrode membrane is 250 μm. Lithium cobalt oxide (LiCoO 2 ), the mass ratio of conductive agent carbon black and polyimide (PI) is 94:3:3 in sequence.

[0028] The thickness of the negative electrode membrane is 250 μm.

[0029] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0030] Embodiment 3: Different from Example 1, the polymer binder in the production process of the positive electrode sheet is polyamide (PA), the dispersion solvent is dimethylformamide (DMF), and the non-solvent spraying quality is positive electrode activity 10 wt% of the mass of the substance, the thickness of the positive electrode membrane is 300 μm. Lithium cobalt oxide (LiCoO 2 ), the mass ratio of conductive agent carbon black and polyamide (PA) is 92:4:4 in sequence.

[0031] The thickness of the negative electrode membrane is 300 μm.

[0032] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com