High-tap-density nickel-cobalt-manganese laminated composite material and low-energy-consumption preparation method thereof

A lithium-nickel-cobalt-manganese compound technology is applied in the field of lithium-ion battery materials and their preparation, which can solve the problems of high requirements for reaction equipment, poor uniformity, and narrow particle size distribution, and achieves reduced synthesis costs, high discharge specific capacity, The effect of high magnification and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

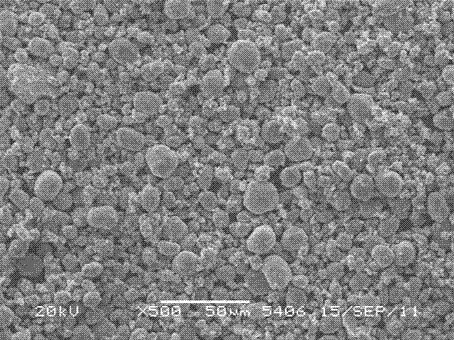

[0027] LiOH·H 2 O and Li 2 CO 3 According to its eutectic composition (molar ratio of 0.76:0.24), mix it with a mortar, and then mix it with the precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Mix in a molar ratio of 1.2:1. The mixture was placed in an alumina crucible, kept at 480 °C for 2 h in an air atmosphere, treated at 850 °C for 2 h, and then cooled to room temperature with the furnace to obtain spherical LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material (see figure 1 ), the tap density is 2.11 g / cm 3 .

[0028] The prepared material was used as the positive electrode material, the lithium sheet was used as the counter electrode, Celgard 2400 was used as the separator, and the electrolyte was 1.0 mol L -1 LiPF 6 / EC+DMC (EC:DMC=1:1 volume ratio), assembled into a CR2025 button cell in a stainless steel glove box filled with argon. The constant current constant voltage charge and discharge test is carried out on the Land BT2001A automatic battery test system, and the char...

Embodiment 2

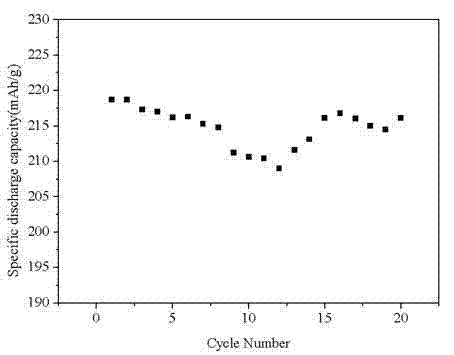

[0030] LiOH·H 2 O and Li 2 CO 3 Mix with a mortar according to its eutectic composition, and then mix with the precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 and LiCl were mixed at a molar ratio of 1.2:1:0.05, the mixture was placed in an alumina crucible, kept at 480°C for 2 h in an air atmosphere, treated at 850°C for 5 h, and then cooled to room temperature with the furnace to obtain spherical LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 1.95 Cl 0.05 , with a tap density of 2.00 g / cm 3 . Between 2.7-4.6V, the first discharge specific capacity at 0.1C is 218.7mAh / g, and after 20 cycles at 0.1C, the discharge specific capacity is 216.1mAh / g. The specific capacity of the first discharge at 0.2C is 208.6 mAh / g. The cycle life curve is attached image 3 shown. Test conditions such as embodiment 1.

Embodiment 3

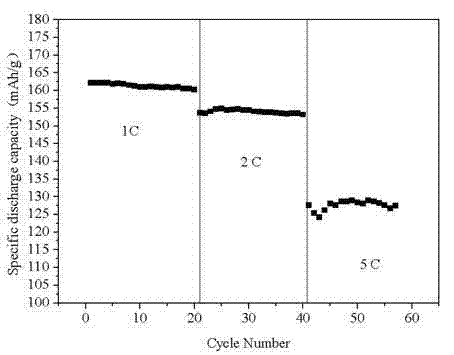

[0032] LiOH·H 2 O and Li2 CO 3 Mix with a mortar according to its eutectic composition, and then mix with the precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , LiBr were mixed at a molar ratio of 1.2:1:0.05, the mixture was placed in an alumina crucible, kept at 480°C for 2 h in an air atmosphere, treated at 900°C for 5 h, and then cooled to room temperature with the furnace to obtain spherical LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 1.95 Br 0.05 , with a tap density of 2.32 g / cm 3 . The first discharge capacity at 0.2C is 196.0 mAh / g. The cycle life curves at different magnifications are attached Figure 4 shown. The test conditions are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com