Biological flocculant and preparation method thereof

A biological flocculant and etherification agent technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., to achieve excellent solubility, obvious flocculation effect, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

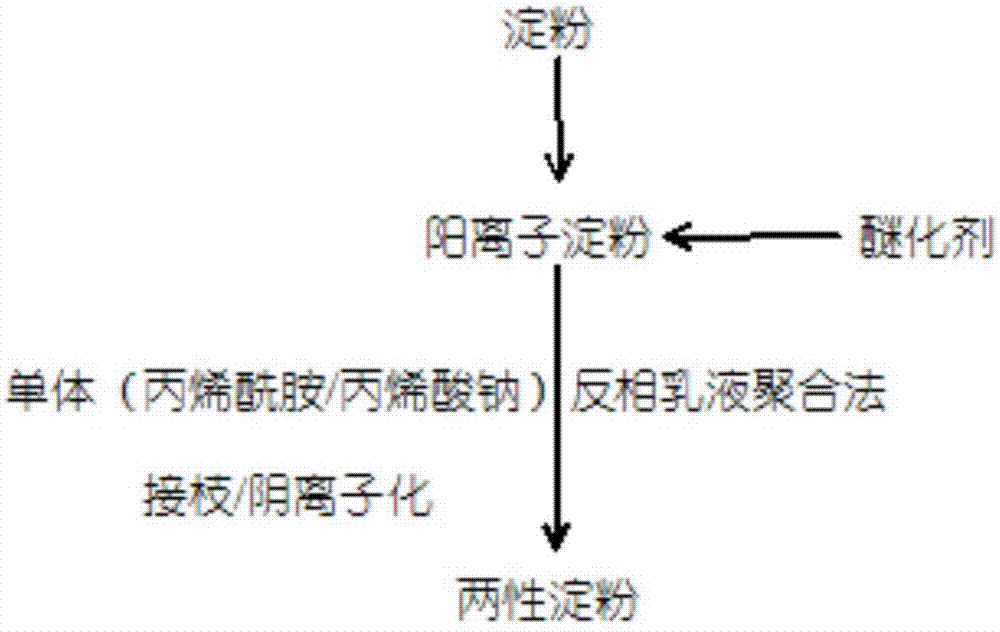

Method used

Image

Examples

Embodiment 1

[0050] (1) Dissolve NaOH in water, cool to room temperature, add etherifying agent 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA), and spray the solution containing NaOH and CTA on the dry starch , and stirred to make it evenly mixed, reacted at 70°C for 4 hours, then washed 2-5 times with 60% ethanol, and vacuum dried to prepare cationic starch; wherein, the molar ratio of NaOH to etherifying agent CTA is 1.5, the molar ratio of etherification agent CTA and dry starch is 0.45, and the mass fraction of water in the whole reaction system is 30%;

[0051] (2) Mill the cationic starch obtained in step (1) on a ball mill to obtain mechanically activated cationic starch, dissolve the mechanically activated cationic starch in water, heat it to gelatinize for 20 minutes, and then add the The liquid paraffin of the composite emulsifier is stirred with nitrogen gas, emulsified for 1 hour, and then the composite initiator ammonium persulfate-sodium bisulfite with an amount of ...

Embodiment 2

[0053] (1) Dissolve NaOH in water, cool to room temperature, add etherifying agent 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA), and spray the solution containing NaOH and CTA on the dry starch , and stirred to make it evenly mixed, reacted at 60°C for 6h, then washed 2-5 times with 60% ethanol, and vacuum dried to prepare cationic starch; wherein, the molar ratio of NaOH to etherifying agent CTA 0.8, the molar ratio of etherification agent CTA and dry starch is 0.2, and the mass fraction of water in the whole reaction system is 20%;

[0054] (2) Mill the cationic starch obtained in step (1) on a ball mill to obtain mechanically activated cationic starch, dissolve the mechanically activated cationic starch in water, heat it to make it gelatinize for 20 minutes, and then add the The liquid paraffin of the composite emulsifier is stirred with nitrogen gas, emulsified for 1 hour, and then the composite initiator ammonium persulfate-sodium bisulfite with an amount of 2...

Embodiment 3

[0056] (1) Dissolve NaOH in water, cool to room temperature, add etherifying agent 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA), and spray the solution containing NaOH and CTA on the dry starch , and stirred to make it evenly mixed, reacted at 80°C for 4 hours, then washed 2-5 times with 60% ethanol, and vacuum dried to prepare cationic starch; wherein, the molar ratio of NaOH to etherifying agent CTA is 1.5, the molar ratio of etherification agent CTA and dry starch is 0.6, and the mass fraction of water in the whole reaction system is 25%;

[0057] (2) Mill the cationic starch obtained in step (1) on a ball mill to obtain mechanically activated cationic starch, dissolve the mechanically activated cationic starch in water, heat it to make it gelatinize for 20 minutes, and then add The liquid paraffin of the composite emulsifier is stirred with nitrogen gas, emulsified for 1 hour, and then the compound initiator ammonium persulfate-sodium bisulfite with an amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com