Paper fold-resistance reinforcing agent and preparation method thereof

A technology of strengthening agent and folding resistance, applied in the field of preparation of paper strengthening agent, can solve the problems of complex production process of wood pulp ratio, high production cost, multiple wood resources, etc., achieve excellent film-forming properties, improve ring compressive strength and Bursting strength, good affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

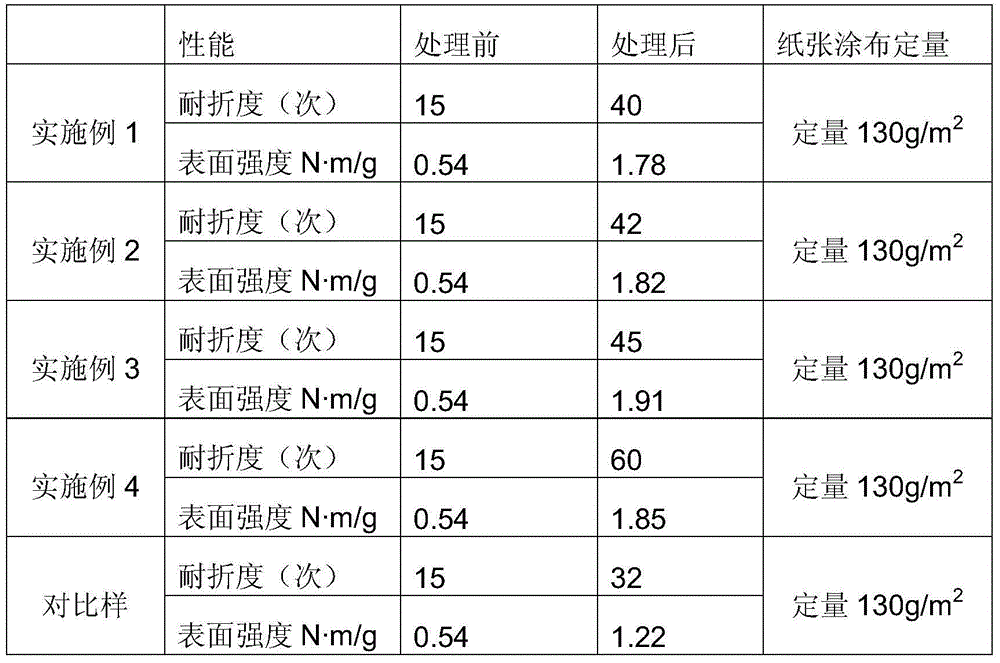

Examples

Embodiment 1

[0031] (1) Add 10g sodium hydroxide and 50g sodium hypochlorite (9% available chlorine) in 1000g water, stir until there is no insoluble matter, add cornstarch 200g (moisture is 13%) while stirring, obtain starch milk after stirring, Heat to 95°C, heat-preserve and gelatinize for 10 minutes, then add 14.5g of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (mass concentration is 69%), continue to react at 95°C for 60 minutes, and obtain amphoteric starch solution ;

[0032] (2) Add 5.22 g of polyamide polyamine epoxy resin to (1), and react at 95° C. for 30 minutes; reduce the system temperature to 80° C.;

[0033] (3) Add 8.7 g of cationic polyacrylamide to (2), react at 80°C for 60 minutes, and cool down to room temperature to obtain a folding strength enhancer.

Embodiment 2

[0035] (1) In 1000g of water, add 30g of sodium hydroxide and 10g of potassium persulfate, stir evenly until there is no insoluble matter, under stirring, add 150g of tapioca starch (moisture is 13%), stir to obtain starch milk, add Raise the temperature to 80°C, heat-preserve and gelatinize for 20 minutes, then add 20g of 2,3-epoxypropyltrimethylammonium chloride (mass concentration: 50%), and continue the reaction at 80°C for 30 minutes to obtain an amphoteric starch solution;

[0036] (2) Add 7.83 g of polyamide polyamine epoxy resin to (1), and react for 40 minutes at 80° C.;

[0037] (3) Add 27.84 g of anionic polyacrylamide to (2), react at 80° C. for 60 minutes, and cool down to room temperature to obtain a folding strength enhancer.

Embodiment 3

[0039] (1) add 10g sodium hydroxide and 40g sodium hypochlorite (9% available chlorine) in 1000g water, stir until there is no insoluble matter, add potato starch 200g (moisture is 13%) while stirring, obtain starch milk after stirring, Heat to 70°C, heat-preserve and gelatinize for 30 minutes, then add 20g of N-(2,3-epoxypropyl)diethylamine solution (mass concentration: 69%), continue to heat-retain at 70°C for 60 minutes, and obtain amphoteric starch solution ;

[0040] (2) Add 10.44 g of polyamide polyurea cyclic resin to (1), heat-retain and react at 70°C for 60 minutes, then cool down to 60°C;

[0041] (3) Add 17.4 g of amphoteric polyacrylamide to (3), heat-retain and react at 60°C for 90 minutes, and cool down to room temperature to obtain a folding strength enhancer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com