Preparation method for cross-linked amphoteric starch

A technology of amphoteric starch and starch, which is applied in the field of starch modification, can solve the problems of complex process, high price of cationization and anionization reagents, and achieve the effect of simple process, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

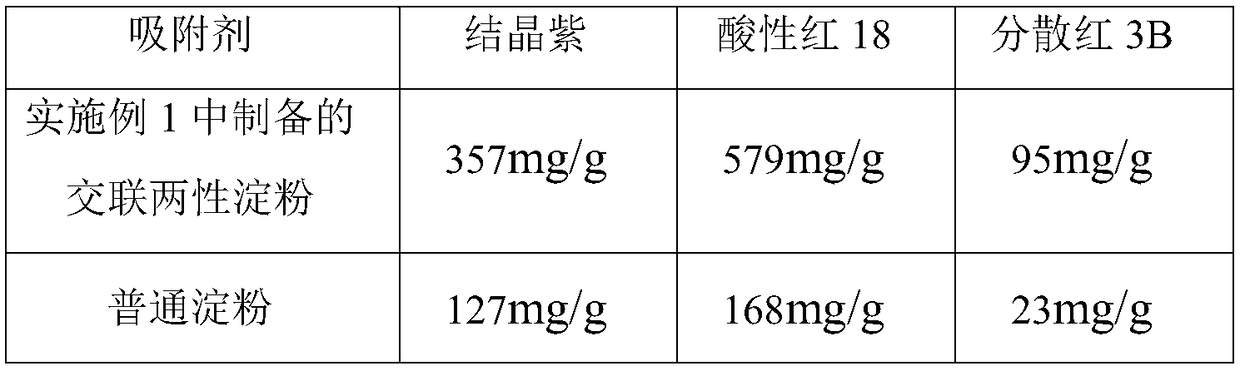

Examples

preparation example Construction

[0021] A preparation method of cross-linked amphoteric starch, specifically implemented according to the following steps:

[0022] Step 1. Weigh the starch and water according to the mass ratio of starch and water of 0.05-0.1:1, disperse the starch into water, stir and disperse at 70-90°C for 0.5-2h, and obtain gelatinized starch, wherein, starch Any one of potato starch, corn starch, sweet potato starch, tapioca starch, wheat starch, mung bean starch;

[0023] Step 2, add cationic monomer and anionic monomer to gelatinized starch, after stirring for 30min, obtain mixture A, wherein, the mass ratio of cationic monomer and water and the mass ratio of anionic monomer and water are 0.01-0.05: 1; The cationic monomer is any one of methacryloyloxyethyltrimethylammonium chloride, acryloyloxyethyltrimethylammonium chloride, and dimethyldiallylammonium chloride; the anionic monomer The body is any one of sodium acrylate, potassium acrylate, and acrylic acid;

[0024] Step 3. Add a c...

Embodiment 1

[0027] A preparation method of cross-linked amphoteric starch, specifically implemented according to the following steps:

[0028] Step 1. Add 5g of potato starch to 100g of water, stir and disperse at 90°C for 0.5h to obtain gelatinized starch;

[0029] Step 2, adding 1 g of methacryloyloxyethyltrimethylammonium chloride and 1 g of sodium acrylate to the gelatinized starch, and stirring for 30 minutes to obtain a mixture A;

[0030] Step 3. Add 0.1g of N,N-methylenebisacrylamide to the mixture A, add 0.1g of potassium persulfate after mixing evenly, stir and react at 40°C for 48h, and obtain a gel-like product;

[0031] Step 4: Soak and wash the gel-like product with deionized water for 5 times, and dry to constant weight to obtain cross-linked amphoteric starch.

Embodiment 2

[0033] A preparation method of cross-linked amphoteric starch, specifically implemented according to the following steps:

[0034] Step 1. Add 10g of cornstarch to 100g of water, stir and disperse at 70°C for 2 hours to obtain gelatinized starch;

[0035] Step 2. Add 5g of acryloyloxyethyltrimethylammonium chloride and 5g of potassium acrylate to the gelatinized starch, and stir for 30min to obtain mixture A;

[0036] Step 3. Add 0.4 g of divinylbenzene to the mixture A, add 0.5 g of ammonium persulfate after mixing evenly, and stir and react at 80°C for 24 hours to obtain a gel-like product;

[0037] Step 4. Soak and wash the gel-like product 10 times with deionized water, and dry to constant weight to obtain cross-linked amphoteric starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com