Paper having enhanced dry strength and wet strength

A technology of dry strength and wet strength, applied in the direction of reinforcing agent addition, textile and papermaking, paper, etc., can solve the problems of low paper strength, environmental pollution, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

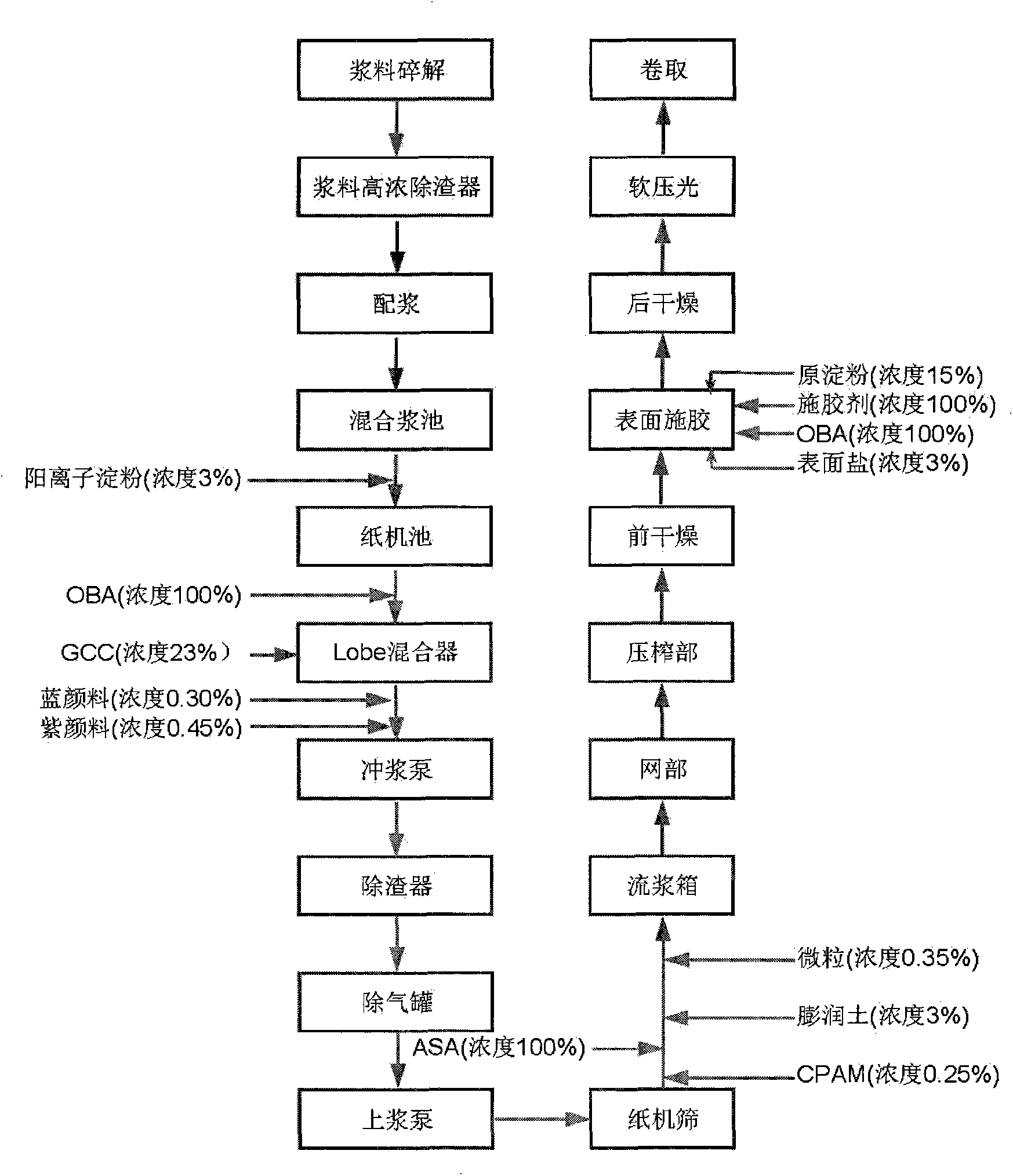

Method used

Image

Examples

Embodiment

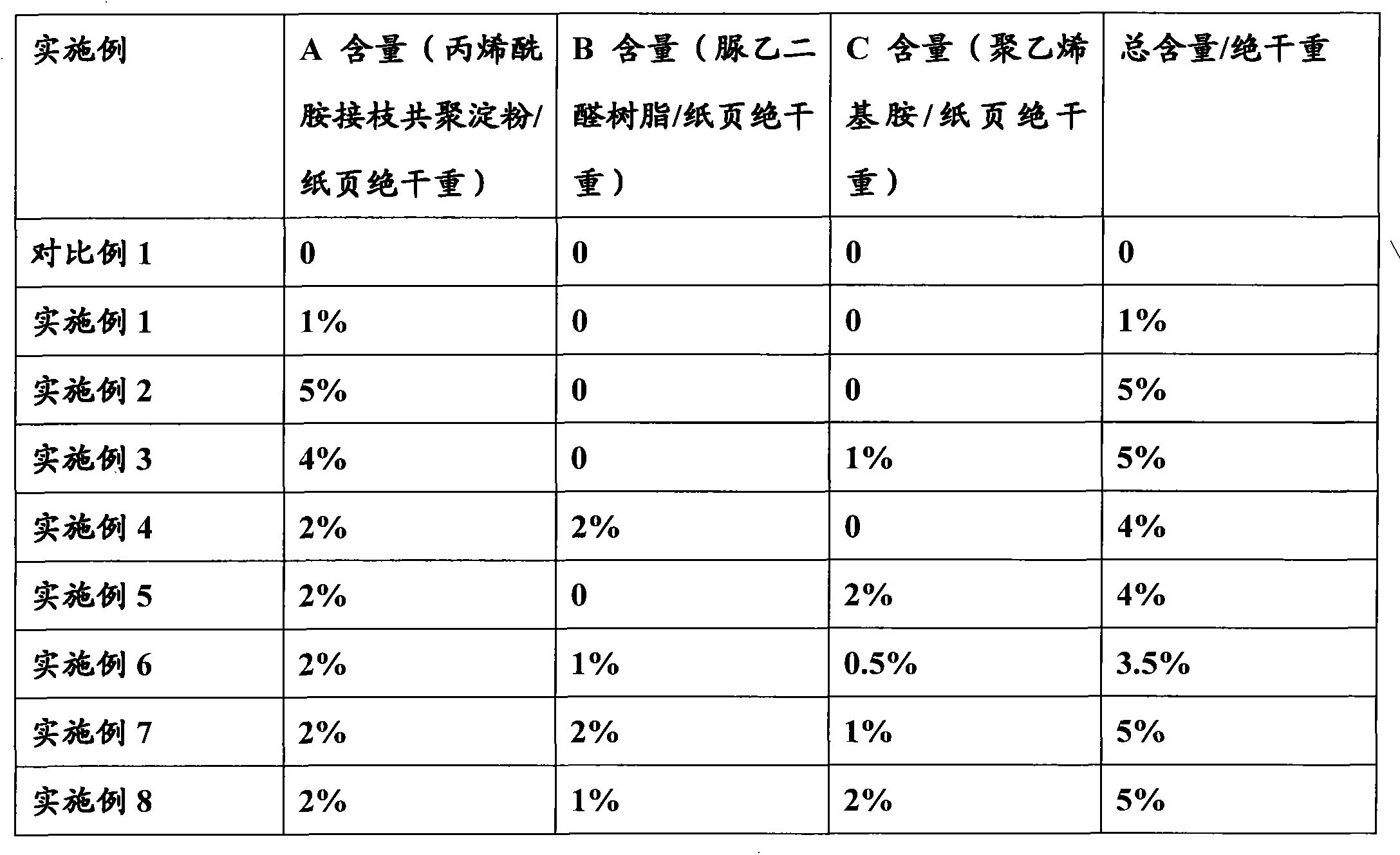

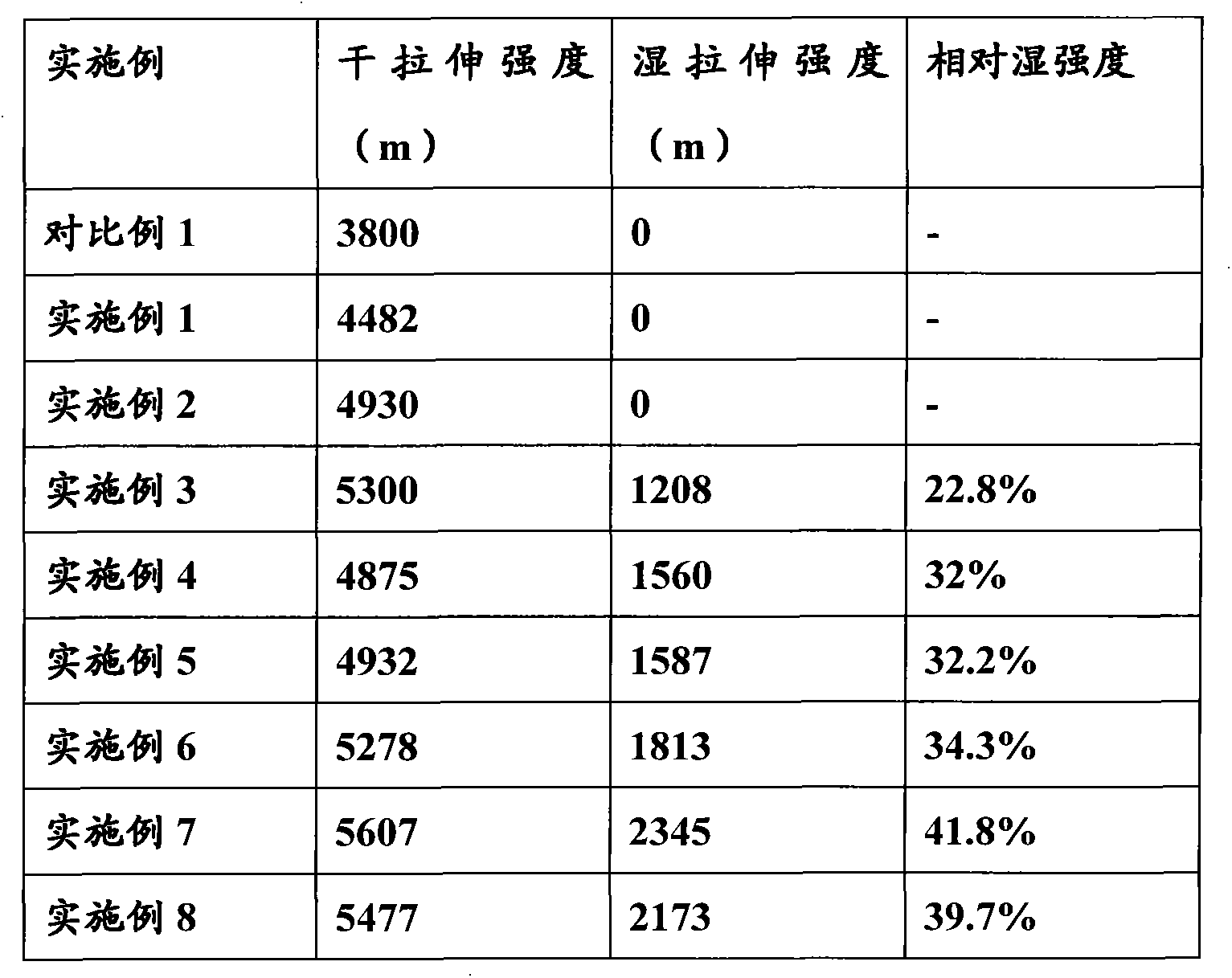

[0064] The percentages in the examples are by weight. The dry breaking length is measured according to DIN53112sheet1. The wet breaking length is measured according to DIN53112sheet2.

[0065] Preparation of Acrylamide Graft Copolymerized Starch

[0066] Weigh a certain amount of starch (for example, obtained from Kemira Chemicals), add water, pass N in a water bath at 85°C 2 Stir and gelatinize for 1h, then add about 1wt% of initiator cerium ammonium nitrate and acrylamide, the mass ratio of starch to acrylamide is 1:1.5, react at 35°C for 3h, the grafting rate can reach 90%, and the solid content is 34 %, the viscosity is the acrylamide grafted co-polymerized starch A of 585mPa.s.

[0067] Preparation of urea glyoxal resin

[0068] The molar ratio of the total amount of glyoxal to urea is 1.5-2.0:1.0, the glyoxal is added in two times, the molar ratio of the first addition of glyoxal to the second addition of glyoxal is 9:1, the specific process It is prepared by the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com