Amphoteric starch for AKD emulsification and preparation method and applications thereof

An amphoteric starch, starch technology, applied in textiles and papermaking, water repellent addition, paper and other directions, can solve the problems of emulsion surface crusting, poor emulsion stability, poor stability, etc., and achieve uniform size distribution, low cost, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

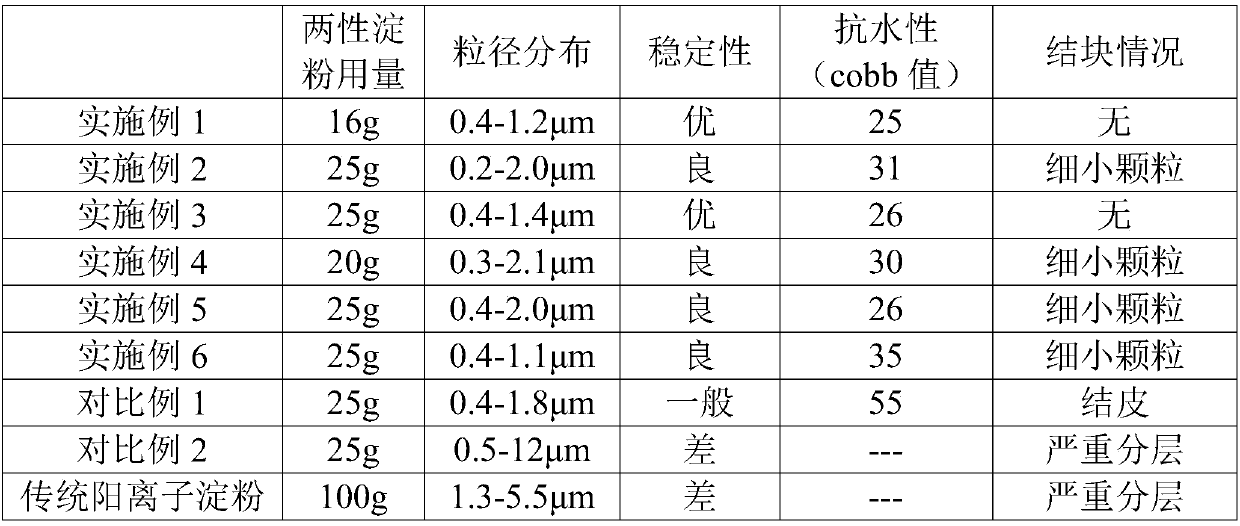

Examples

Embodiment 1

[0031] A kind of preparation method of amphoteric starch for AKD emulsification of the present embodiment, the steps are as follows:

[0032] (1) 50 parts by weight of starch (tapioca starch) with a water content between 5% and 15% are added to a mixed solution of 100 parts by weight of water and an organic solvent (the weight ratio is 20:80, and the organic solvent is isopropanol) After stirring evenly, slowly add 5 parts by weight of alkali (sodium hydroxide) into the solution, and stir for 60 minutes.

[0033] (2) Heat the solution to 70°C. After the temperature stabilizes, add 8 parts by weight of cationic etherification agent (3-chloro-2-hydroxypropyl-trimethylammonium chloride) dropwise to the solution, and continue stirring for 3 Hour.

[0034] (3) Add 1 part by weight of a viscosity reducer (30% aqueous hydrogen peroxide solution by volume) to the solution, and continue to stir and react for 1.5 hours.

[0035] (4) Add 3 parts of anionic etherification agent (succini...

Embodiment 2

[0038] A kind of preparation method of amphoteric starch for AKD emulsification of this embodiment, the raw material and preparation method that it adopts are the same as embodiment 1, difference is:

[0039] In step (4), the anionic etherification agent used is sodium chloroacetate.

Embodiment 3

[0041] A kind of preparation method of amphoteric starch for AKD emulsification of this embodiment, the raw material and preparation method that it adopts are the same as embodiment 1, difference is:

[0042] In step (4), the cationic etherification agent used is 2,3-epoxypropyl-trimethylammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com