Dry strength agent, preparation method thereof and slurry using dry strength agent

A technology of increasing dry strength agent and reaction, applied in the direction of reinforcement agent addition, etc., which can solve the problems of short storage time, low solid content, white water pollution and other problems of slurry, and achieve easy pollution, strong winding degree, retention and filtration The effect of water up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

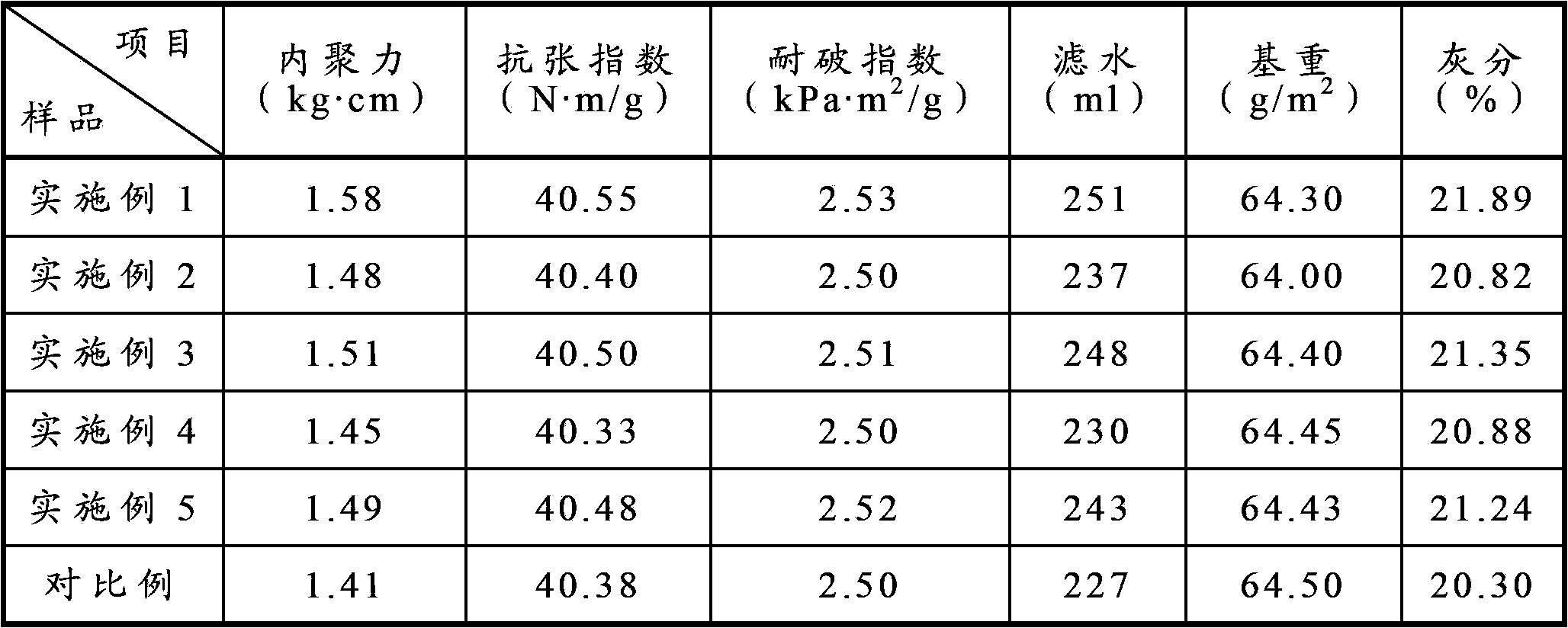

Examples

preparation example Construction

[0014] The preparation method of the dry strengthening agent of the preferred embodiment of the present invention comprises the following steps:

[0015] (1) Prepare the original starch liquid.

[0016] Take a certain amount of raw starch, add water and mix evenly to make a raw starch liquid with a concentration of 30%-60% by mass. The native starch can be any one of potato native starch, tapioca native starch, corn native starch or wheat native starch.

[0017] (2) Add etherification agent and alkali.

[0018] Add cationic etherifying agent, anionic etherifying agent and alkali to the above raw starch liquid at the same time, mix evenly, then raise the temperature to 60-80° C. and react for 1-3 hours to obtain amphoteric starch liquid.

[0019] The cationic etherifying agent and the anionic etherifying agent act on the original starch at the same time to generate amphoteric starch in one step. The etherification reaction needs to be carried out under an alkaline environmen...

Embodiment 1

[0047]Preparation of dry strengthening agent: take 200g of cassava raw starch, add water to prepare a raw starch liquid with a mass concentration of 40%, add 3-chloro-2 -Hydroxypropyl-trimethylammonium chloride, then add 4% monochloroacetic acid solution relative to the dry weight of the original starch, stir evenly, add 40% sodium hydroxide aqueous solution, control sodium hydroxide and etherification agent The molar ratio of the mixture is 2.0:1. After mixing and stirring evenly, heat up to 80°C for 2 hours. After the reaction, add 5% PAE relative to the dry weight of the original starch into the etherified amphoteric starch liquid, and heat up to 95°C for reaction. After 40 minutes, the temperature was lowered to 80°C, and cationic polyacrylamide powder with a molecular weight of about 500,000 was added in an amount of 10% of the dry weight of the original starch, and then water was added to adjust the total solid content to 15%. After 60 minutes of reaction, the temperature...

Embodiment 2

[0050] Preparation of dry strengthening agent: take 200g of potato raw starch, add water to prepare a raw starch solution with a mass concentration of 50%, add 3-chloro-2 -Hydroxypropyl-trimethylammonium chloride and 3% N-(2,3-epoxypropyl) diethylamine, then add 2% monochloroacetic acid solution relative to the dry weight of the original starch, stir After uniformity, add 40% sodium hydroxide aqueous solution, control the molar ratio of sodium hydroxide and etherification agent to 2.5:1, mix and stir evenly, then raise the temperature to 70°C and react for 2 hours. After the reaction, add etherified amphoteric starch Add 3% PAE relative to the dry weight of the original starch into the solution, raise the temperature to 120°C for 30 minutes, then cool down to 65°C, add anionic polyacrylamide powder with a molecular weight of about 400,000, and the amount added is 1% of the dry weight of the original starch. After adding water to adjust the total solid content to 20%, after rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com