Method for preparing amphoteric starch

An amphoteric starch and starch technology, applied in the field of starch modification, can solve the problems of easy loss, unstable product performance, etc., and achieve the effects of easy biodegradation, wide application range and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

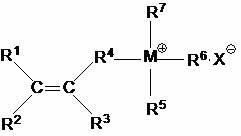

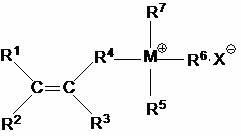

Image

Examples

Embodiment 1

[0031] Example 1 (Simultaneous grafting of anion and cation monomers)

[0032] Mix 20 grams of cornstarch (dry basis) with 200 milliliters of distilled water evenly, gelatinize at 85°C for 30 minutes, and lower the temperature to room temperature. Add 4.69 grams of acrylamide (0.066mol), 10.80 grams of methacryloyloxyethyltrimethylammonium chloride (0.052mol), 6.21 grams of sodium acrylate (0.066mol), and 0.2 grams of cerium ammonium nitrate in sequence, and stir evenly. The air was purged with nitrogen gas for 30 minutes. Then the temperature was raised to 55° C., and the reaction was carried out for 3 hours. Cooling to room temperature afforded a viscous crude product. The crude product was baked in a constant temperature oven at 130°C for 2 hours, cooled to room temperature, pulverized, and dried in a vacuum oven at 50°C until constant weight. Cross 100 mesh sieves to obtain amphoteric starch powder.

[0033] Purification method: take the amphoteric starch powder as th...

Embodiment 2

[0037] Example 2 (Graft cationic monomer first, then graft anionic monomer)

[0038] After mixing 30 g of soluble cornstarch with 50 ml of distilled water, 3.55 g of vinylbenzyltributylphosphonium chloride (0.010 mol), 1.78 g of acrylamide (0.025 mol), and 0.1 g of potassium persulfate were added in sequence. After mixing evenly, heat up to 50°C, add 5 ml of aqueous solution containing 0.1 g of sodium bisulfite, and react for 3.5 hours. Then, 1.03 g of sodium acrylate (0.011 mol), 1.78 g of acrylamide (0.025 mol), and 0.1 g of potassium persulfate were added. After mixing evenly, heat up to 55°C, add 5 ml of aqueous solution containing 0.1 g of sodium bisulfite, and react for 3.5 hours.

[0039] Cooling to room temperature afforded wet crude product. The crude product was baked in a constant temperature oven at 130°C for 2 hours, cooled to room temperature, pulverized, and dried in a vacuum oven at 50°C until constant weight. Cross 100 mesh sieves to obtain amphoteric starc...

Embodiment 3

[0041] Example 3 (Graft anion first, then graft cation)

[0042] After mixing 30 grams of potato starch evenly with 400 milliliters of distilled water, gelatinize at 85° C. for 20 minutes, and lower the temperature to room temperature to obtain starch paste. 10.34 g of sodium acrylate (0.110 mol), 7.11 g of acrylamide (0.100 mol), and 0.1 g of ammonium persulfate were added. After mixing evenly, the temperature was raised to 40° C., 5 ml of an aqueous solution containing 0.1 g of sodium sulfite was added, and the mixture was reacted for 4 hours. Then, 4.15 g of p-vinylbenzyltriphenylphosphonium chloride (0.010 mol), 16.17 g of dimethyldiallylammonium chloride (0.100 mol) and 7.11 g of acrylamide (0.100 mol), 0.1 g of over Ammonium sulfate, after mixing evenly, raised the temperature to 40°C, added 5 ml of aqueous solution containing 0.1 g of sodium sulfite, and reacted for 4 hours.

[0043] Cooling to room temperature afforded a viscous crude product. The crude product wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com